A production process of qt500-12 ductile iron casting

A technology of ductile iron and production process, which is applied in the field of production process of QT500-12 ductile iron castings, can solve the problems of local function deterioration of ductile iron castings, deterioration of spheroidizing effect of enriched parts, obvious cutting effect of metal matrix, etc., and achieve reduction Cutting, stable absorption rate, good absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

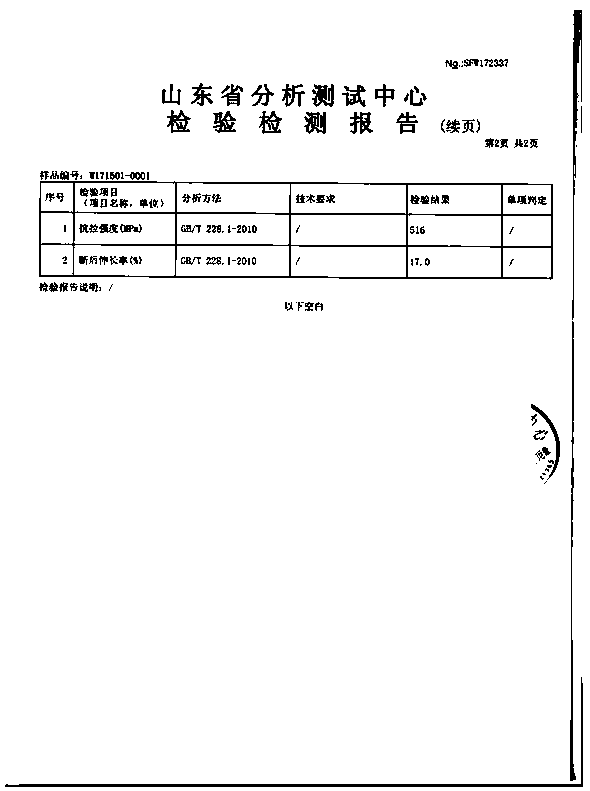

Image

Examples

Embodiment 1

[0023] A production process of QT500-12 ductile iron castings is characterized in that it comprises the following steps:

[0024] A, selection of raw materials: The raw materials for the preparation of QT500-12 ductile iron castings are the raw materials in the following parts by weight ratio, 60 parts of scrap steel, 40 parts of returned furnace charge, 2.5 parts of recarburizer, 0.4 part of 75# ferrosilicon, copper 0.6 part, 1.2 parts of nodulizer, 0.8 part of 75# ferrosilicon inoculant, 0.4 part of silicon strontium inoculant; Described steel scrap is Q235 low manganese steel scrap, and described recarburizer is semi-graphite powdery recarburizer, described Copper is electrolytic copper with a mass content of 99.99%, the nodulizer is a yttrium-based heavy rare earth magnesium composite nodulizer, the particle size of the 75# ferrosilicon inoculant is 10mm, and the particle size of the silicon strontium inoculant is 1mm;

[0025] B. Weigh Q235 low-manganese steel scrap, ret...

Embodiment 2

[0032] A production process of QT500-12 ductile iron castings is characterized in that it comprises the following steps:

[0033] A, selection of raw materials: the raw materials for the preparation of QT500-12 ductile iron castings are the following raw materials in parts by weight ratio, 70 parts of steel scrap, 30 parts of returned furnace charge, 3 parts of recarburizer, 0.8 part of 75# ferrosilicon, copper 0.5 part, 1.0 part of nodulizer, 1.0 part of 75# ferrosilicon inoculant, 0.3 part of silicon strontium inoculant; Described steel scrap is Q235 low manganese steel scrap, and described recarburizer is semi-graphite powdery recarburizer, described Copper is electrolytic copper with a mass content of 99.99%, the nodulizer is a yttrium-based heavy rare earth magnesium composite nodulizer, the particle size of the 75# ferrosilicon inoculant is 12mm, and the particle size of the silicon strontium inoculant is 2mm;

[0034] B. Weigh Q235 low-manganese steel scrap, return mat...

Embodiment 3

[0041] A production process of QT500-12 ductile iron castings is characterized in that it comprises the following steps:

[0042] A, selection of raw materials: the raw materials for the preparation of QT500-12 ductile iron castings are the raw materials in the following proportions by weight, 80 parts of steel scrap, 20 parts of returned furnace charge, 3.5 parts of recarburizer, 1.0 part of 75# ferrosilicon, copper 0.3 part, 1.0 part of nodulizer, 1.2 part of 75# ferrosilicon inoculant, 0.2 part of silicon strontium inoculant; Described steel scrap is Q235 low manganese steel scrap, and described recarburizer is semi-graphite powdery recarburizer, described Copper is electrolytic copper with a mass content of 99.99%, the nodulizer is a yttrium-based heavy rare earth magnesium composite nodulizer, the particle size of the 75# ferrosilicon inoculant is 8 mm, and the particle size of the silicon strontium inoculant is 3mm;

[0043] B. Weigh Q235 low-manganese steel scrap, retu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com