Preparation method of few-layer hexagonal boron nitride

A technology of hexagonal boron nitride and boron nitride powder, which is applied in the field of nanomaterials and can solve problems such as low yield, potential safety hazards, and limited application scenarios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Using hexagonal boron nitride powder as raw material, put the high-temperature-resistant stainless steel containing hexagonal boron nitride powder in a muffle furnace, then heat it in the air to a certain temperature and keep it for a certain period of time, then pour water into it to quench and cool to room temperature, and centrifuge Obtain the supernatant. Specifically include the following steps:

[0024] A preparation method for few-layer hexagonal boron nitride is characterized in that it specifically comprises the following steps:

[0025] Step 1. Place the high-temperature stainless steel container containing boron nitride powder in a muffle furnace at room temperature;

[0026] Step 2. Start heating, raise the temperature to 600°C, and keep it warm for 10 minutes;

[0027] Step 3. After the heat preservation is over, take out the container, quickly pour cold water into it, and quench the boron nitride;

[0028] Step 4. After cooling, centrifuge and take the ...

Embodiment 2

[0031] Using hexagonal boron nitride powder as raw material, put the high-temperature-resistant stainless steel containing hexagonal boron nitride powder in a muffle furnace, then heat it in the air to a certain temperature and keep it for a certain period of time, then pour cold water into it to quench and cool to room temperature, and centrifuge Obtain the supernatant. Specifically include the following steps:

[0032] A preparation method for few-layer hexagonal boron nitride is characterized in that it specifically comprises the following steps:

[0033] Step 1. Place the high-temperature stainless steel container containing boron nitride powder in a muffle furnace at room temperature;

[0034] Step 2. Start heating, raise the temperature to 800°C, and keep it warm for 2 hours;

[0035] Step 3. After the heat preservation is over, take out the container, quickly pour cold water into it, and quench the boron nitride;

[0036] Step 4. After cooling, centrifuge and take th...

Embodiment 3

[0039] Using hexagonal boron nitride powder as raw material, put the high-temperature-resistant stainless steel containing hexagonal boron nitride powder in a muffle furnace, then heat it in the air to a certain temperature and keep it for a certain period of time, then pour water into it to quench and cool to room temperature, and centrifuge Obtain the supernatant. Specifically include the following steps:

[0040] Step 1. Place the high-temperature stainless steel container containing boron nitride powder in a muffle furnace at room temperature;

[0041] Step 2. Start heating, raise the temperature to 1000°C, and keep it warm for 4 hours;

[0042] Step 3. After the heat preservation is over, take out the container, quickly pour cold water into it, and quench the boron nitride;

[0043] Step 4. After cooling, centrifuge and take the supernatant to obtain a sample.

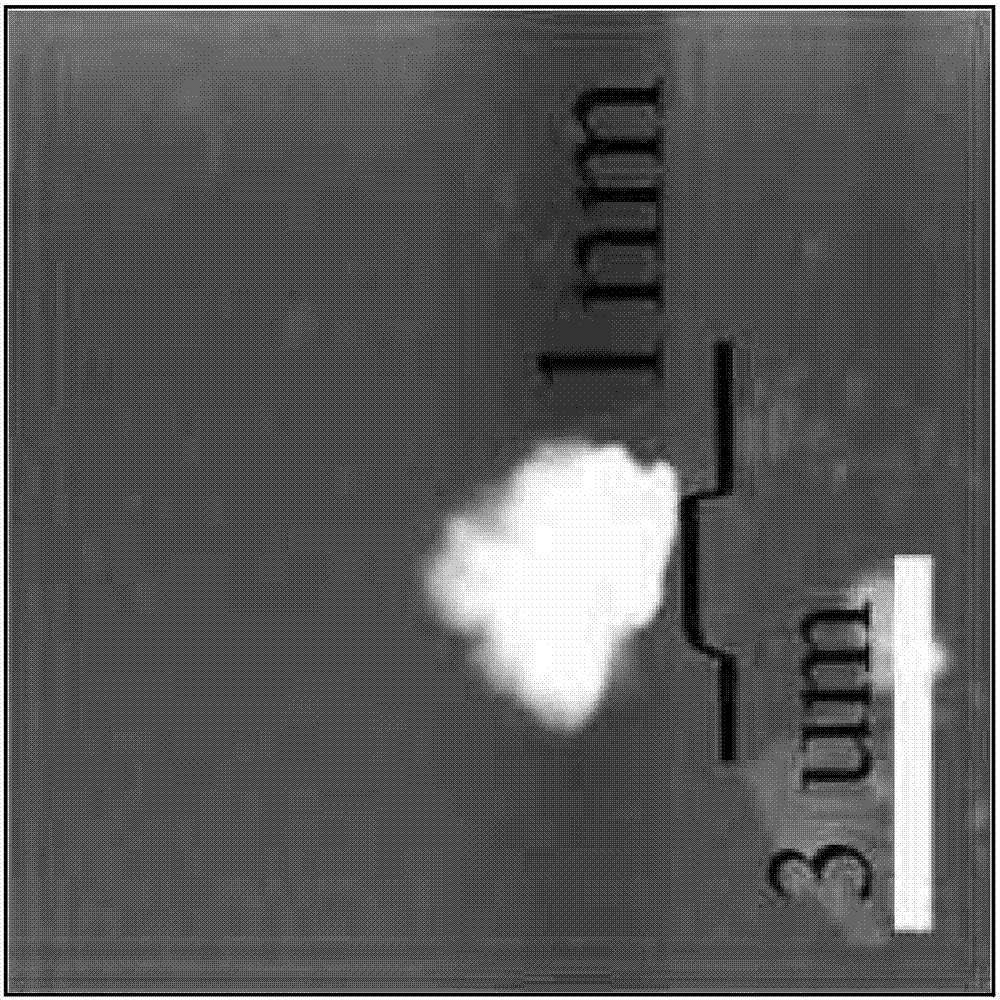

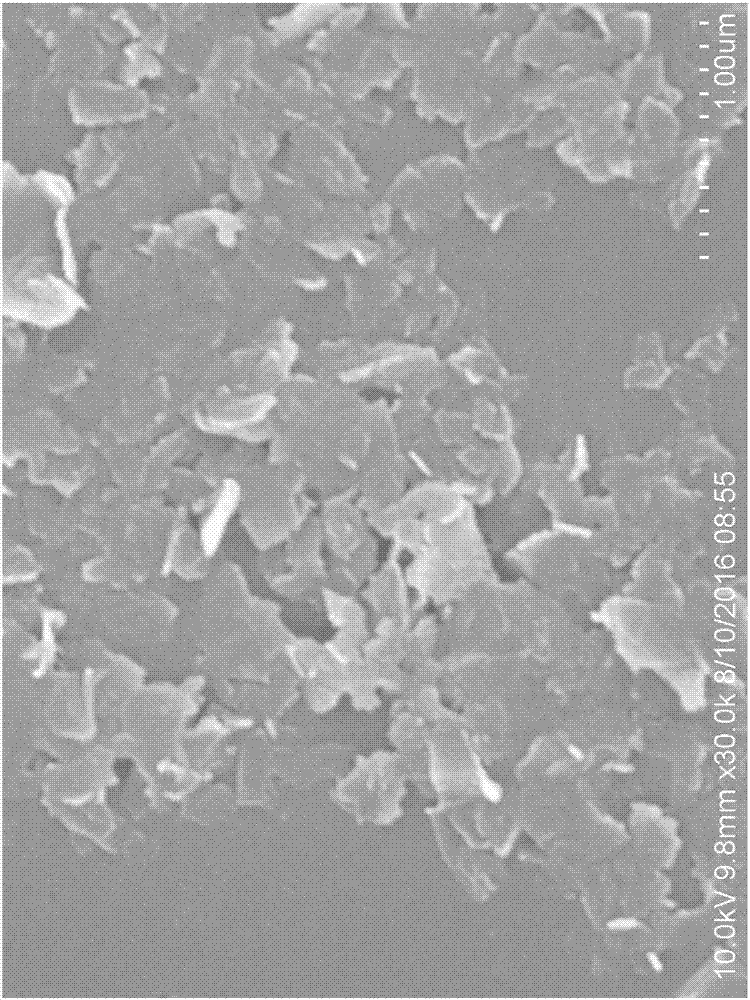

[0044] The samples were characterized by atomic force microscope and scanning electron microscope, the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com