Titanium powder surfactant and using method thereof

A surface activator and activator technology, applied in liquid chemical plating, metal material coating process, coating, etc., can solve the problems of difficult removal of oxide film and lack of mature experience, etc., and achieve stable activation state and good activation effect , to ensure the effect of activation and activity stability control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

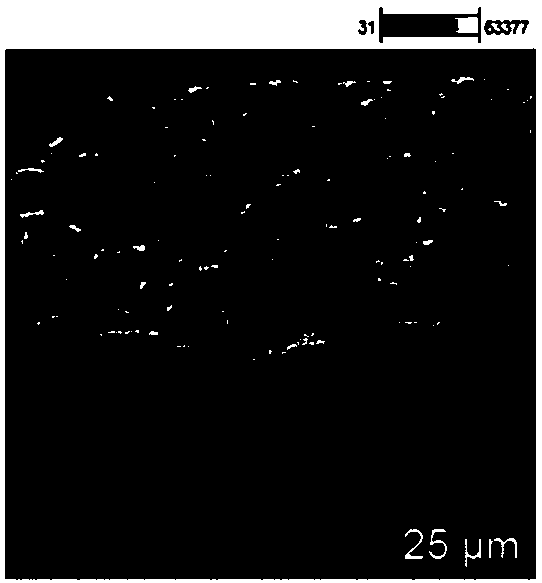

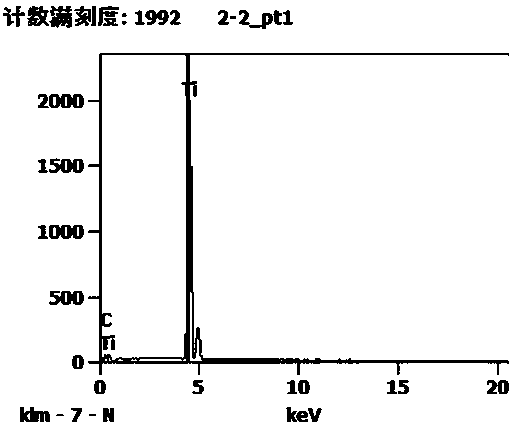

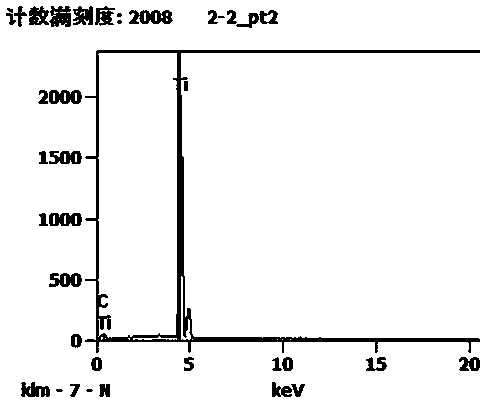

Image

Examples

Embodiment 1

[0029] Components and mass percentages thereof of the titanium powder surfactant described in this example are:

[0030] Ammonium bifluoride 8%

[0032] Polyethylene glycol 4000 6%

[0033] Nickel Sulfamate 5%

[0034] Oxalic acid 5%

[0035] OP-10 10%

[0036] Sodium hypophosphite 2%

[0037] Industrial concentrated sulfuric acid 5%

[0038] water balance

[0039] The components of the above-mentioned titanium powder surfactant are all industrial-grade chemical raw materials. After weighing according to the above-mentioned mass percentage, first add water and industrial concentrated sulfuric acid to the container, and then add ammonium bifluoride, zinc sulfate, oxalic acid, nickel sulfamate , polyethylene glycol, OP-10, stir evenly and the preparation is completed.

[0040] The titanium powder surface activator described in this example is used for the titanium powder activation of the mechanical titanium plating process; the workpiece to be p...

Embodiment 2

[0046] Components and mass percentages thereof of the titanium powder surfactant described in this example are:

[0047] Ammonium bifluoride 20%

[0049] Polyethylene glycol 8000 15%

[0050] Nickel Sulfamate 3%

[0051]TX-10 3%

[0052] Oxalic acid 5%

[0053] Sodium hypophosphite 5%

[0054] Hydrofluoric acid 0.5%

[0055] water balance

[0056] The components of the above-mentioned titanium powder surfactant are all industrial-grade chemical raw materials. After weighing according to the above-mentioned mass percentage, first add water and hydrofluoric acid to the container, and then add ammonium bifluoride, zinc sulfate, oxalic acid, nickel sulfamate , Sodium Hypophosphite, Polyethylene Glycol, TX-10, stir evenly to complete the preparation.

[0057] The titanium powder surfactant described in this example is used for the activation of titanium powder in the mechanical titanium plating process. The workpiece to be plated is a flat gasket ...

Embodiment 3

[0064] Components and mass percentages thereof of the titanium powder surfactant described in this example are:

[0065] Ammonium bifluoride 15%

[0066] Zinc sulfate 8%

[0067] Polyethylene glycol 4000 10%

[0068] Nickel Sulfamate 8%

[0069] OP-10 10%

[0070] Oxalic acid 8%

[0071] Sodium hypophosphite 3%

[0072] Industrial concentrated sulfuric acid 2%

[0073] water balance

[0074] The components of the above-mentioned titanium powder surfactant are all industrial-grade chemical raw materials. After weighing according to the above-mentioned mass percentage, first add water and industrial concentrated sulfuric acid to the container, and then add ammonium bifluoride, zinc sulfate, oxalic acid, nickel sulfamate , sodium hypophosphite, polyethylene glycol, OP-10, stir evenly and the preparation is complete.

[0075] The titanium powder surfactant described in this example is used for the activation of titanium powder in the mechanical titanium plating process. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com