A kind of microfiber/nanofiber composite filter material and preparation method thereof

A technology of microfibers and nanofibers, applied in separation methods, filtration separation, fiber treatment, etc., can solve the problems of complex production process, reduction of filtration resistance, non-reporting, etc., and achieve simple preparation method, strong process controllability, The effect of high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

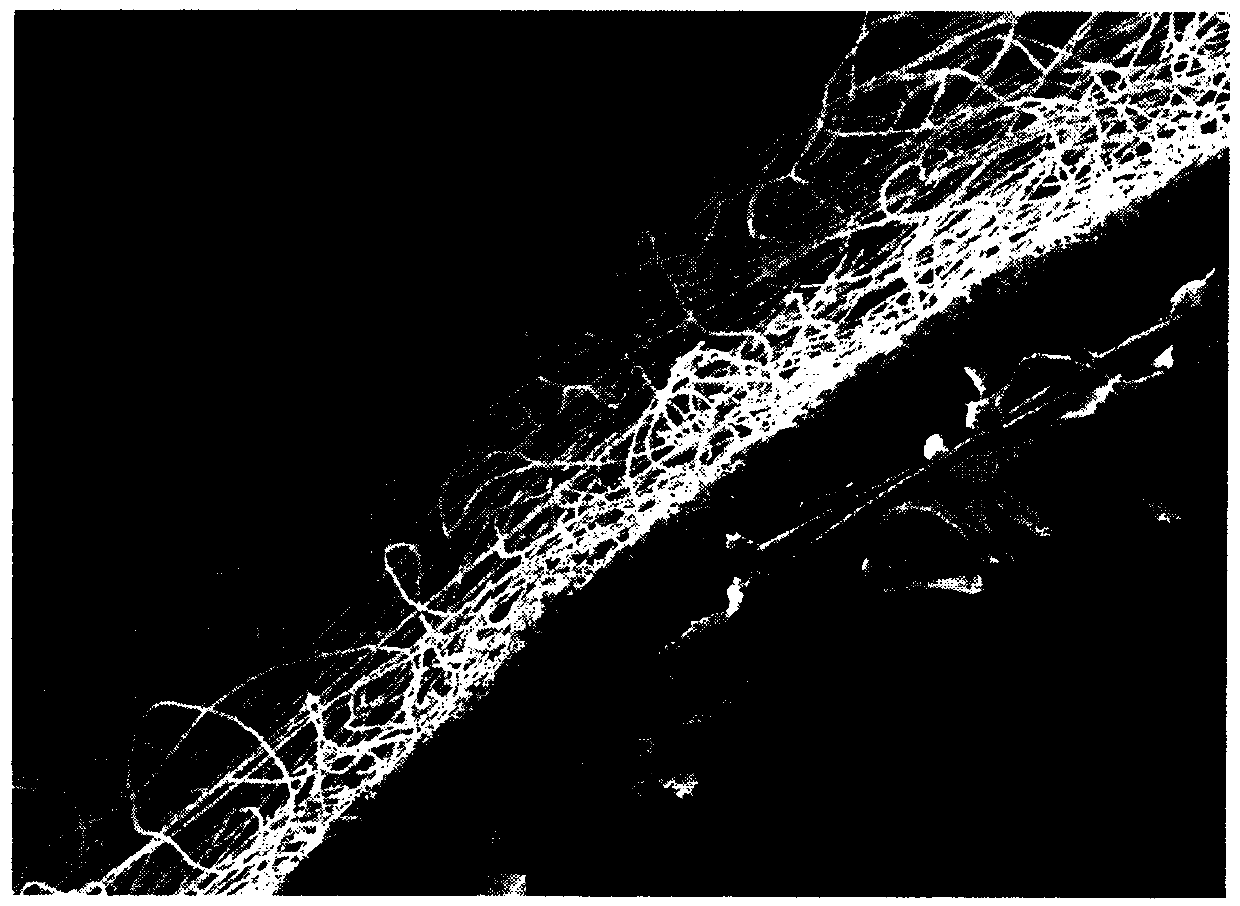

[0030] A microfiber / nanofiber composite filter material and a preparation method thereof, the preparation method mainly comprising the following steps:

[0031]1) Add polyvinylidene fluoride (weight-average molecular weight: 320,000) into N,N-dimethylformamide, seal it and place it in a water bath at 60°C for 10 hours with heating and stirring, and finally prepare a stable and uniform quality Concentration is the polymer spinning liquid A of 20wt%, is used for preparing nanofiber layer;

[0032] Similarly, polystyrene (with a weight average molecular weight of 80,000) was added to N, N-dimethylformamide, and after sealing, it was continuously stirred for 8 hours with a magnetic stirring device, and finally a stable and uniform concentration of 28% was prepared. The polymer spinning liquid B of is used for preparing micron fiber layer;

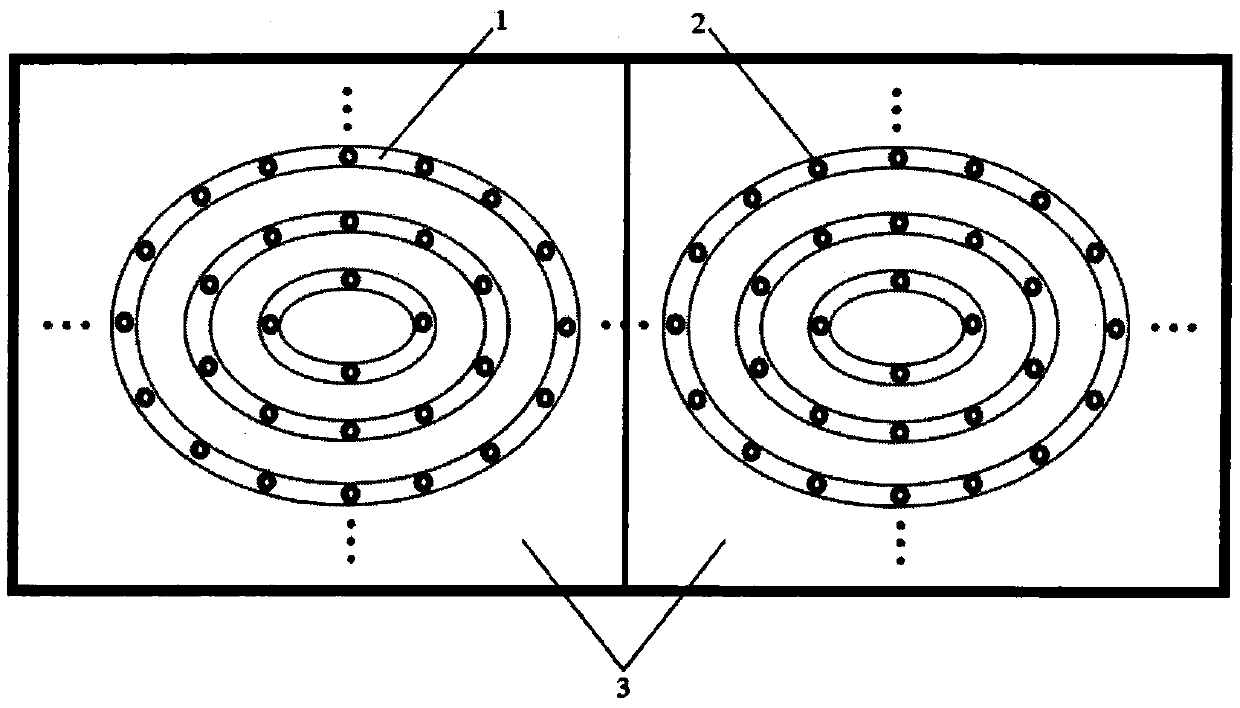

[0033] 2) The prepared polymer spinning solution A and the polymer spinning solution B are sucked into the spinning module through the liquid...

Embodiment 2

[0038] A microfiber / nanofiber composite filter material and a preparation method thereof, the preparation method mainly comprising the following steps:

[0039] 1) Add polyvinylidene fluoride (weight-average molecular weight: 570,000) into N,N-dimethylacetamide, seal it and place it in a water bath at 60°C for 8 hours with heating and stirring, and finally prepare a stable and uniform quality Concentration is the polymer spinning liquid A of 18wt%, is used for preparing nanofiber layer;

[0040] Similarly, polystyrene (with a weight average molecular weight of 80,000) was added to N, N-dimethylformamide, and after sealing, it was continuously stirred for 8 hours with a magnetic stirring device, and finally a stable and uniform concentration of 28% was prepared. The polymer spinning liquid B of is used for preparing micron fiber layer;

[0041] 2) The prepared polymer spinning solution A and the polymer spinning solution B are sucked into the spinning module through the liquid...

Embodiment 3

[0046] A microfiber / nanofiber composite filter material and a preparation method thereof, the preparation method mainly comprising the following steps:

[0047] 1) Add polyvinylidene fluoride (weight-average molecular weight: 570,000) into N,N-dimethylacetamide, seal it and place it in a water bath at 60°C for 8 hours with heating and stirring, and finally prepare a stable and uniform quality Concentration is the polymer spinning liquid A of 18wt%, is used for preparing nanofiber layer;

[0048] Similarly, polysulfone (with a weight-average molecular weight of 70,000) was added to N, N-dimethylacetamide, and after sealing, it was continuously stirred for 15 hours with a magnetic stirring device, and finally a stable and uniform concentration of 29% was prepared. Polymer spinning solution B is used to prepare micron fiber layer;

[0049] 2) The prepared polymer spinning solution A and the polymer spinning solution B are sucked into the spinning module through the liquid supply...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com