Method for grain size control and mechanical performance adjustment of GH4698 disc forging

A technology of grain size and forgings, which is applied in the field of grain size control and mechanical property adjustment of GH4698 disk forgings, can solve the problems of high temperature fatigue performance and difficulty in grasping the scale, and achieve the effect of performance matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

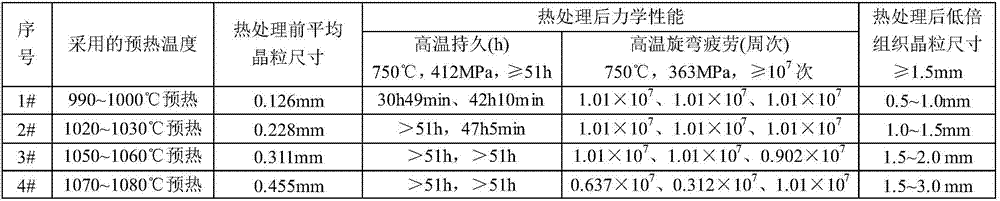

[0020] Select the production and development of a turbine disk forging of a certain type of aircraft below, and describe the process steps of the present invention in detail.

[0021] A method for grain size control and mechanical property adjustment of a GH4698 disc forging is provided, comprising the following steps:

[0022] Step 1. Carry out two fires on the sheathed bar and heat the upsetting cake to obtain a blank, ensuring that the deformation per fire is 25% to 35%;

[0023] Step 2. Carry out one-fire heating die forging on the blank to obtain the forging and air-cool it to ensure that the deformation is 25% to 35%;

[0024] Step 3. Perform the first solid solution treatment on the forging. First, heat the forging to 800°C with a heat preservation coefficient of 0.8min / mm, and then raise the temperature to the preheating temperature at a heating rate of 50-70°C / min with a heat preservation coefficient of 0.8min / mm. mm, then heated up to 1100°C, held for 8 hours, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com