Hydrogen storage fuel and preparation method thereof

A fuel and hydrogen storage technology, applied in the field of electrochemistry, can solve the problems of hydrogen storage fuel reaction kinetics, slow and high temperature sintering, etc. at the same time, and achieve the effects of improving the chemical reaction rate, alleviating easy sintering, and improving the charge and discharge capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

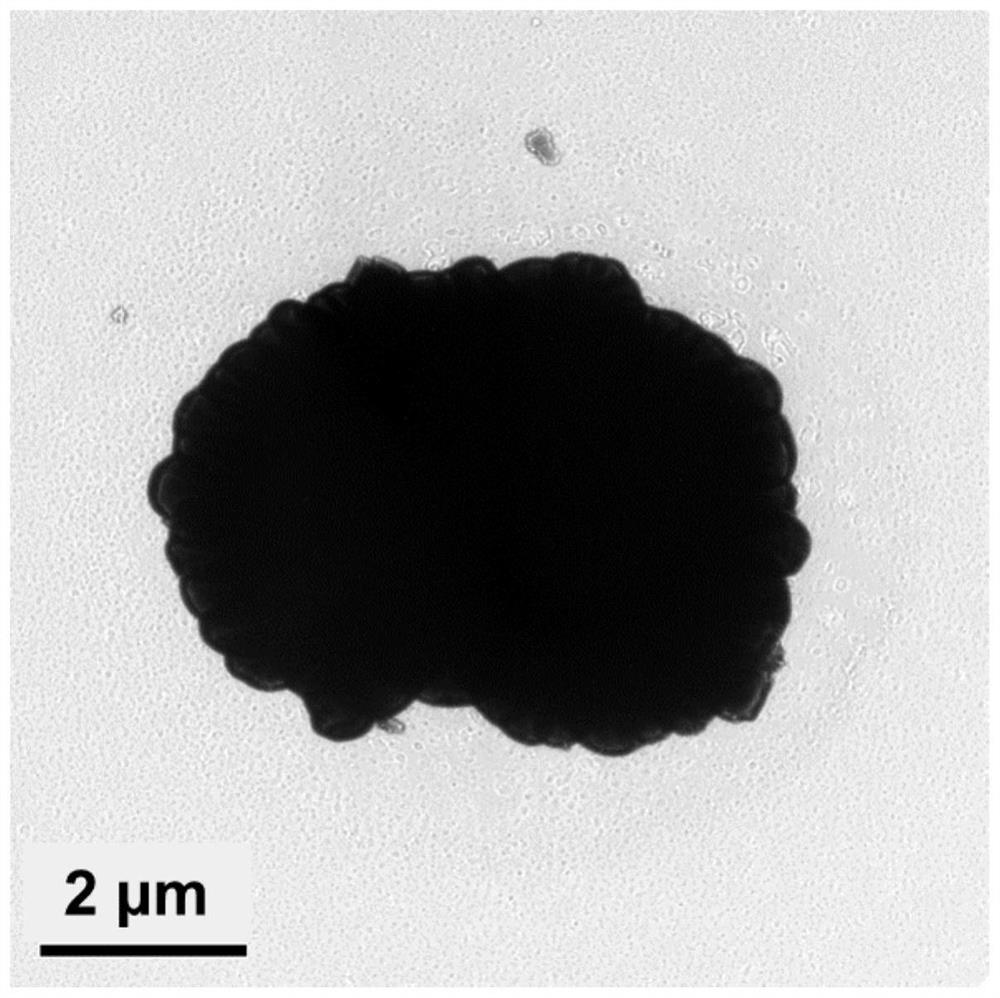

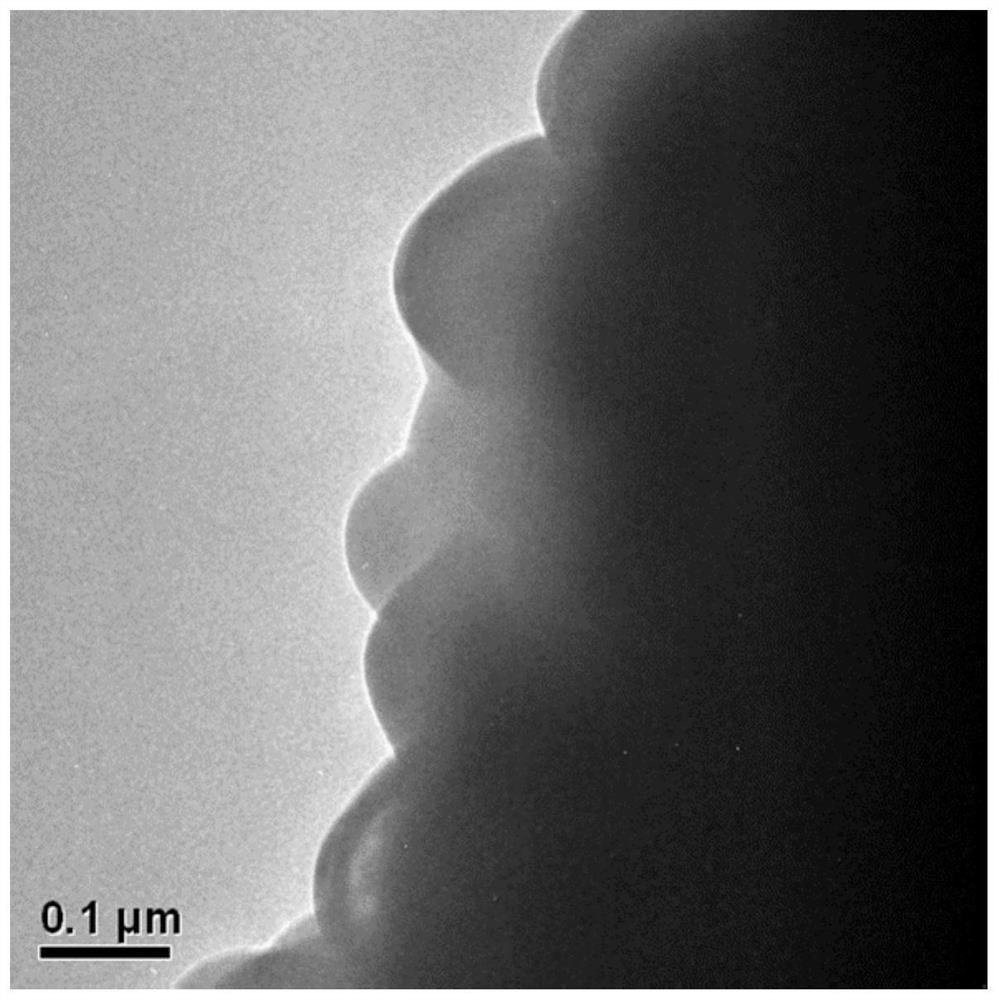

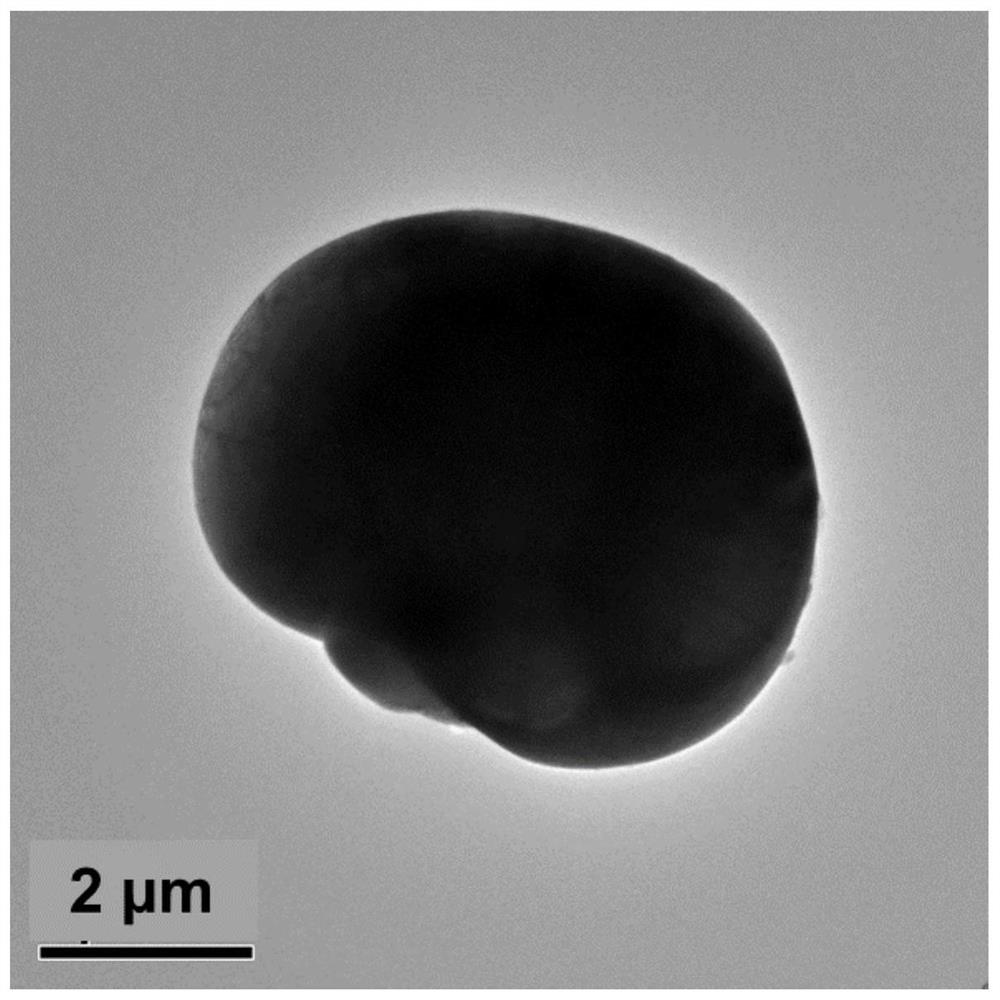

[0032] 50.0g of Fe with a particle size of 5 μm 3 o 4 with 5.0g of Al with a particle size of 200nm 2 o 3 According to the mass ratio of 100:10 rough mix and put into the ball mill tank. 3.2 g of palladium acetate and 7.5 g of glucose were dissolved in 10 mL of water, then added to a ball mill jar, and ball milled at a speed of 400 rpm for 4 hours. The samples were taken out from the ball mill jar, after drying in an oven at 80 °C, at 700 °C with 5 wt% H 2 / Ar atmosphere calcined for 6h to obtain the hydrogen storage fuel, the transmission electron microscope results are as follows figure 1 , 2 shown.

Embodiment 2

[0034] The difference between embodiment 2 and embodiment 1 is that the oxide coating layer used is different. Adopt particle diameter in embodiment 2 and be the ZrO of 200nm 2 As a cladding layer, other processes are consistent with Example 1. 50.0g of Fe with a particle size of 5 μm 3 o 4 With 5.0g of ZrO with a particle size of 200nm 2 According to the mass ratio of 100:10 rough mix and put into the ball mill tank. 3.2 g of palladium acetate and 7.5 g of glucose were dissolved in 10 mL of water, and this solution was also added to the ball mill jar. Ball mill at 400rpm for 4h. The samples were taken out from the ball mill jar, after drying in an oven at 80 °C, at 700 °C with 5 wt% H 2 / Ar atmosphere and calcined for 6h to obtain hydrogen storage fuel.

Embodiment 3

[0036] The difference between embodiment 3 and embodiment 1 is that Al 2 o 3 The particle diameter is 500nm, and other processes are consistent with embodiment 1. In Example 3, the distance between hydrogen storage fuel particles is increased by increasing the particle size of the oxide, so as to provide more sufficient channels for gas phase transmission. The specific process is: 50.0g of Fe with a particle size of 5 μm 3 o 4 with 5.0g of Al with a particle size of 200nm 2 o 3 According to the mass ratio of 100:10 rough mix and put into the ball mill tank. 3.2 g of palladium acetate and 7.5 g of glucose were dissolved in 10 mL of water, and this solution was also added to the ball mill jar. Ball mill at 400rpm for 4h. The samples were taken out from the ball mill jar, after drying in an oven at 80 °C, at 700 °C with 5 wt% H 2 / Ar atmosphere and calcined for 6h to obtain hydrogen storage fuel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com