Multi-layer flexible damping sandwich material and preparation method thereof

A sandwich material and flexible buffer technology, applied in the field of textile composite materials, can solve the problems of soft polyurethane volume limitation, reduced shear thickening effect, inability to achieve protective effect, etc., to improve shear toughness and resistance to sharp objects tearing. cracking ability, excellent statics and shape retention properties, and excellent energy absorption and buffering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention simultaneously provides a kind of preparation method (abbreviation method) of multi-layer flexible cushioning sandwich material, it is characterized in that this method comprises the following steps:

[0044] A. Preparation of shear thickening fluid:

[0045] (1) Calculate the total mass of the shear thickening fluid according to the volume of the buffer zone;

[0046] (2) drying the nano-silica with a quality of 12-45% of the total mass of the shear thickening fluid in a vacuum drying oven to remove moisture;

[0047] (3) Weigh polyethylene glycol, and slowly add nano-silica to polyethylene glycol at a stirring speed of 300-500r / min; specifically, the nano-silica to be added is completely dispersed in polyethylene glycol , and then continue nano-silica until the addition is complete; the entire stirring time is 5h-6h;

[0048] (4) In order to ensure that the shear thickening fluid can be dispersed evenly, the prepared shear thickening fluid is u...

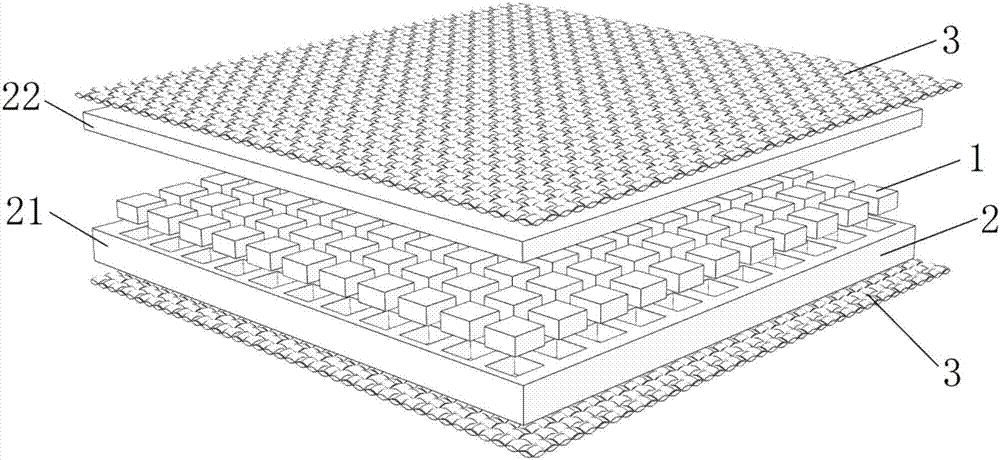

Embodiment 1

[0058] Multi-layer flexible cushioning sandwich material: the volume of the cushioning area accounts for 13% of the entire material volume; the specification of the structural support layer 2 is 350mm×330mm×30mm; the buffer unit 1 is rectangular, the size is 20mm×20mm, and the depth is 10mm. The interval between the units 1 is 10mm; the covering protection layer 3 is made of fabric and placed on the upper and lower sides of the structural support layer. The particle size of nano-silica is 12nm; the foaming density is 0.18g / cm 2 , The overall thickness of the material is 30mm.

[0059] The preparation method of the multi-layer flexible cushioning sandwich material, the specific steps are as follows:

[0060] A. Preparation of shear thickening fluid:

[0061] (1) Calculate the total mass of the shear thickening fluid according to the volume of the buffer zone to be 500g;

[0062] (2) 90g of nano silicon dioxide is dried in a vacuum oven to remove moisture;

[0063] (3) Take ...

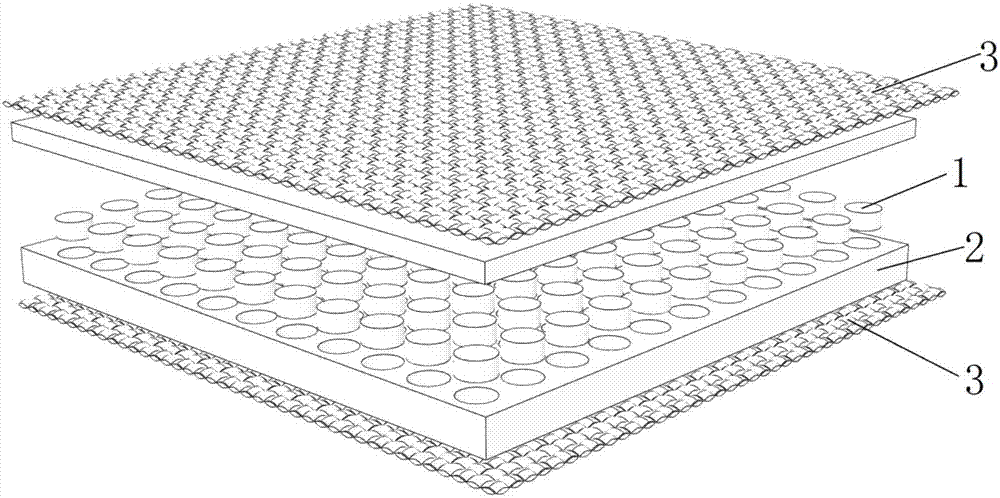

Embodiment 2

[0071] Multi-layer flexible cushioning sandwich material: the volume of the cushioning area accounts for 15% of the entire material volume; the specification of the structural support layer 2 is 350mm×330mm×30mm; the cushioning unit 1 is circular, with a diameter of 20mm and a depth of 10mm. 1 with an interval of 10 mm; the covering protection layer 3 is made of fabric and placed on the upper and lower sides of the structural support layer. The particle size of nano-silica is 12nm; the foaming density is 0.18g / cm 2 , The overall thickness of the material is 30mm.

[0072] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com