Zr and Sr compound microalloyed and Mn microalloyed high toughness Al-Si-Cu serial cast aluminum alloy and preparation method thereof

A technology for casting aluminum alloy and micro-alloying, which is applied in the field of new high-strength and tough Al-Si-Cu series cast aluminum alloy and its preparation, can solve the problems of reducing alloy casting performance, low plasticity and toughness, etc. The effect of dense tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

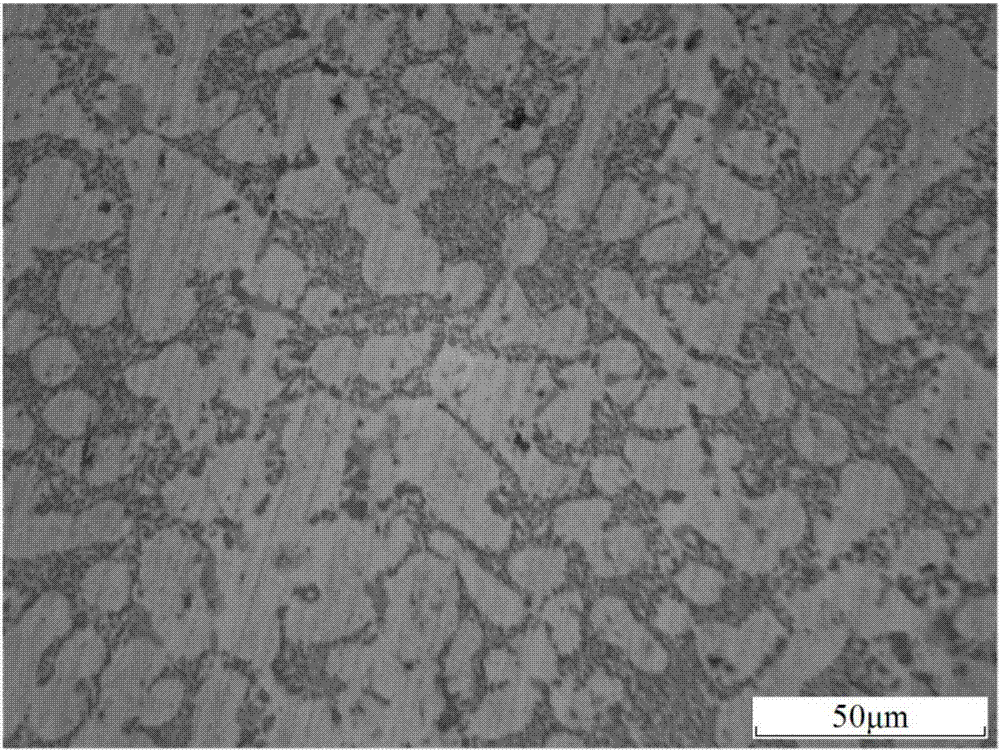

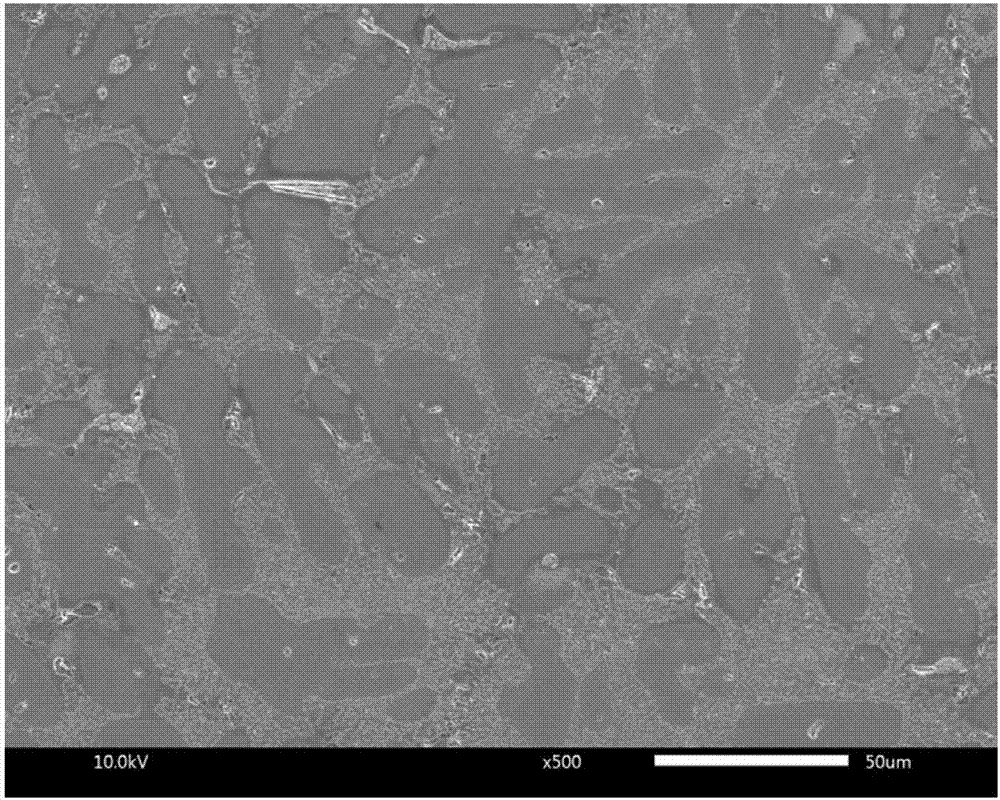

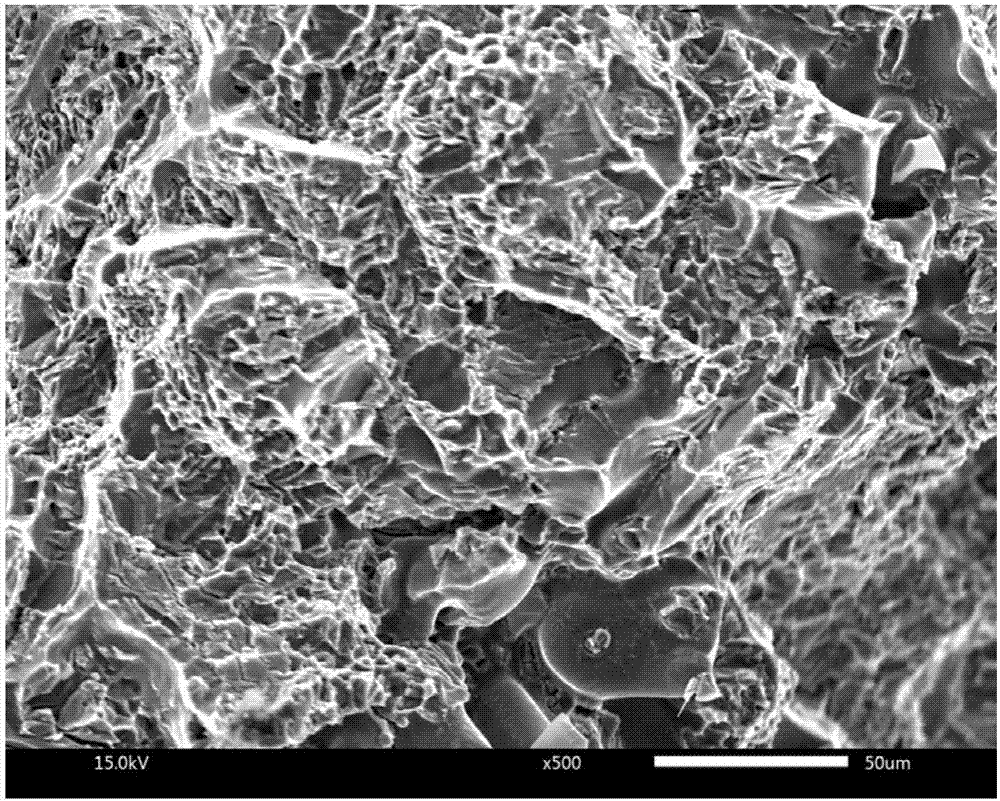

[0031] Such as figure 1 , 2 , 3, 4 shown.

[0032] A Zr, Sr composite microalloying and Mn alloying high strength and toughness Al-Si-Cu cast aluminum alloy, its preparation method:

[0033]First melt A00 grade pure Al (99.79%Al, 0.14%Fe, 0.04%Si) and Al-Si (89.62%Al, 10.21%Si, 0.17%Fe) master alloy, then heat up to 850±10℃, and then add Al-Cu (49.62%Al, 50.12%Cu, 0.15%Fe, 0.11%Si ) master alloy, Al-Mn (89.73% Al, 10.02%Mn, 0.19%Fe, 0.06%Si ) master alloy, Al-Zr ( 95.69%Al, 4.11%Zr, 0.20% Fe, 0.10%Si ) master alloy and Al-Sr(89.86%Al, 9.89%Sr, 0.15%Fe, 0.10%Si ) master alloy; after all master alloys and metals are melted Adjust the temperature to 750±10°C, add hexachloroethane for refining and degassing until no gas escapes, let it stand for 5-10 minutes, then remove the slag and pour it into a metal mold preheated to 300±10°C to cast an ingot; That is, a high-strength and tough Al-Si-Cu cast aluminum alloy with Zr, Sr composite microalloying and Mn alloying is obtained. ...

Embodiment 2

[0037] A Zr, Sr composite microalloying and Mn alloying high strength and toughness Al-Si-Cu cast aluminum alloy, its preparation method:

[0038] First melt A00 grade pure Al (99.79%Al, 0.14%Fe, 0.04%Si) and Al-Si (89.62%Al, 10.21%Si, 0.17%Fe) master alloy, then heat up to 850±10℃, and then add Al-Cu (49.62%Al, 50.12%Cu, 0.15%Fe, 0.11%Si ) master alloy, Al-Mn (89.73%Al, 10.02%Mn, 0.19%Fe, 0.06%Si ) master alloy, Al-Zr ( 95.69%Al, 4.11%Zr, 0.20%Fe, 0.10%Si ) master alloy and Al-Sr(89.86%Al, 9.89%Sr, 0.15%Fe, 0.10%Si ) master alloy; after all master alloys and metals are melted Adjust the temperature to 750±10°C, add hexachloroethane for refining and degassing until no gas escapes, let it stand for 5-10 minutes, then remove the slag and pour it into a metal mold preheated to 300±10°C to cast an ingot; That is, a high-strength and tough Al-Si-Cu cast aluminum alloy with Zr, Sr composite microalloying and Mn alloying is obtained.

[0039] The composition of the Zr, Sr composite...

Embodiment 3

[0042] A Zr, Sr composite microalloying and Mn alloying high strength and toughness Al-Si-Cu cast aluminum alloy, its preparation method:

[0043] First melt A00 grade pure Al (99.79%Al, 0.14%Fe, 0.04%Si) and Al-Si (89.62%Al, 10.21%Si, 0.17%Fe) master alloy, then heat up to 850±10℃, and then add Al-Cu (49.62%Al, 50.12%Cu, 0.15%Fe, 0.11%Si ) master alloy, Al-Mn (89.73% Al, 10.02%Mn, 0.19%Fe, 0.06%Si ) master alloy, Al-Zr ( 95.69%Al, 4.11%Zr, 0.20% Fe, 0.10%Si ) master alloy and Al-Sr(89.86%Al, 9.89%Sr, 0.15%Fe, 0.10%Si ) master alloy; after all master alloys and metals are melted Adjust the temperature to 750±10°C, add hexachloroethane for refining and degassing until no gas escapes, let it stand for 5-10 minutes, then remove the slag and pour it into a metal mold preheated to 300±10°C to cast an ingot; That is, a high-strength and tough Al-Si-Cu cast aluminum alloy with Zr, Sr composite microalloying and Mn alloying is obtained.

[0044] The composition of the Zr, Sr composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com