Interlayer cesium-enriched delta-MnO2 catalyst as well as preparation method and application thereof

A catalyst and cesium salt technology are applied in the field of interlayer cesium-rich δ-MnO2 catalyst and its preparation, which can solve the problems of long reaction time and incomplete ion replacement, and achieve simple and easy preparation method, stable product and repeatability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Preparation:

[0032] (1) Dissolve 3mmol of manganese chloride and 30mmol of ammonium bicarbonate in 30ml of ethylene glycol, stir at room temperature until dissolved, then place in an oven, heat to 80°C, and keep the temperature constant for 12h. After the reaction is complete, cool to room temperature, and the obtained product Centrifuge and wash with water and ethanol for several times, and finally put it into a drying oven at 60°C for 12 hours to obtain the precursor manganese carbonate microspheres.

[0033] (2) Mix cesium acetate and precursor manganese carbonate microspheres at a molar ratio of 0.25:1, then place them in a muffle furnace, and raise the temperature to 450°C at a rate of 1°C / min in an air environment, and keep the temperature constant for 3h. Cool to room temperature to obtain interlayer cesium-rich δ-MnO 2 catalyst.

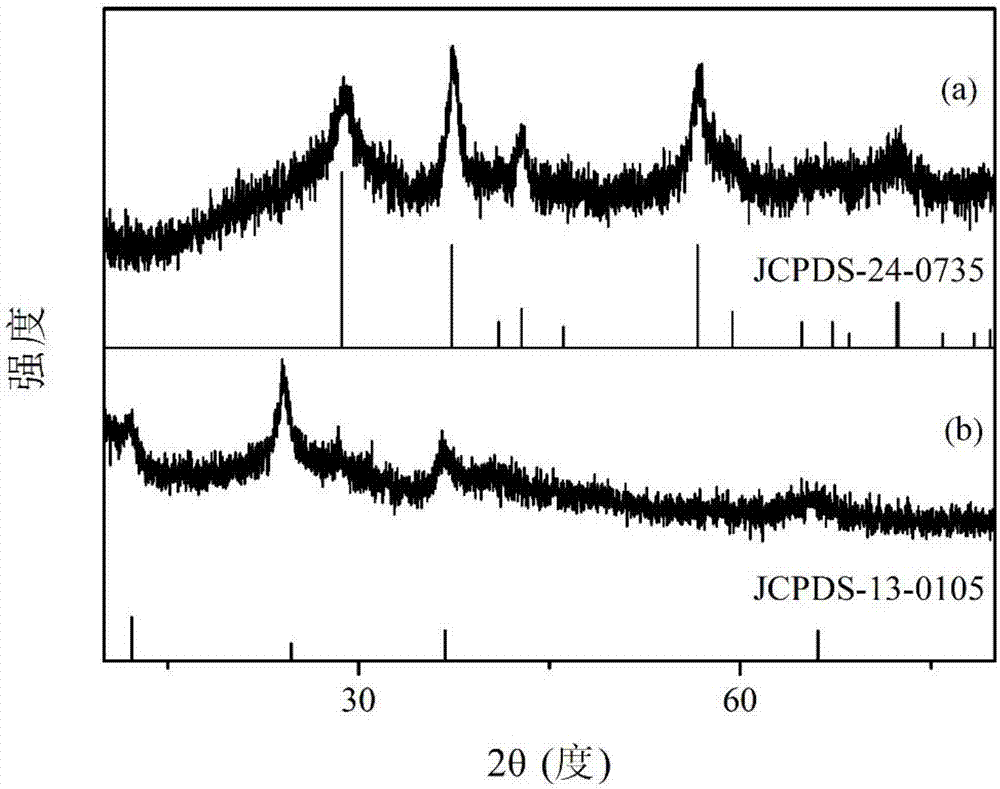

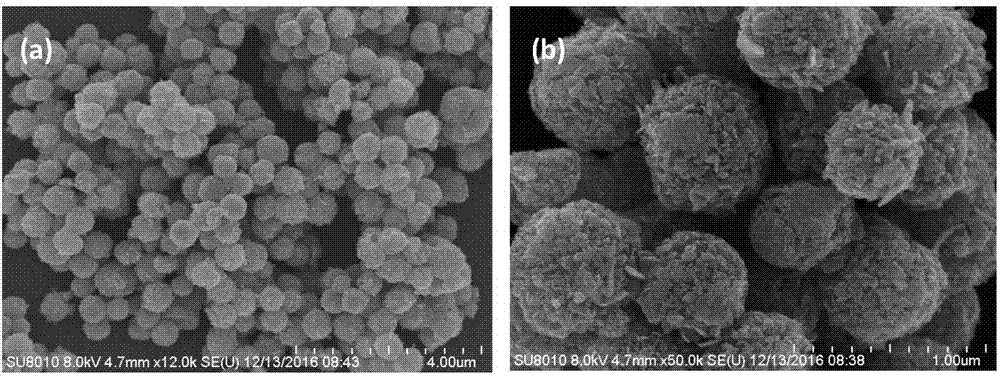

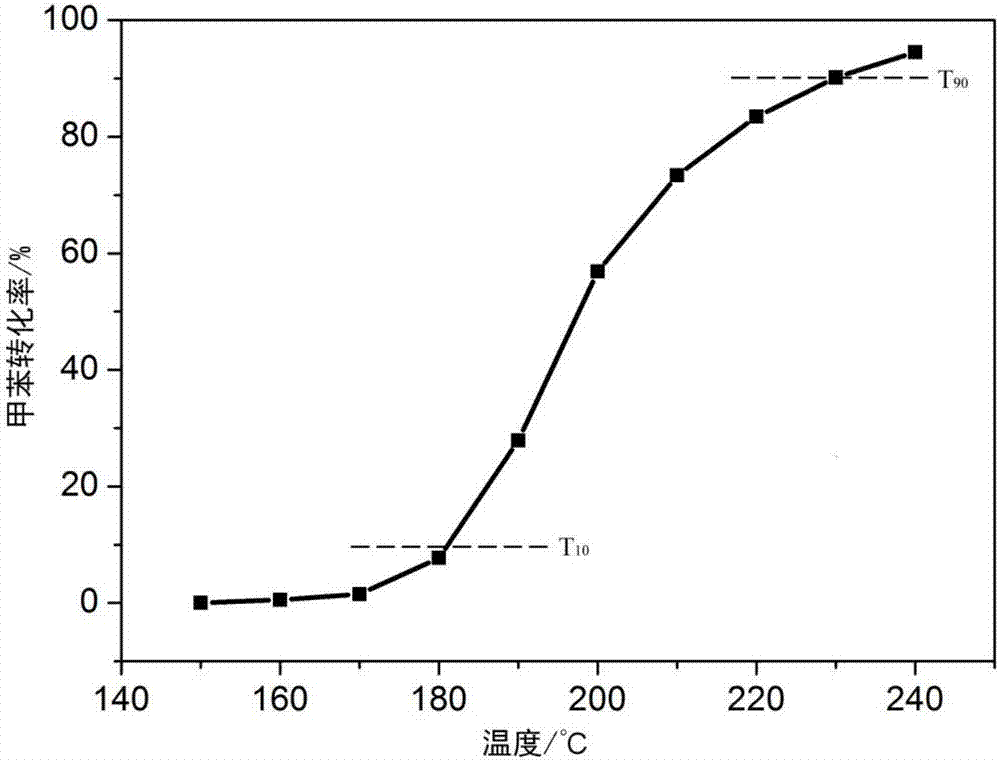

[0034] 2. Performance test: the obtained interlayer cesium-rich δ-MnO 2 The catalyst is characterized by X-ray diffraction an...

Embodiment 2

[0036] Dissolve 3mmol of manganese chloride and 15mmol of sodium bicarbonate in 30ml of ethylene glycol, stir at room temperature until dissolved, then place in an oven, heat to 60°C, and keep the temperature constant for 6h. Centrifuge and wash several times, and finally put it into a drying oven at 60°C for 12 hours to obtain precursor manganese carbonate microspheres, mix cesium nitrate with the obtained precursor manganese carbonate microspheres at a molar ratio of 0.25:1, and then place them in a In the Furnace, in the air environment, the temperature was raised to 450°C at a rate of 1°C / min, kept at a constant temperature for 2h, and cooled to room temperature. The interlayer cesium-rich δ-MnO 2 catalyst.

Embodiment 3

[0038] Dissolve 3mmol of manganese sulfate and 15mmol of ammonium bicarbonate in 30ml of ethylene glycol, stir at room temperature until dissolved, then place in an oven, heat to 80°C, and keep the temperature constant for 6h. After the reaction is complete, cool to room temperature, and centrifuge the resulting product with water and ethanol Wash several times, and finally dry it in a 60°C drying oven for 12 hours to obtain precursor manganese carbonate microspheres. Mix cesium acetate and the obtained precursor manganese carbonate microspheres at a molar ratio of 0.3:1, and then place them in a muffle In the furnace, in the air environment, the temperature was raised to 350°C at a rate of 3°C / min, kept at a constant temperature for 3h, and cooled to room temperature. That is, the interlayer cesium-rich δ-MnO 2 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com