Wafer, wafer detection system and wafer detection method

A detection method and detection system technology, applied in the direction of semiconductor/solid-state device testing/measurement, single semiconductor device testing, electrical components, etc., can solve problems such as time-consuming, accidental damage of micro light-emitting diodes, etc., to speed up and improve detection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The aforementioned and other technical contents, features and effects of the present application will be clearly presented in the following detailed description of a preferred embodiment with reference to the accompanying drawings. The directional terms mentioned in the following embodiments, such as: up, down, left, right, front or back, etc., are only referring to the directions of the drawings. Accordingly, the directional terms used are for illustration and not for limitation of the application.

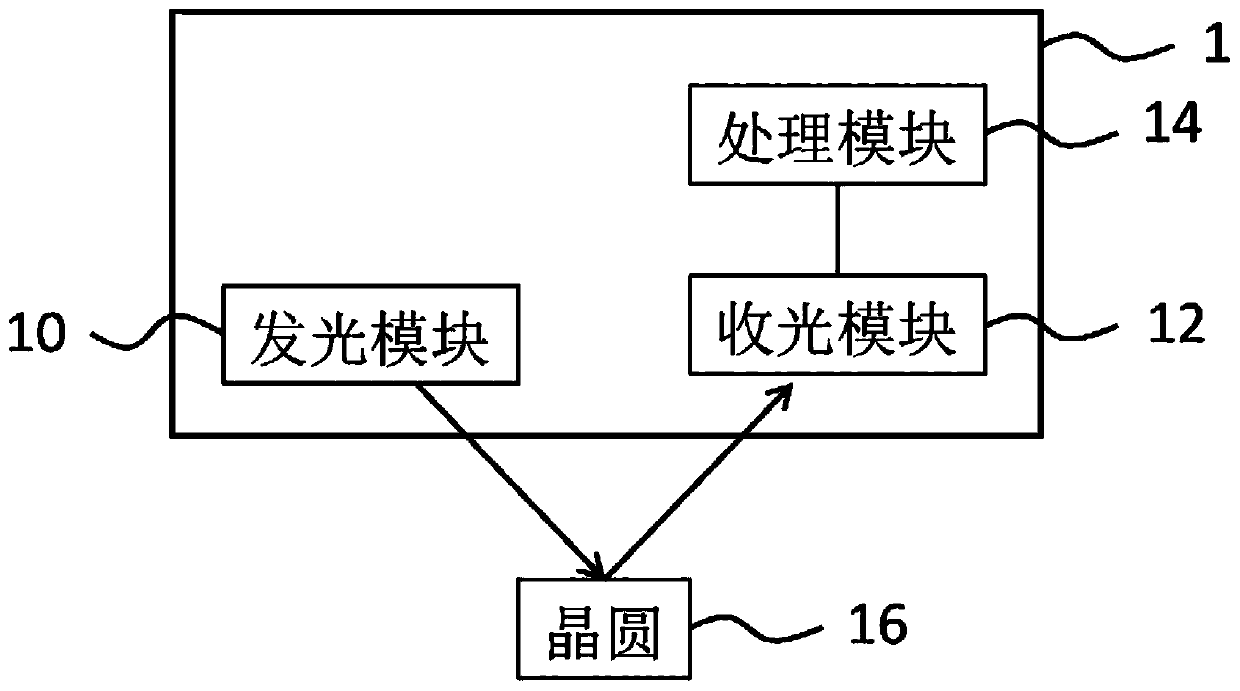

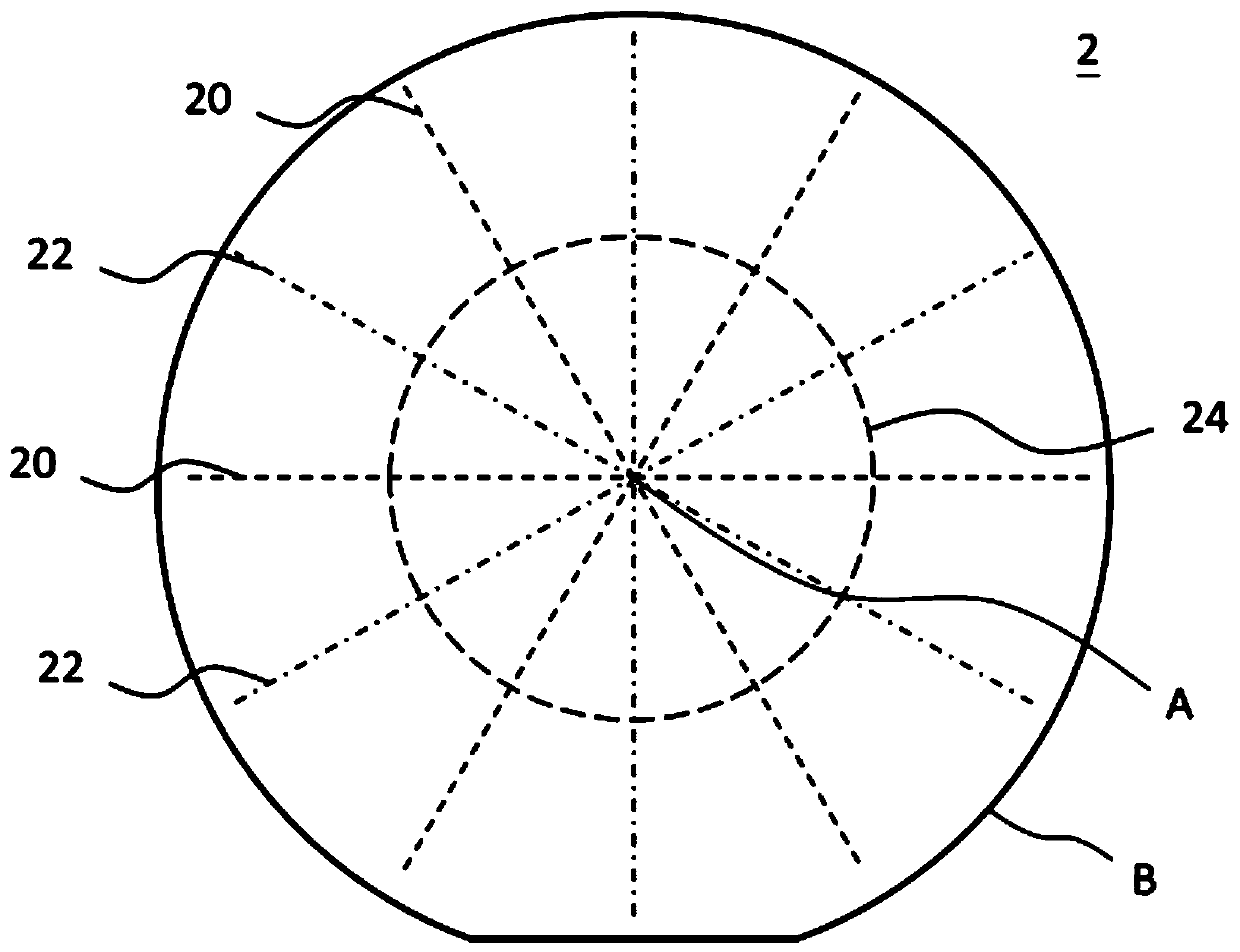

[0032] see Figure 1A and Figure 1B , Figure 1A is a functional block diagram illustrating a wafer inspection system according to an embodiment of the present application, Figure 1B is a schematic diagram illustrating the structure of a wafer according to an embodiment of the present application. As shown in the figure, the wafer inspection system 1 disclosed in this embodiment can be used to inspect the quality of a wafer 16 , and the wafer inspection system 1 can in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com