A kind of preparation method of lotus root juice beverage

A lotus root juice and beverage technology, applied in the field of preparation of lotus root juice beverages, can solve the problems of unsuitability for industrial processing of lotus root juice beverages, low phenol content of polyphenol beverages, large loss of polyphenol components, etc., and save labor costs , Increase polyphenol content, improve antioxidant activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a preparation method of lotus root juice beverage, which uses whole lotus root as raw material, comprising the following steps:

[0026] 1) Wash and slice the whole lotus root and soak it in the color-protecting solution to obtain color-protecting lotus root slices;

[0027] 2) mixing the color-protecting lotus root slices obtained in step 1) with aqueous citric acid solution for beating to obtain lotus root pulp;

[0028] 3) vacuum microwave the described lotus root slurry obtained in step 2) for 4 to 8 minutes to obtain hot lotus root slurry;

[0029] 4) mixing the hot lotus root slurry obtained in step 3) with amylase, and performing the first ultrasonic treatment for 3 to 5 minutes to obtain the first enzymatic hydrolyzed lotus root slurry;

[0030] 5) Mix the first enzymatically hydrolyzed lotus root slurry obtained in step 4) with pectinase and cellulase, and perform the second ultrasonic treatment for 60-80 minutes to obtain the second enz...

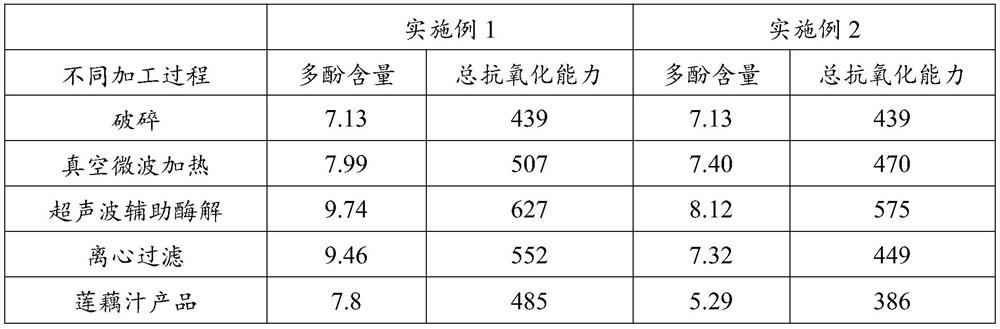

Embodiment 1

[0054] Using fresh beauty red lotus root as raw material, washing to remove sludge and impurities, slicing the washed lotus root (including lotus root skin and lotus joint), and soaking in 0.15% citric acid solution;

[0055] Add 0.07% citric acid solution to the lotus root slices according to the material-to-liquid ratio of 1:3, and beat;

[0056] Put lotus root pulp into constant temperature vacuum microwave heating equipment, set vacuum degree 0.09MPa, microwave power 3W / g, heating time 6min;

[0057] The lotus root slurry heated by vacuum microwave was immediately placed in an ultrasonic cleaning machine, and 0.2% (V:V) liquid α-high temperature amylase (enzyme activity 40000U / mL) was added to the lotus root slurry, and the ultrasonic temperature was set at 80°C. Power 200W, ultrasonic time 4min;

[0058] When the temperature of lotus root pulp drops to 55°C, add 0.1% (V:V) pectinase (enzyme activity 60000U / mL), 0.15% (W:V) cellulase (enzyme activity 7000U / g), set Ultras...

Embodiment 2

[0064] Using fresh lotus root as raw material, washing and removing sludge and impurities, slicing the washed lotus root (including lotus root skin and lotus joint), and soaking in 0.15% citric acid solution;

[0065] Add 0.08% citric acid solution to the lotus root slices according to the material-to-liquid ratio of 1:3 and beat;

[0066] Put the lotus root pulp into the vacuum microwave heating equipment, set the vacuum degree to 0.08MPa, the microwave power to 2W / g, and the heating time to 8min;

[0067] The lotus root slurry heated by vacuum microwave was immediately placed in an ultrasonic cleaning machine, and 0.15% (V:V) liquid α-high temperature amylase (enzyme activity 40000U / mL) was added to the lotus root slurry, and the ultrasonic temperature was set at 90°C. Power 300W, ultrasonic time 3min;

[0068] When the temperature of lotus root pulp drops to 50°C, add 0.07% (V:V) pectinase (enzyme activity 60000U / mL), 0.1% (W:V) cellulase (enzyme activity 7000U / g), set Ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com