Automatic polishing wire of precision ball

An automatic polishing and steel ball technology, applied in grinding/polishing equipment, machine tools for surface polishing, cleaning methods using liquids, etc., can solve the problems of insufficient cleanliness, high processing costs, and high noise, and achieve Achieve diversification, satisfy cleanliness, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

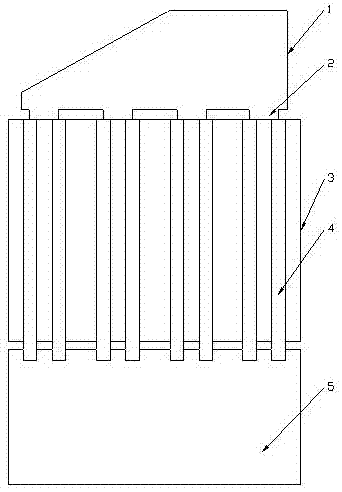

[0030] like figure 1 , figure 2 A precision steel ball automatic polishing line is shown, including

[0031] A cleaning unit, the cleaning unit includes a cleaning cylinder 102, the cleaning cylinder 102 is a hollow cylinder structure with an upper end opening, a cleaning water outlet 101 is provided at the bottom of the cleaning cylinder 102, and the cleaning cylinder 102 can be poured The mechanism is driven to swing.

[0032] The dumping mechanism is specifically: both ends of the cleaning cylinder 102 are fixed on a cylinder support through bearing seats, and the cleaning cylinder 102 can be pushed by the drive cylinder to swing along the connection point between the cleaning cylinder 102 and the cylinder support. By setting the dumping mechanism, the entire cleanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com