Urban sewage treatment method

A treatment method and technology of urban sewage, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of not being utilized, wasting treatment capacity, wasting water sources, etc., to achieve The effect of improving utilization rate, reducing construction and reducing sewage volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

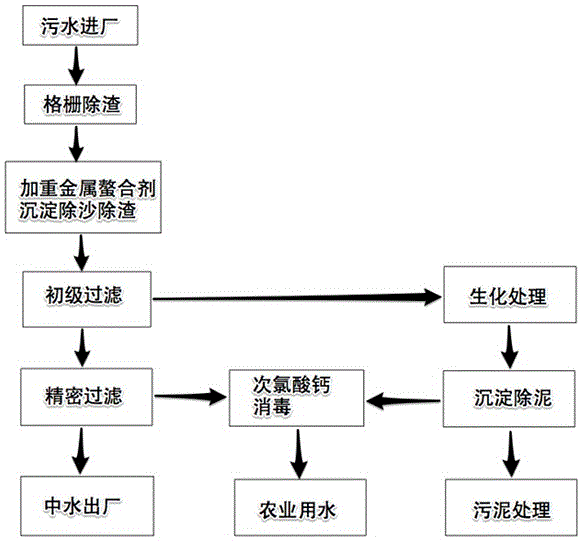

[0033] A kind of concrete steps of the treatment method of urban sewage are as follows:

[0034] Sewage enters the plant → screen slag removal → heavy metal chelating agent sedimentation sand removal slag removal → primary filtration to obtain sewage A and filtered water B containing large particles of dirt. Sewage A undergoes traditional biochemical treatment and then settles and removes mud to obtain filtered Water C and sludge; sludge for sludge treatment;

[0035] Filtered water B is finely filtered to obtain filtered water D and reclaimed water;

[0036] Reclaimed water leaves the factory directly; filtered water D and filtered water C are combined, disinfected with calcium hypochlorite, and shipped as agricultural water;

[0037] Among them, sand filtration equipment and microfiltration equipment are used for primary filtration, and the pore size of microfiltration is 0.1 micron; cross-flow filtration is used for primary filtration; hollow fiber ultrafiltration membrane...

Embodiment 2

[0043] A kind of concrete steps of the treatment method of urban sewage are as follows:

[0044] Sewage enters the plant → screen slag removal → heavy metal chelating agent sedimentation sand removal slag removal → primary filtration to obtain sewage A and filtered water B containing large particles of dirt. Sewage A undergoes traditional biochemical treatment and then settles and removes mud to obtain filtered Water C and sludge; sludge for sludge treatment;

[0045] Filtered water B is finely filtered to obtain filtered water D and reclaimed water;

[0046] Reclaimed water leaves the factory directly; filtered water D and filtered water C are combined, disinfected with calcium hypochlorite, and shipped as agricultural water;

[0047] Among them, sand filtration equipment and microfiltration equipment are used for primary filtration, and the pore size of microfiltration is 0.1 micron; cross-flow filtration is used for primary filtration; hollow fiber ultrafiltration membrane...

Embodiment 3

[0053] A kind of concrete steps of the treatment method of urban sewage are as follows:

[0054] Sewage enters the plant → screen slag removal → heavy metal chelating agent sedimentation sand removal slag removal → primary filtration to obtain sewage A and filtered water B containing large particles of dirt. Sewage A undergoes traditional biochemical treatment and then settles and removes mud to obtain filtered Water C and sludge; sludge for sludge treatment;

[0055] Filtered water B is finely filtered to obtain filtered water D and reclaimed water;

[0056] Reclaimed water leaves the factory directly; filtered water D and filtered water C are combined, disinfected with calcium hypochlorite, and shipped as agricultural water;

[0057] Among them, sand filtration equipment and microfiltration equipment are used for primary filtration, and the pore size of microfiltration is 0.1 micron; cross-flow filtration is used for primary filtration; hollow fiber ultrafiltration membrane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com