Preparation method of pumpkin-seed premix-powder base material for baked product

The technology of pumpkin seed powder and pumpkin seeds is applied in the field of preparation of ready-mixed powder base materials for pumpkin seed baked products, which can solve the problems of not entering industrial production, staying in the research stage, etc. The effect of added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

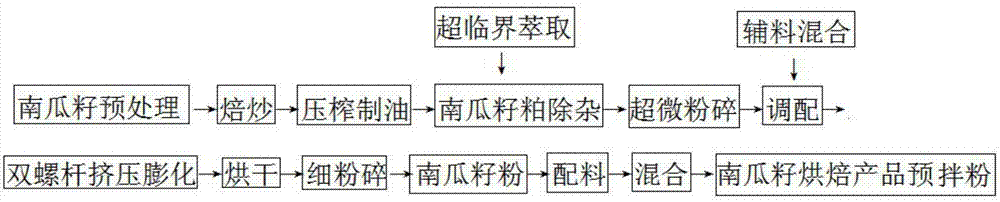

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1, the preparation of pumpkin seed cake premix powder

[0041] (1) Select high-quality pumpkin seeds, and after winnowing and magnetic separation to remove impurities, wash them with water to make them reach edible standards.

[0042] (2) The cleaned pumpkin seeds are roasted in an electric heating rotary frying pan at a temperature of 200°C for 5 minutes, and the feeding amount is 2Kg.

[0043] (3) Use a screw-type oil press for oil extraction, the oil extraction temperature is 120°C, the number of pressings is 2 times, and the residual oil rate is lower than 8%. The pumpkin seed oil obtained by this method of oil extraction is of good quality and does not need to be refined edible.

[0044] (4) Supercritical carbon dioxide fluid extraction removes impurities from the pumpkin seed meal. The extraction temperature is 40° C., the pressure is 25 MPa, the flow rate is 20 L / h, and the residual oil rate is 1%.

[0045] (5) Superfine crushing: the crushing time i...

Embodiment 2

[0050] Embodiment 2, the preparation of pumpkin seed bread premix powder

[0051] (1) Select high-quality pumpkin seeds, and after winnowing and magnetic separation to remove impurities, wash them with water to make them reach edible standards.

[0052] (2) Use a hydraulic oil press to extract the oil, the pressure is 60MPa, and the residual oil rate is about 5%. The pumpkin seed oil obtained by this method is of good quality and can be eaten without refining.

[0053] (3) Superfine crushing: the crushing time is 3 minutes, and the particle size of the crushed material is about 200 mesh.

[0054] (4) Twin-screw extrusion processing: add corn flour to mix and extrude, wherein the mass ratio of pumpkin seed meal to corn flour is 10:1, the particle size of corn flour is 200 mesh to 300 mesh, and the extrusion temperature is 130 ℃, pressure 8MPa, screw speed 280r / min.

[0055] (5) Low-temperature drying and crushing: the temperature of the blast dryer is 60° C., and the moisture...

Embodiment 3

[0058] Embodiment 3: Production of pumpkin seed biscuit premix powder

[0059] (1) Select high-quality pumpkin seeds, and after winnowing and magnetic separation to remove impurities, wash them with water to make them reach edible standards.

[0060] (2) Roast the cleaned pumpkin seeds in an electric heating rotary frying pan at a temperature of 200° C. for 5 minutes.

[0061] (3) Use a hydraulic oil press to press the oil, the pressure is 60MPa, and the residual oil rate is about 5%.

[0062] (4) Superfine crushing: the crushing time is 5 minutes, and the particle size of the crushed material is about 300 mesh.

[0063] (5) Twin-screw extrusion processing: add corn flour to mix and extrude, wherein the mass ratio of pumpkin seed meal to corn flour is 8:1, the particle size of corn flour is 200 mesh to 300 mesh, and the extrusion temperature is 150 °C, pressure 5MPa, screw speed 280r / min.

[0064] (6) Drying and crushing: the temperature of the blast dryer is 105°C, the moi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com