Porous material-pored corrugated compound light multifunctional sandwich panel and preparation method

A porous material, multi-functional technology, applied in chemical instruments and methods, lamination, lamination devices, etc., can solve the problems of lack of sound absorption, sound absorption performance and frequency bandwidth to be improved, poor sound insulation performance, etc. To achieve the effect of improving the sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A method for preparing a porous material-perforated corrugated composite lightweight multifunctional sandwich panel, comprising the following steps:

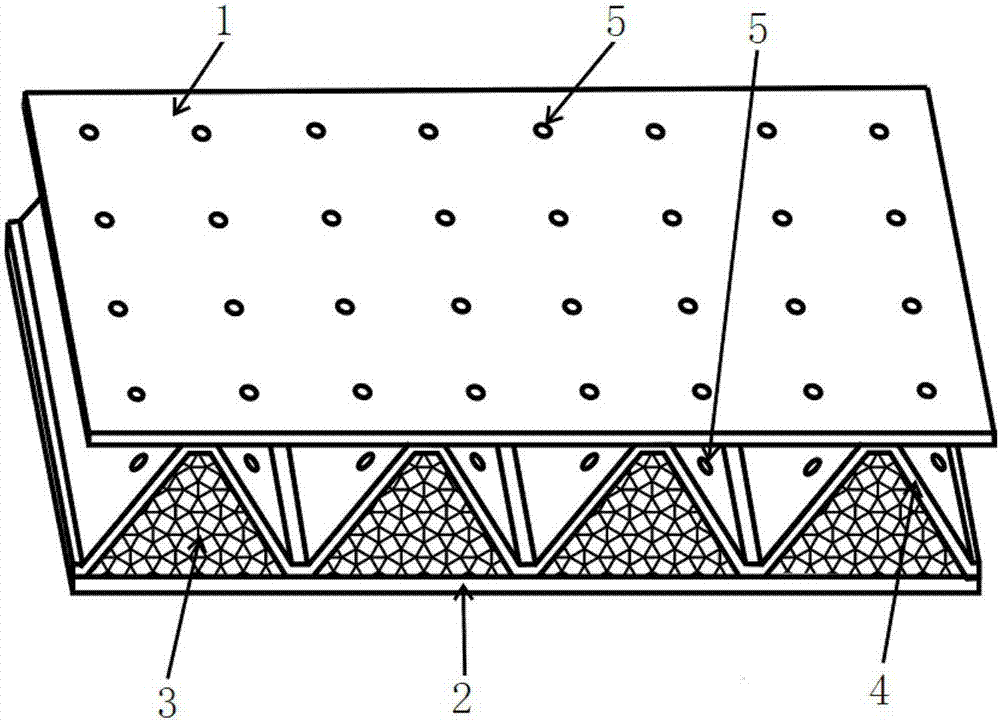

[0036] 1) Using a laser punching machine to punch out evenly distributed circular holes on the thin plate, and then mold and fold the perforated thin plate to prepare a perforated corrugated plate 4;

[0037] 2) stacking and connecting the perforated corrugated sheet 4, the perforated sheet 1 and the non-perforated sheet 2 according to the order of the perforated sheet 1, the perforated corrugated sheet 4 and the non-perforated sheet 2;

[0038] 3) Cut the perforated porous material 3 into a trapezoidal prism that matches the perforated corrugated plate 4, fill the trapezoidal prism into the space formed by the perforated corrugated plate 4 and the non-perforated thin plate 2, and use epoxy adhesive to cement the connection interface deal with.

[0039] Further, remove oil stains and rust on the perforated corrugated she...

Embodiment 1

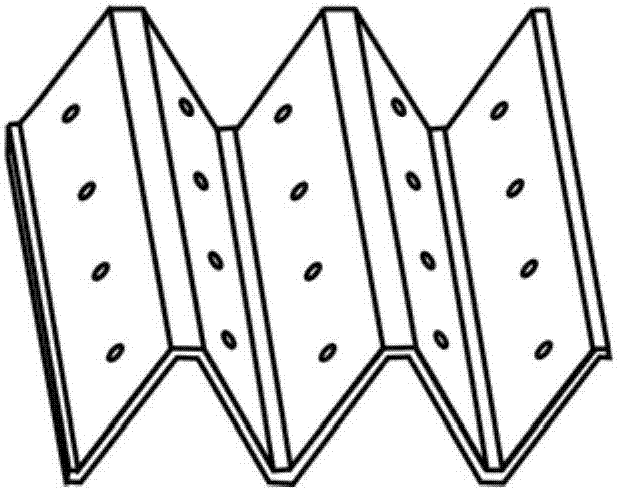

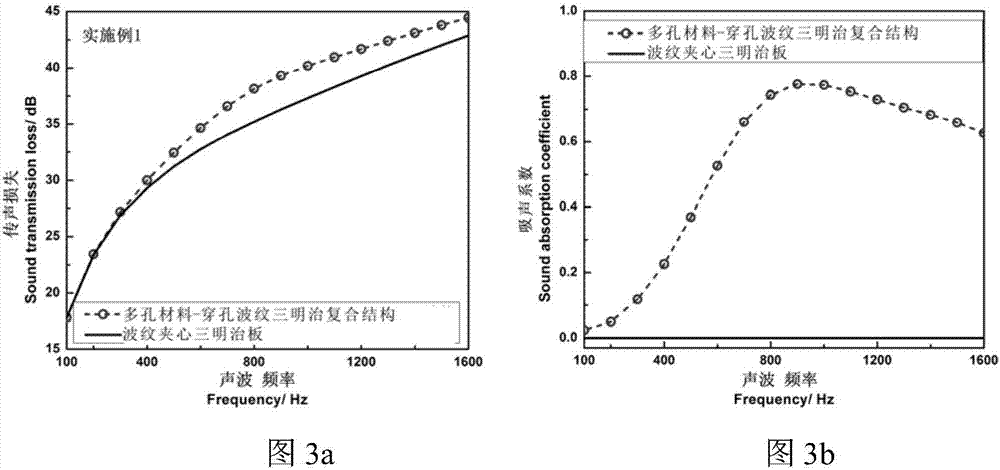

[0042] First, an aluminum plate with a thickness of 1 mm is perforated by a laser cutting machine with a hole diameter of 2 mm and a perforation rate of 0.9%. The perforated board is folded by molding to form a corrugated board with a height of 18mm, see figure 1 . Another aluminum plate with a thickness of 1 mm is perforated by a laser cutting machine with a hole diameter of 2 mm and a perforation rate of 1.4%. A perforated aluminum plate, a perforated corrugated aluminum plate, and another unperforated aluminum plate with a thickness of 1 mm were arranged in sequence by brazing in a vacuum furnace to obtain a perforated aluminum corrugated sandwich panel. Use a cutting machine to cut a piece with a porosity of 97% and a flow resistance of 51200Pa·s / m 2 , the viscous characteristic length is 41 μm, the thermal characteristic length is 59 μm, and the rock wool with the material tortuosity of 1.06 is cut into trapezoidal prisms matching the corrugated sandwich structure, and ...

Embodiment 2

[0044]Firstly, a structural steel plate with a thickness of 1 mm is perforated by a laser cutting machine with a hole diameter of 1.5 mm and a perforation rate of 0.67%. The perforated board is folded by molding to form a corrugated board with a height of 17mm, see figure 1 . Another structural steel plate with a thickness of 1 mm is perforated by a laser cutting machine with a hole diameter of 1.5 mm and a perforation rate of 1.1%. The perforated structural steel, the perforated corrugated steel plate, and another non-perforated structural steel plate with a thickness of 2 mm are sequentially welded by a laser welding machine to obtain a perforated steel corrugated sandwich panel. Use a cutting machine to cut a piece with a porosity of 98% and a flow resistance of 45000Pa·s / m 2 , the viscous characteristic length is 105 μm, the thermal characteristic length is 201 μm, and the sintered metal fiber material with a material tortuosity of 1.05 is cut into trapezoidal prisms tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com