A kind of preparation method of nano microsphere phosphotungstate/sulfur cathode material

A technology of microsphere phosphotungstate and sulfur cathode material, applied in battery electrodes, structural parts, electrical components, etc., to achieve the effect of safe reaction conditions, simple preparation process and strong chemical adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

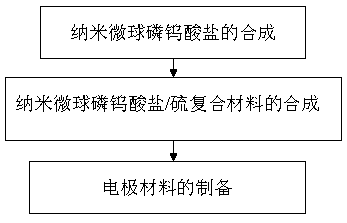

Method used

Image

Examples

Embodiment 1

[0026] Preparation of nano-microsphere potassium phosphotungstate / sulfur cathode material and electrode sheet:

[0027] (1) Preparation of nano-microsphere potassium phosphotungstic acid: take 50ml, 0.19mol / L potassium chloride solution, slowly add potassium chloride solution into 100ml, 0.09mol / L phosphotungstic acid solution, and the reaction temperature is 50°C, magnetic stirring speed 500r / min. The reaction time is 4h. Cool to room temperature after the reaction, wash and dry. Potassium phosphotungstate was prepared with nanometer microspheres. Its scanning electron microscope image is shown in figure 2 .

[0028] (2) Preparation of nano-microsphere potassium phosphotungstate / sulfur composites. Weigh 0.6g of nano-microsphere potassium phosphotungstate and 1.4g of elemental sulfur, put them into an agate ball mill jar, fill the agate ball mill jar with high-purity argon in the glove box and place it on a planetary ball mill for 1 hour. The speed is 300 r / min. Then, ...

Embodiment 2

[0032] Preparation of nano-microsphere ammonium phosphotungstate / sulfur cathode material and electrode sheet:

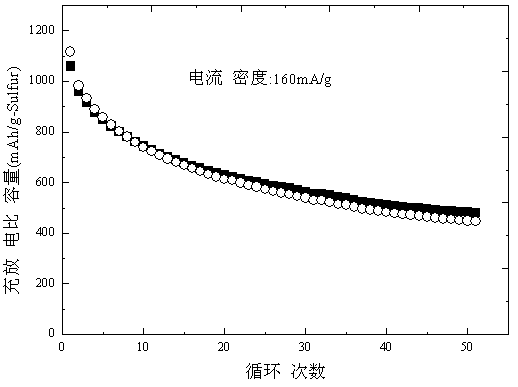

[0033] The potassium chloride solution in step (1) in Example 1 was replaced with ammonium chloride solution, and the reaction time of (1) in Example 1 was replaced from 4h to 8h. In the step (2) of Example 1, the nano-microsphere potassium phosphotungstate was replaced by the nano-microsphere ammonium phosphotungstate, and the others were the same as in Example 1. Under different current densities such as 160mA / g, 320mA / g, 800mA / g, 1600mA / g, 3200mA / g, 8000mA / g, etc., the ladder discharge test results are as follows Figure 4 shown.

Embodiment 3

[0035] Preparation of nano-microsphere cesium phosphotungstate / sulfur cathode material:

[0036] Replace the potassium chloride solution in step (1) in Example 1 with cesium chloride solution, replace the reaction temperature in (1) in Example 1 with 50°C to 60°C, and react (1) in Example 1 The time is 4h replaced by 8h. In the step (2) of Example 1, the nano-microsphere potassium phosphotungstate was replaced by the nano-microsphere cesium phosphotungstate, and the others were the same as in Example 1. Under the current density of 1600mA / g, the test results of charge and discharge cycle life are as follows: Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com