Composite microbial preparation for assisted treatment of waste cutting fluid, and use method thereof

A technology of compound microorganisms and waste cutting fluid, which is applied in the field of wastewater purification rich in surfactants, can solve the problems of affecting the treatment efficiency and treatment effect of subsequent processes, high treatment costs, and increasing the burden on enterprises, so as to improve oxygen utilization and reduce risk. Small, reduce the effect of toxic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

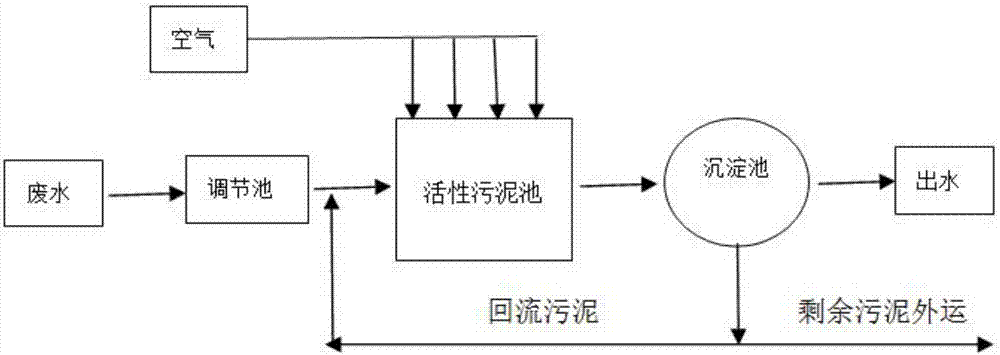

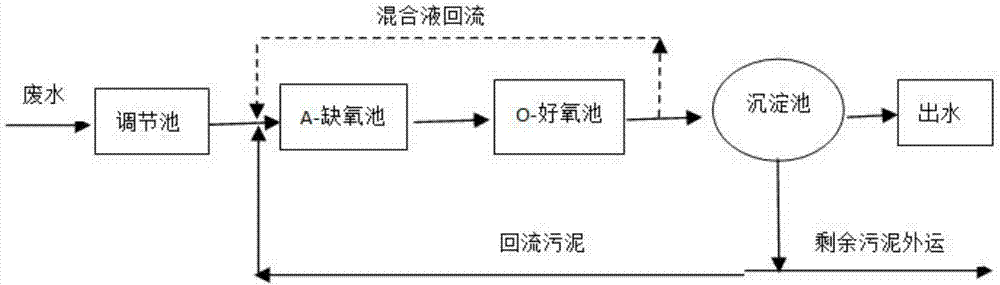

Method used

Image

Examples

Embodiment 1

[0032] A wheel factory uses cutting fluid in the process of metal processing, and regularly discharges cutting waste fluid. After demulsification, flocculation, air flotation and degreasing, the waste fluid is mixed with domestic sewage and enters the biochemical treatment system. The COD of the mixed water is about 1000mg / L After 24 hours of hypoxia and 24 hours of aerobic aeration treatment, the COD of the effluent is 450-500mg / L, and the degradation rate is only about 50%. Often, the COD of the effluent is greater than 500mg / L due to the slightly higher proportion of the waste cutting fluid components in the influent. Exceeding emission standards.

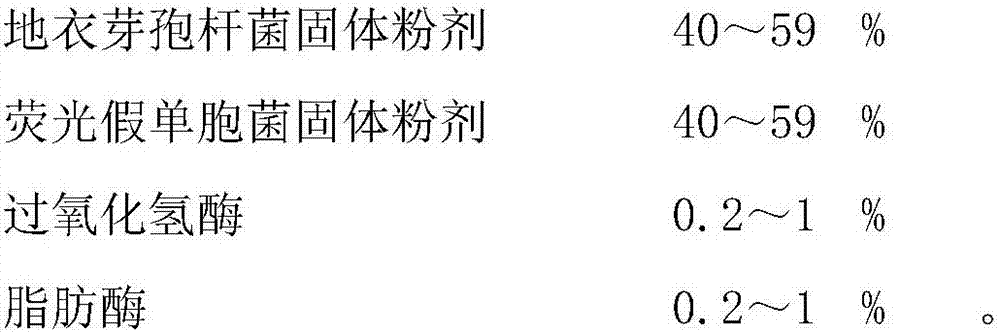

[0033] Use complex microbial preparations to assist the biochemical system to treat wastewater, and the ratio is as follows: Bacillus licheniformis solid powder 59%, Pseudomonas fluorescens solid powder 40%, catalase 0.5%, lipase 0.5%

[0034] The compound microbial preparation is put into the aerobic pool according to the meter...

Embodiment 2

[0039] Another metal processing factory regularly discharges a certain amount of waste cutting fluid, and no domestic sewage is mixed in. After demulsification and flocculation to remove oil, the COD is still around 4000mg / L. The local environmental protection company designed an AO treatment process for the effluent after oil removal. After the completion of the project, the dewatered sludge from the nearby sewage treatment plant was taken for commissioning. After 6 months of commissioning, the effluent was still above 2000mg / L. The reason for the analysis was that the concentration of refractory macromolecular organic matter in the wastewater was high, which had a certain inhibitory effect on the microorganisms in the sludge. The growth condition of activated sludge is poor.

[0040] A complex microbial preparation is used to assist the biochemical system to treat wastewater. The ratio is as follows: Bacillus licheniformis solid powder 40%, Pseudomonas fluorescens solid powde...

Embodiment 3

[0046] There is also a cutting fluid manufacturer that produces a small amount of waste fluid every day, which is currently treated as hazardous waste outsourced. After the waste liquid is demulsified, flocculated and precipitated, the COD of the supernatant reaches 7000-10000mg / L.

[0047] Under laboratory conditions, a 1L plastic measuring cylinder was used to conduct sewage treatment experiments, and simulated domestic sewage with a COD of about 500mg / L was prepared to cultivate activated sludge (the original sludge was taken from the dewatered sludge of a sewage treatment plant). Put the sediment, remove the supernatant and add fresh simulated domestic sewage until the COD degradation rate reaches more than 80% and the SV reaches more than 20%, and then add the double-diluted demulsification and flocculation waste cutting fluid supernatant.

[0048] Add compound microbial preparation, the proportion is as follows: Bacillus licheniformis solid powder 50%, Pseudomonas fluore...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com