Preparation of NiWAlZr hydrotalcite-like catalyst and application of catalyst in hydrodesulfurization

A hydrodesulfurization and hydrotalcite-like technology, applied in the direction of heterogeneous catalyst chemical elements, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of strong interaction and catalyst specific surface area Low-level problems, to achieve the effect of high dispersion of active components, excellent hydrodesulfurization performance, and easy reduction vulcanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

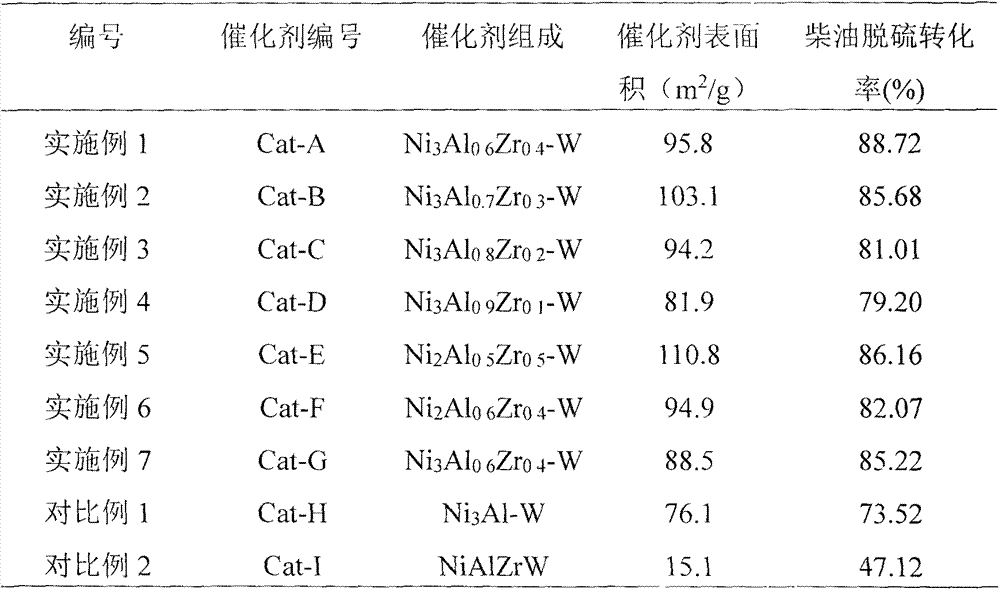

Examples

Embodiment 1

[0029] According to the ratio of Ni / Al / Zr=3 / 0.6 / 0.4, weigh Ni(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O, ZrO(NO 3 ) 2 2H 2 Dissolve O in 100ml of boiled deionized water to prepare a mixed salt solution; in addition, dissolve NaOH in 100ml of deionized water to prepare a 1mol / L alkaline solution. Pour the mixed salt solution into the flask, and drop in the NaOH solution at a rate of 4-6 s / drop, stop when the pH of the solution is 8, and continue stirring for 60 min. Subsequently, hydrothermal crystallization was carried out at 100°C for 12 hours, and the obtained precipitate was filtered and washed to neutrality with boiled deionized water, and vacuum-dried at 80°C for 6 hours to obtain nitrate-type nickel aluminum zirconium hydrotalcite (Ni 3 al 0.6 Zr 0 4 -NO 3 -LDH).

[0030] Take Ni 3 al 0 6 Zr 0 4 -NO 3 -LDHs, Na 2 WO 4 Prepare a suspension with ethylene glycol and pour it into a flask with 2% HNO 3 Adjust the pH of the solution to 6.5, exchange it at 120°C f...

Embodiment 2

[0033] According to the ratio of Ni / Al / Zr=3 / 0.7 / 0.3, weigh Ni(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O, ZrO(NO 3 ) 2 2H 2 Dissolve O in 100ml of boiled deionized water to prepare a mixed salt solution; in addition, dissolve NaOH in 100ml of deionized water to prepare a 1mol / L alkaline solution. Pour the mixed salt solution into the flask, and drop in the NaOH solution at a rate of 4-6 s / drop, stop when the pH of the solution is 8, and continue stirring for 60 min. Subsequently, it was hydrothermally crystallized at 120°C for 12 hours, and the obtained precipitate was filtered and washed to neutrality with boiled deionized water, and dried in vacuum at 80°C for 6 hours to obtain nitrate-type nickel aluminum zirconium hydrotalcite (Ni 3 al 0 7 Zr 0 3 -NO 3 -LDH).

[0034] Take Ni 3 al 0 7 Zr 0 3 -NO 3 -LDHs, Na 2 WO 4 Prepare a suspension with ethylene glycol and pour it into a flask with 2% HNO 3 Adjust the pH of the solution to 6, exchange it at 120°C for 10h, f...

Embodiment 3

[0037] According to the ratio of Ni / Al / Zr=3 / 0.8 / 0.2, weigh Ni(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O, ZrO(NO 3 ) 2 2H 2 Dissolve O in 100ml of boiled deionized water to prepare a mixed salt solution; in addition, dissolve NaOH in 100ml of deionized water to prepare a 1mol / L alkaline solution. Pour the mixed salt solution into the flask, and drop in the NaOH solution at a rate of 4-6 s / drop, stop when the pH of the solution is 9, and continue stirring for 60 min. Subsequently, hydrothermal crystallization at 80°C for 10h, the obtained precipitate was filtered and washed to neutrality with boiled deionized water, and vacuum-dried at 80°C for 6h to obtain nitrate-type nickel aluminum zirconium hydrotalcite (Ni 3 al 0 8 Zr 0 2 -NO 3 -LDH).

[0038] Take Ni 3 al 0.8 Zr 0 2 -NO 3 -LDHs, Na 2 WO 4 Prepare a suspension with ethylene glycol and pour it into a flask with 2% HNO 3 Adjust the pH of the solution to 6.5, exchange it at 100°C for 10h, filter and wash the res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com