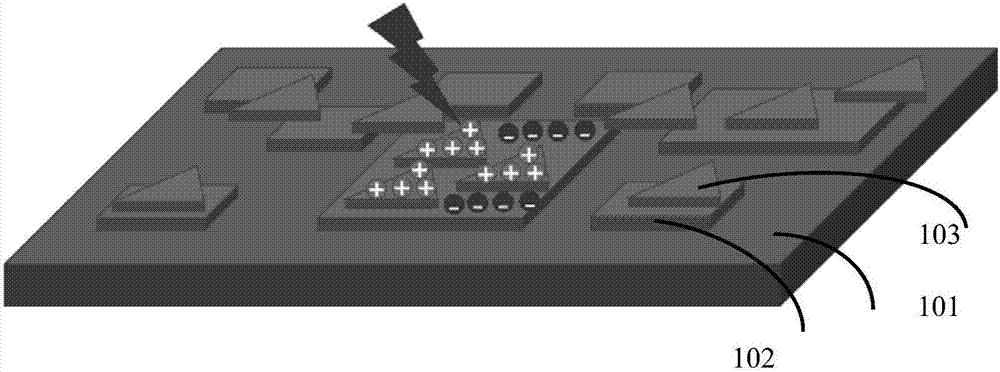

Water purification composite material and preparation method and application thereof

A composite material and water purification technology, applied in chemical instruments and methods, water/sewage treatment, light water/sewage treatment, etc., can solve the problems of low solar energy utilization rate, low water purification rate, low adsorption of pollutants and harmful bacteria, etc. problems, to achieve the effect of improving water purification efficiency, improving decomposition efficiency, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

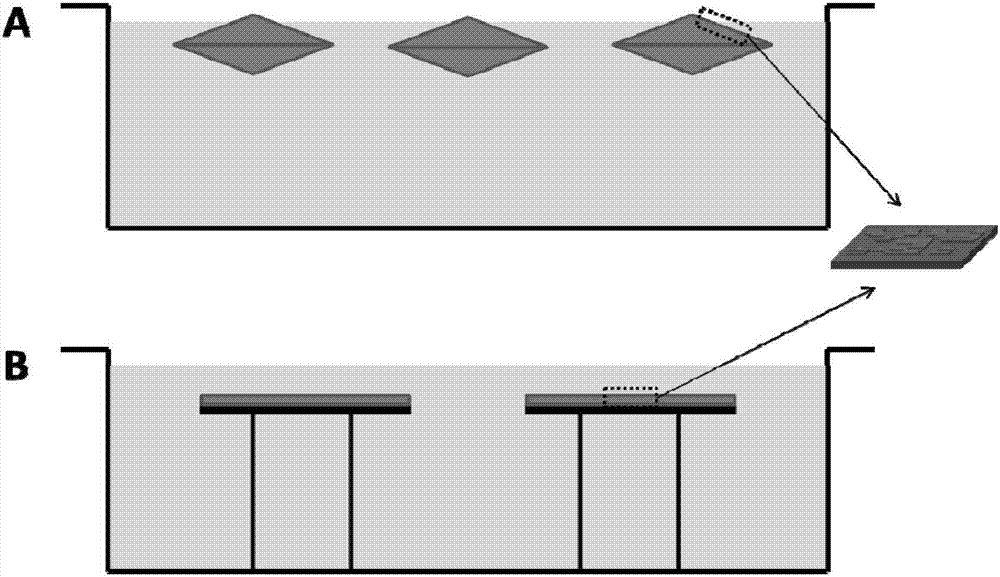

[0046] A preparation method of water purification composite material, comprising the following steps:

[0047] 1. Take the glassy carbon substrate, wash and dry it for later use, and vacuum-deposit a layer of Cu electrode film on the above substrate;

[0048] 2. Graphene oxide is grown onto the surface of the above-mentioned glassy carbon substrate evaporated with Cu electrode film by chemical vapor deposition method, the specific process is as follows:

[0049] Firstly, a layer of Cu electrode film with a thickness of about 10nm is evaporated on the glassy carbon substrate by vacuum thermal evaporation equipment; then, it is placed in a chemical vapor deposition (CVD) tube furnace, vacuumed, heated to 400°C, and put into Ethylene and argon mixed gas, the molar ratio is 1:10, the total gas flow rate is 11mL / min, and the time is 30-60min, so as to obtain graphene with a thickness of 1-5 layers; then, the graphene is oxidized to Graphene oxide. Among them, the thickness of the...

Embodiment 2

[0060] A preparation method of water purification composite material, comprising the following steps:

[0061] 1. Take glassy carbon fibers as the substrate, and grow graphene oxide onto the surface of the substrate. The specific process is: first vapor-deposit copper electrodes on the glassy carbon substrate, and then grow graphene oxide (GO) onto the substrate by vapor-phase chemical deposition according to the above method. On the substrate, the specific steps are as follows: the preparation steps of GO are as follows:

[0062] Firstly, a layer of Cu electrode film with a thickness of about 10nm is evaporated on the glassy carbon substrate through vacuum thermal evaporation equipment; then, it is placed in a chemical vapor deposition (CVD) tube furnace, vacuumed, heated to 380°C, and put into Ethylene and argon mixed gas, the molar ratio is 1:8, the gas flow rate is 9mL / min, and the time is 35min, so as to obtain graphene with a thickness of 1-3 layers; the graphene is oxid...

Embodiment 3

[0067] A preparation method of water purification composite material, comprising the following steps:

[0068] 1, get polyester (PET) film to make substrate, adopt the method identical with embodiment 2 to grow graphene oxide to substrate surface, the physical parameter of the obtained two-dimensional layered graphene oxide is also with embodiment 2;

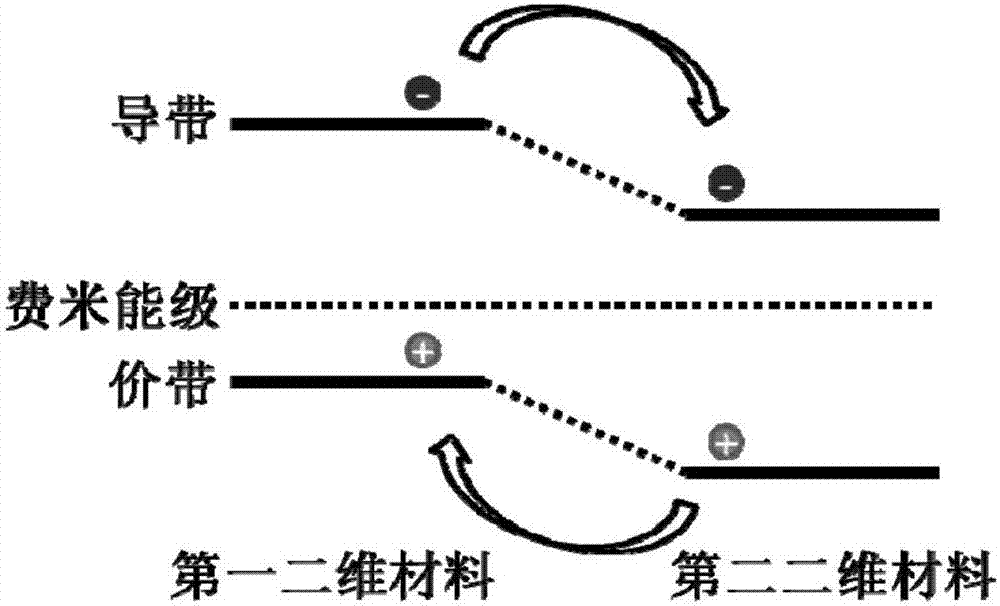

[0069] 2. Preparation of MoS 2 2D materials:

[0070] Weigh 1g MoS 2 The solid was added to 200mL NMP for ultrasonication for 10h, and the ultrasonic power was 500W. After the ultrasonication was completed, it was centrifuged at a speed of 3000rpm for 30min. After centrifugation, the supernatant was collected and further centrifuged at a speed of 8000rpm to collect the lower precipitate to obtain the exfoliated sheet MoS 2 Two-dimensional materials; among them, the prepared MoS 2 The thickness of the two-dimensional material is 1-3nm, the number of layers is 1-3 layers, its band gap is 1.8eV, the valence band energy is -5.7eV...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bandgap | aaaaa | aaaaa |

| To size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com