Preparation of graphene/poly(1,3,6,8-tetrathiophenepyrene) nano-scroll composite material

A composite material and thiophene pyrene technology, applied in the field of materials, can solve the problems of low power storage capacity of supercapacitors and inability to retain electrons for a long time, and achieve high power storage capacity and electron transmission capacity, stable capacitance value, and increased structural stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

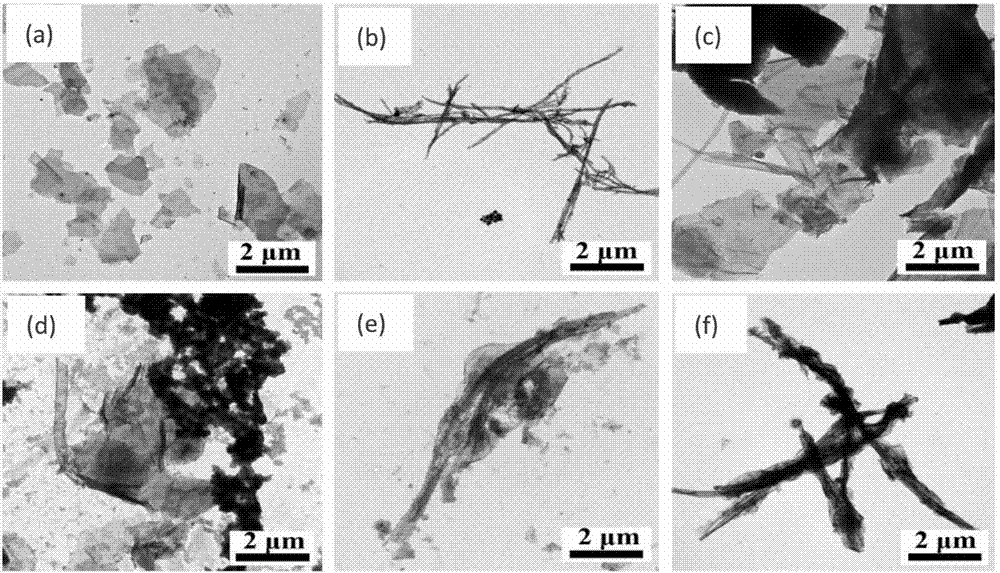

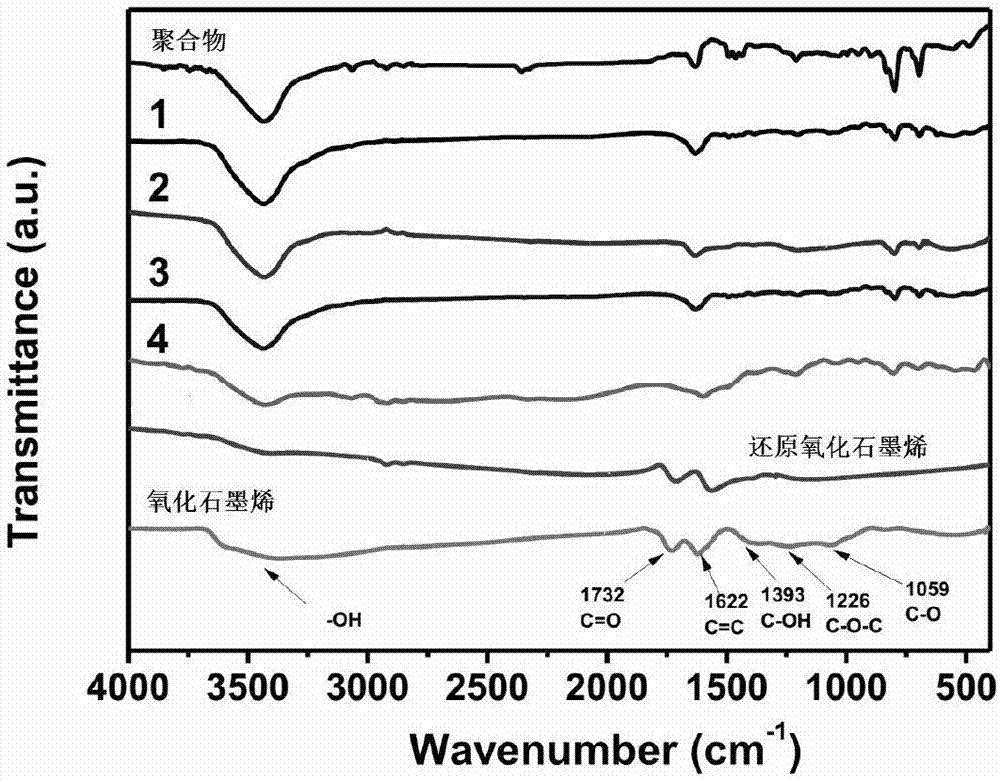

[0025] Example 1: Preparation of poly(1,3,6,8-tetrathienpyrene) and corresponding graphene nanovolumes

[0026] Slowly dissolve 1,3,6,8-tetrathienpyrene (250mg, 0.375mmol) in 12mL of chlorobenzene, and dissolve anhydrous ferric chloride (0.3g.1.6mmol) in nitromethane (1.5mL ), under nitrogen bubbling and stirring, the ferric chloride solution was added dropwise to the 1,3,6,8-tetrathienpyrene solution, and after the addition was complete, the reaction system was placed in a 45-degree oil bath Continue to stir for 24 hours, cool down to room temperature, and after a large amount of solid precipitates, filter the precipitated solid with suction, wash the filtered solid with 30mL × 3 chloroform, and finally obtain orange-red flake poly(1,3,6,8-tetrathienpyrene ). Take 20mg, 10mg graphene oxide and 15mL N,N-dimethylacetamide and disperse them in a 50mL microwave reaction tube, put them into an ultrasonic machine and sonicate for 1 hour to obtain a brick red suspension, add 1.5mL ...

Embodiment 2

[0027] Example 2: Preparation of poly(1,3,6,8-tetrathienpyrene) and corresponding graphene nanovolumes

[0028] Slowly dissolve 1,3,6,8-tetrathienpyrene (500mg, 0.75mmol) in 20mL o-dichlorobenzene, and dissolve anhydrous ferric chloride (0.7g.3.4mmol) in nitromethane ( 4mL), under nitrogen bubbling and stirring, the ferric chloride solution was added dropwise to the 1,3,6,8-tetrathienpyrene solution. After the addition was complete, the reaction system was placed in a 60-degree oil bath Continue to stir for 36 hours, cool down to room temperature, and after a large amount of solids precipitate, the precipitated solids are suction-filtered, and the filtered solids are washed with 30mL×3 chloroform, and finally reddish-brown poly(1,3,6,8-tetrathienpyrene) is obtained. powder. Take 30mg, 30mg of graphene oxide and 25mL of N,N-dimethylacetamide and disperse them in a 50mL microwave reaction tube, put them into an ultrasonic machine and sonicate for 1 hour to obtain a brown-red su...

Embodiment 3

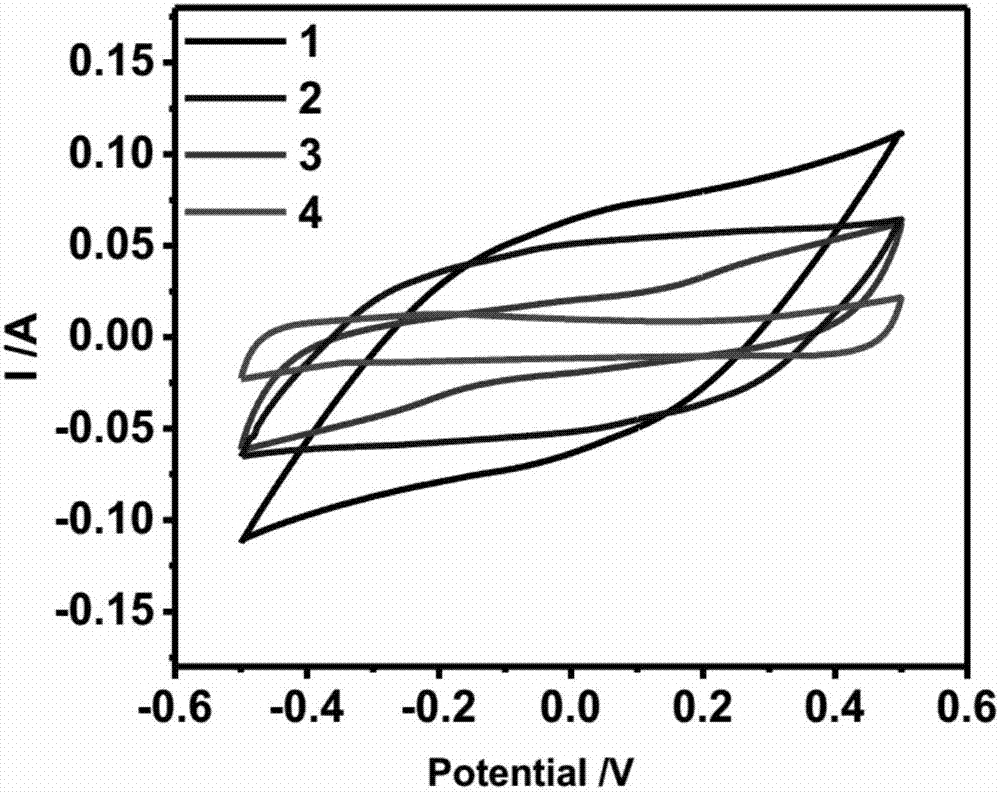

[0029] Embodiment 3: supercapacitor performance test CV test

[0030] In the electrode preparation process, nickel foam is selected as the current collector of the electrode sheet, and the nickel foam electrode sheet is cut into a regular circle, and then the cut electrode sheet is placed in a tablet press and pressed to one-third of the original thickness slices, and then slightly cut around the slices. Finally, the round nickel foam disc was dried in a vacuum oven at 100 °C for 12 h. After drying, weigh the mass of the nickel foam disc and record it as m 0 . The graphene oxide nano-volume prepared in Example 1 is ground into powder, according to the graphene nano-volume of 75:20:5: acetylene black: the proportioning of polytetrafluoroethylene (PTFE), puts into the mortar, adds a little non-toxic Grind water and ethanol clockwise until it becomes a paste, apply a medicine spoon evenly on one side of the nickel foam until the color of the nickel foam itself cannot be seen cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com