Method for manufacturing REBCO superconducting film and constant-temperature dip-coating device

A technology of rare earth barium copper oxide and superconducting film, which is applied to the equipment used to manufacture conductive/semiconductive layers, the usage of superconducting elements, superconducting devices, etc., and can solve the problem of not considering the control factors of temperature and film thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

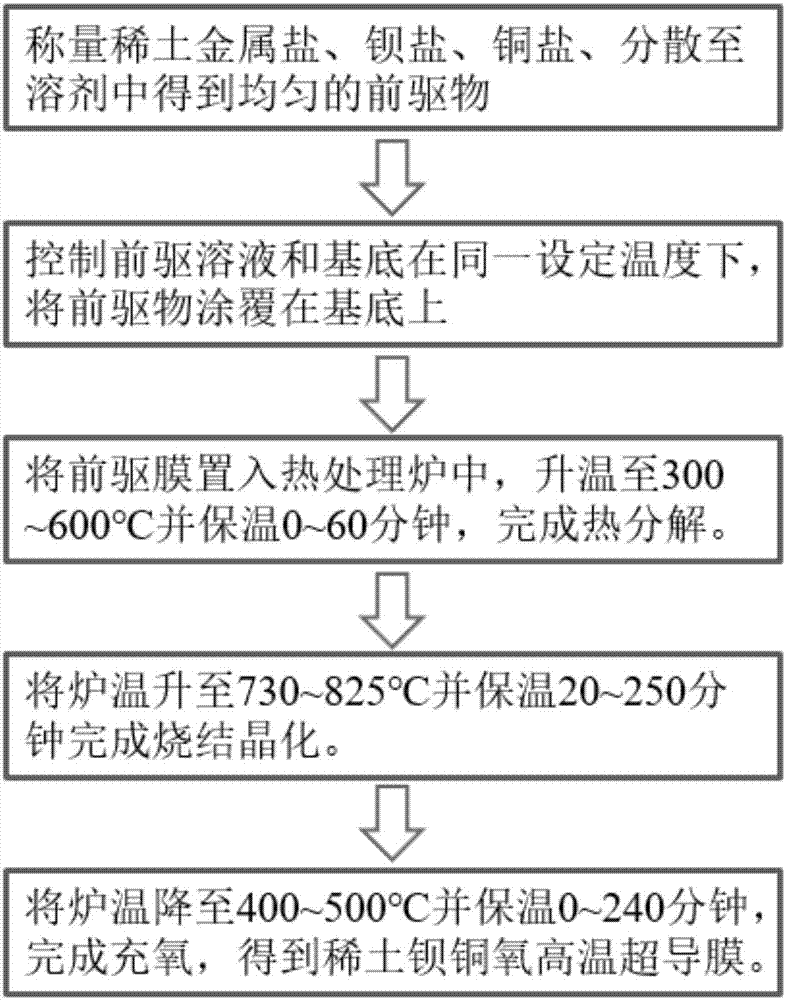

[0064] The preparation process is as figure 1 As shown, first according to the metal cation molar ratio of 1:(1+x):3 (where 0.5≤x≤1), yttrium acetate tetrahydrate, barium acetate and copper acetate monohydrate were dissolved in deionized water, and trifluoroacetic acid was added thereto. After 2 times of rotary evaporation, the above-mentioned metal salt was finally dissolved in methanol to obtain a clear, transparent, dark blue precursor with a concentration of 1.5 mol / L.

[0065] Using an improved water bath, dip-coating was performed at temperatures of 0°C, 10°C, 20°C and 30°C, respectively, and the above precursor solution was coated on LaAlO 3 (lanthanum aluminate) single crystal substrate, and then placed in a tube furnace for rapid heat treatment, the YBCO precursor film can be obtained. The film section thickness was observed with a Hitachi Su8010 scanning electron microscope, and 5 values were taken for each sample to eliminate errors. Dip-coating at different co...

example 2

[0068] According to a method of preparing a solution according to the embodiment, the preparation concentration is a precursor of 1.8mol / L, and then the precursor is added with a mass fraction of 25% polyethylene glycol 2000 (PEG2000), and the modification is obtained after fully stirring, dissolving and standing. precursors. By improving the temperature control of the water bath, dip-coating was carried out at temperatures of 0°C, 10°C, 20°C and 30°C, respectively, and the above precursor solution was applied to LaAlO by dip-coating technology. 3 (lanthanum aluminate) single crystal substrate, and then placed in a tube furnace for rapid heat treatment, the YBCO precursor film can be obtained. The film section thickness was observed with a Hitachi Su8010 scanning electron microscope, and 5 values were taken for each sample to eliminate errors. Dip-coating at different constant temperatures of 0°C, 10°C, 20°C, and 30°C, the thickness of the film is divided into 548nm, 493nm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com