Preparation method of chlorophosphazene

A technology of chlorophosphazene and phosphorus pentachloride, which is applied in the field of preparation of chlorophosphazene, can solve the problems of ammonium chloride easy to absorb moisture, the scale of industrialization, the back suction of the tail gas device, and safety problems affecting the operation of the production device, etc., and achieve good industrialization Application prospects, increased reaction area, and the effect of saving reaction raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

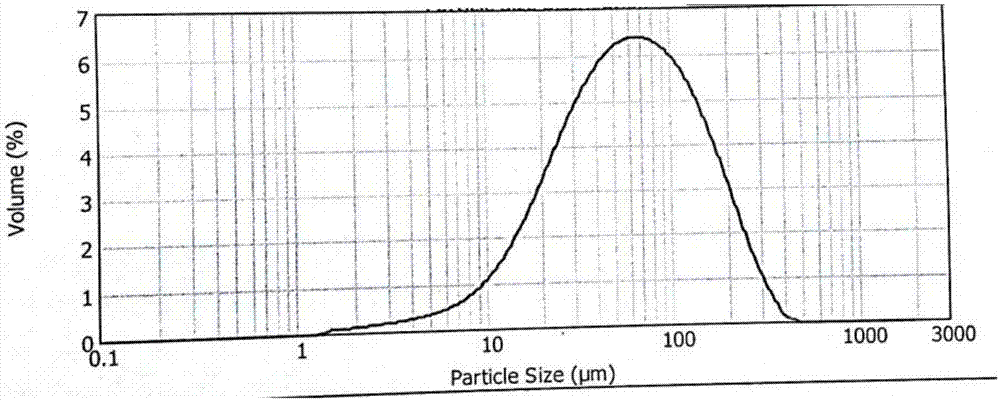

[0033] Add 830 g of chlorobenzene solution containing 208 g of phosphorus pentachloride into a 1 L glass-lined pressure reactor, and add 59 g of ammonium chloride (particle size: 170 μm, see Particle Size figure 1 ), add catalyst ferric chloride zinc oxide compound 2.2g, after the device is installed, connect the lye tail gas recovery device. Turn on stirring and heat. When the temperature rises to 100°C, control the heating rate, continue heating to 130°C, and keep this temperature for 5 hours. After the reaction was completed, the temperature was lowered, and the feed liquid was suction filtered. The organic layer was added with 650ml of water to stir and stratified, and the lower organic layer was added with 500ml of water to stir and stratified. Heptane recrystallization, get white solid 81.2g yield 70% (analysis triploid 72.9%, tetraploid 25.4%) Figure 6 )

Embodiment 2

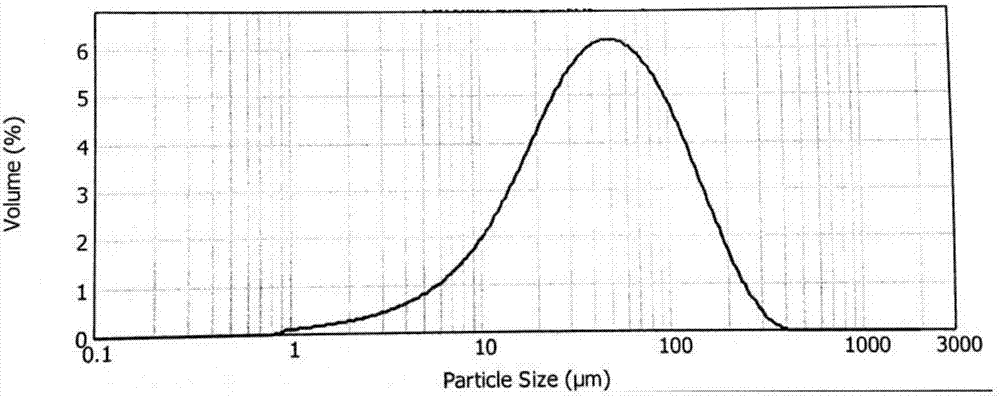

[0035] Add 830 g of chlorobenzene solution containing 208 g of phosphorus pentachloride into a 1L glass-lined pressure reactor, add 59 g of ammonium chloride that was previously dried and pulverized, (see particle size for particle size 133.18 μm) figure 2 ) Add 2.2 g of catalyst ferric chloride zinc oxide compound, install the device and connect the alkali liquor tail gas recovery device. Turn on stirring and heat. When the temperature rises to 100°C, control the heating rate, continue heating to 130°C, and keep this temperature for 5 hours. After the reaction was completed, the temperature was lowered, and the feed liquid was suction filtered. The organic layer was added with 650ml of water to stir and stratified, and the lower organic layer was added with 500ml of water to stir and stratified. Heptane recrystallization, get white solid 92.8g yield 80% (analysis triploid 83.1%, tetraploid 16% HPLC detection chromatographic column: C18, mobile phase: acetonitrile detector w...

Embodiment 3

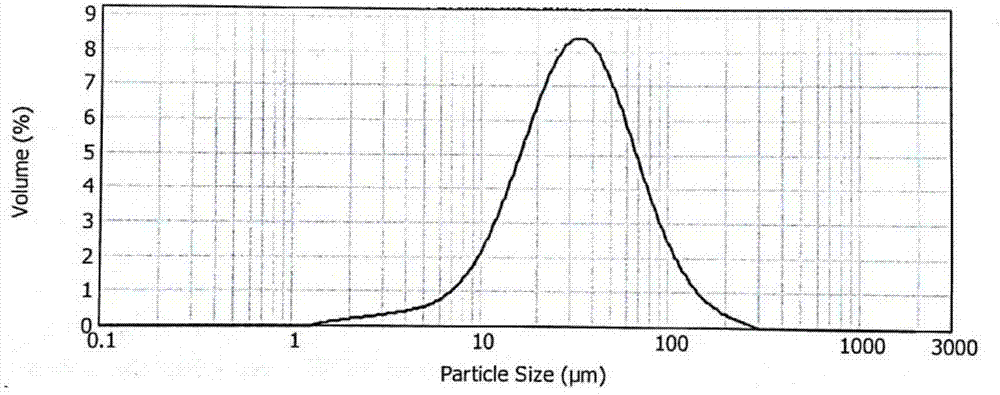

[0037] Add 830 g of chlorobenzene solution of 208 g of phosphorus pentachloride into a 1 L glass-lined pressure reactor, add 14.8 g of crushed and dried ammonium chloride (particle size 81.49 μm, see particle size image 3 ), add catalyst ferric chloride zinc oxide compound 2.2g, after the device is installed and leak test. Turn on the stirring and turn on the heating device. When the temperature rises to 100°C, control the heating rate. When the temperature rises to 130°C, keep it warm for 1 hour. When the pressure in the kettle is 0.1Mpa, the reaction kettle is cooled to 80-90°C and ammonia gas is introduced. The temperature rises and the ammonia is controlled. The speed of the gas keeps the temperature at 2° C. / min, and the feeding of ammonia gas is stopped when the amount of ammonia gas is 68 g. Control the heating rate, when the temperature rises to 130°C, keep it warm for 5 hours, after the reaction is completed, cool down, hydraulically filter the material, wash the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com