A method for obtaining fine primary α-al equiaxed grains in zinc-aluminum alloys

An equiaxed grain and aluminum alloy technology, applied in the field of alloy materials, can solve the problems of weakened grain refinement effect and limited grain refinement effect of primary α-Al

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

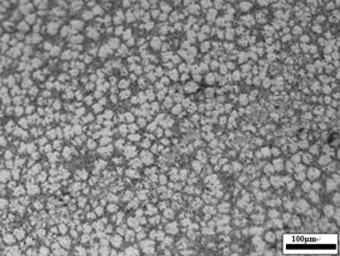

Embodiment 1

[0026] In the Zn-34 wt.%Al alloy (the mass percentage of Zn in the alloy is 66%, the mass percentage of Al is 34%, and the wt.% is omitted below, that is, Zn-34Al) (the liquidus temperature is 530°C) The method for obtaining spherical or polyhedral fine primary α-Al equiaxed grains, the steps are as follows:

[0027] Step S110, preparing Zn-31.9Al-6Ce-0.3Mg master alloy, the steps are as follows:

[0028] Step S111, mixing pure Zn, pure Al, pure Mg and Al-20Ce master alloy to obtain a Zn-Al-Ce-Mg mixed raw material, wherein the mass ratio of Zn and Al in the Zn-Al-Ce-Mg mixed raw material is equal to The mass ratio (66:34) of Zn and Al in Zn-Al alloy is the same.

[0029] Step S112, put the Zn-Al-Ce-Mg mixed raw material in a crucible, heat it to 700-750°C and melt it completely, keep it warm for 15-30 minutes, then stir it fully, pour it into a mold, and cool it to get Zn-31.9 Al-6Ce-0.3Mg master alloy.

[0030] In step S120, a Zn-32Al-6Zr master alloy is prepared accordin...

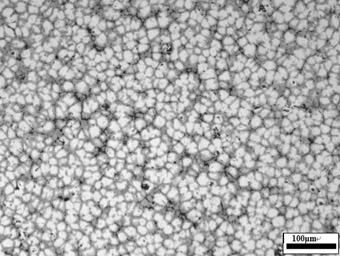

Embodiment 2

[0035] The method for obtaining spherical or polyhedral fine primary α-Al equiaxed grains in Zn-34Al alloy (liquidus temperature is 530°C), the steps are as follows:

[0036] Step S210, preparing Zn-31.9Al-6Ce-0.3Mg master alloy, the preparation steps are the same as the method provided in Example 1, and will not be repeated here.

[0037] In step S220, a Zn-32Al-6Zr master alloy is prepared according to the prior art, which will not be repeated here.

[0038] Step S230, melting the Zn-34Al alloy to 700° C. to obtain a Zn-34Al alloy melt.

[0039] In step S240, simultaneously add the Zn-31.9Al-6Ce-0.3Mg master alloy prepared in step S210 and the Zn-32Al-6Zr master alloy prepared in step S220 into the Zn-34Al alloy melt, and continue to keep warm for 8-20 minutes, fully Stir to make Zr, Ce, and Mg elements evenly distribute in the Zn-34Al alloy melt to obtain the final alloy melt, wherein the contents of Zr, Ce, and Mg elements in the final alloy melt are 0.1wt.%, 0.1wt.%, res...

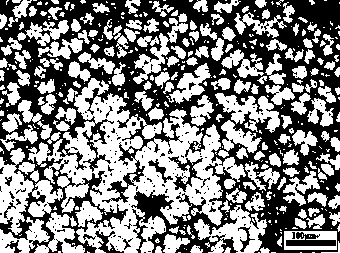

Embodiment 3

[0042]The method for obtaining spherical or polyhedral fine primary α-Al equiaxed grains in Zn-34Al alloy (liquidus temperature is 530°C), the steps are as follows:

[0043] In step S310 , preparing a Zn-31.9Al-6Ce-0.3Mg master alloy, the preparation steps are the same as the method provided in Example 1, and will not be repeated here.

[0044] In step S320, a Zn-32Al-6Zr master alloy is prepared according to the prior art, which will not be repeated here.

[0045] Step S330, melting the Zn-34Al alloy to 700° C. to obtain a Zn-34Al alloy melt.

[0046] In step S340, the Zn-31.9Al-6Ce-0.3Mg master alloy prepared in step S310 and the Zn-32Al-6Zr master alloy prepared in step S320 are simultaneously added to the Zn-34Al alloy melt, and the heat preservation is continued for 8-20 minutes, fully Stir to make the Zr, Ce, and Mg elements evenly distributed in the Zn-34Al alloy melt to obtain the final alloy melt, wherein the contents of Zr, Ce, and Mg elements in the final alloy mel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com