Magnesium-air battery hydrogel electrolyte and preparation method thereof and magnesium-air battery

An air battery and hydrogel technology, applied in non-aqueous electrolyte batteries, electrolyte battery manufacturing, secondary batteries, etc., can solve problems such as corrosion and environmental pollution of aqueous solutions, and achieve discharge requirements, long discharge time, and water absorption. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

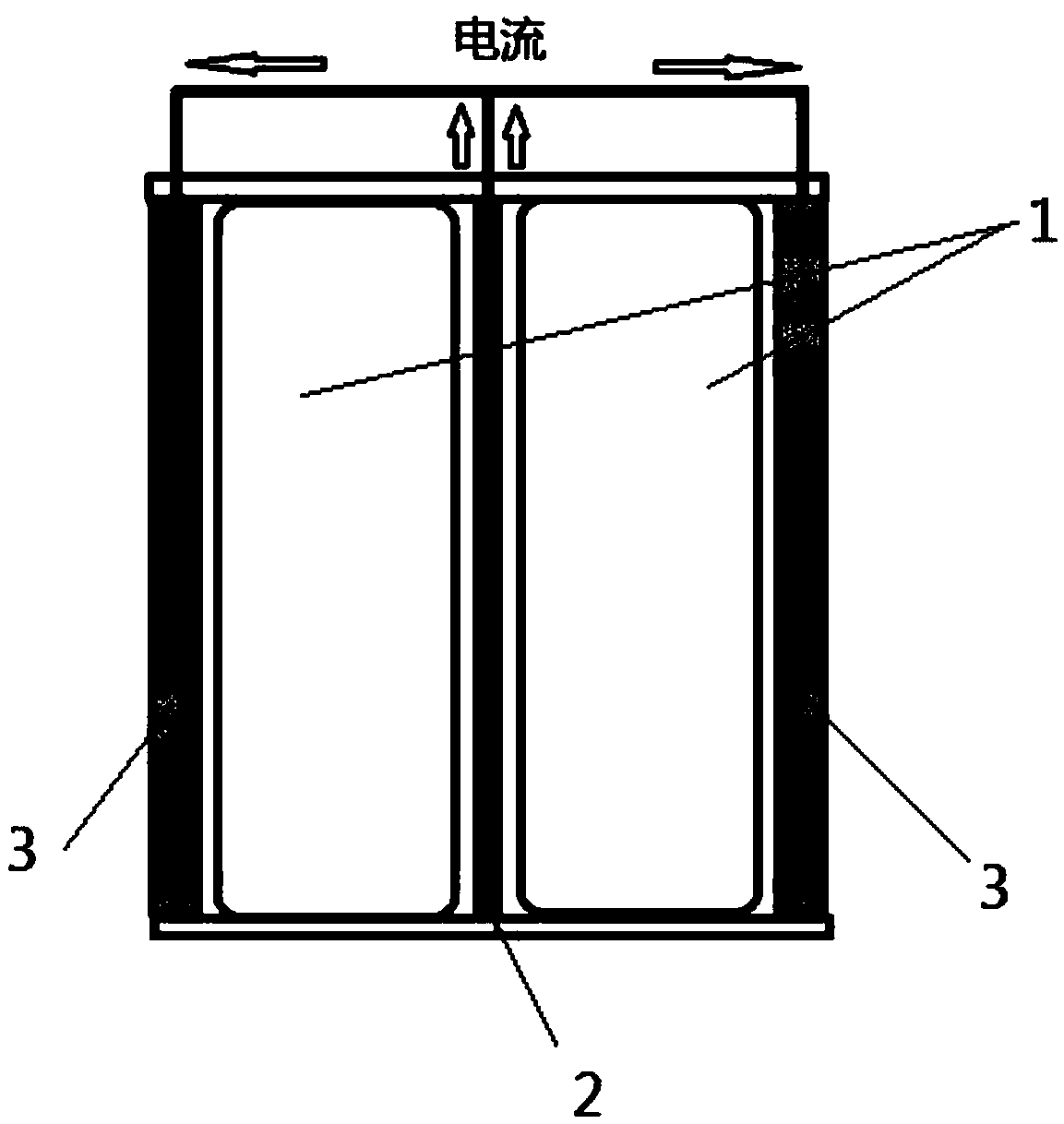

Image

Examples

Embodiment 1

[0034] A magnesium alloy-air battery, the electrolyte of which is a hydrogel electrolyte for a magnesium-air battery. The hydrogel electrolyte for a magnesium-air battery uses a blend of polyacrylamide and acrylic acid-acrylamide as a high water-absorbing polymer material. The specific preparation steps of the battery hydrogel electrolyte are as follows:

[0035] S1: The weight of the hydrogel electrolyte set for the magnesium-air battery is 100kg, and the weight of the superabsorbent polymer material polyacrylamide and acrylic acid-acrylic acid amide is weighed according to the ratio of 5% of the weight of the hydrogel electrolyte set for the magnesium-air battery. Blend (the mass ratio of polyacrylamide and acrylic acid-acrylamide is 1:1), the blend of polyacrylamide and acrylic acid-acrylamide is ground into a powder with a particle size of 75 μm~250 μm;

[0036] S2: Wrap the weighed polyacrylamide and acrylic acid-acrylamide blend with dust-free paper, and the mass ratio o...

Embodiment 2

[0041] A magnesium alloy-air battery, the electrolyte of which is a hydrogel electrolyte for a magnesium-air battery. The hydrogel electrolyte for a magnesium-air battery uses polyacrylamide as a high water-absorbing polymer material. The specific preparation steps of the hydrogel electrolyte for a magnesium-air battery are as follows :

[0042] S1: Magnesium alloy air battery sets the weight of the hydrogel electrolyte to 100kg, weighs polyacrylamide, a high water absorption polymer material, according to the proportion of 10% of the weight of the hydrogel electrolyte set by the magnesium air battery, and grinds the polyacrylamide Form into a powder with a particle size of 100μm~150μm;

[0043] S2: Wrap the weighed polyacrylamide with dust-free paper, and the mass ratio of dust-free paper to polyacrylamide is 1:1;

[0044] S3: Place the coated polyacrylamide in a mold made of plexiglass according to the dimensions of the hydrogel electrolyte set by the magnesium alloy air ba...

Embodiment 3

[0048] A magnesium alloy-air battery, the electrolyte of which is a hydrogel electrolyte for a magnesium-air battery. The hydrogel electrolyte for a magnesium-air battery uses polyacrylamide as a high water-absorbing polymer material. The specific preparation steps of the hydrogel electrolyte for a magnesium-air battery are as follows :

[0049] S1: Magnesium alloy air battery sets the weight of the hydrogel electrolyte to 100kg, weighs polyacrylamide, a high water absorption polymer material, according to the proportion of 10% of the weight of the hydrogel electrolyte set by the magnesium air battery, and grinds the polyacrylamide Form into a powder with a particle size of 100μm~150μm;

[0050] S2: Wrap the weighed polyacrylamide with dust-free paper, and the mass ratio of dust-free paper to polyacrylamide is 1:1;

[0051] S3: Place the coated polyacrylamide in a mold made of plexiglass according to the dimensions of the hydrogel electrolyte set by the magnesium alloy-air ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com