Method for preparing ethyl levulinate based on acidic catalyst for catalysis of furfuryl alcohol

A technology of ethyl levulinate and an acidic catalyst is applied in the field of preparation of ethyl levulinate, and can solve the problems of difficult waste liquid treatment to pollute the environment, complicated ethyl levulinate processes, and high catalytic efficiency, and achieves overcoming the problems of the preparation process. Complex, large specific surface area, high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, the present invention: with the mixed solution of water and ethanol as solvent, the method for preparing ethyl levulinate based on acid catalyst catalysis furfuryl alcohol, comprises the following steps:

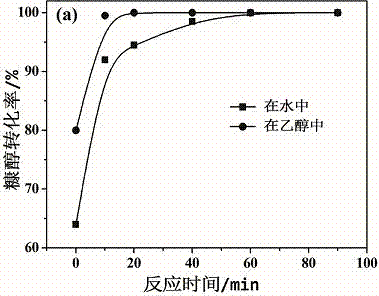

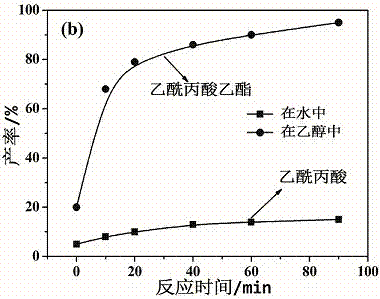

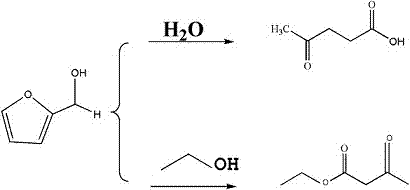

[0026] (1) stirring: the furfuryl alcohol quality is 3g, the acid macroporous resin quality is 5g, the total volume of water and ethanol is 100ml, the volume ratio of ethanol and water is 0.5 / 1, after mixing, stir at room temperature, and the stirring speed is 700rpm, stirring time is 20min; such as figure 1 the formula shown;

[0027] (2) Air exhaust: after the mixture is added to the reactor, high-purity nitrogen is used to remove the air in the autoclave;

[0028] (3) heating: the mixture obtained by stirring is put into the autoclave reactor and heated to 175°C, and the heating rate is 10°C / min;

[0029] (4) sampling: the sample after heating is continued to be incubated at 175 ℃ and reacted, in the insulation process and sampling once every 20min,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com