A kind of high plasticity, high strength casting beryllium aluminum alloy and preparation method thereof

A beryllium aluminum alloy and alloy technology, which is applied in the field of non-ferrous metal alloy preparation, can solve the problems of poor plasticity, low strength, and difficult casting defects of beryllium aluminum alloy, and achieve the effects of improving plasticity, low cost, and increasing alloy hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A high-plasticity, high-strength cast beryllium aluminum alloy, comprising: beryllium (Be) 60%, aluminum (Al) 38%, nickel (Ni) 1.0%, lithium (Li) 0.5%, germanium (Ge) 0.5% according to mass percentage %, and the rest are unavoidable impurities.

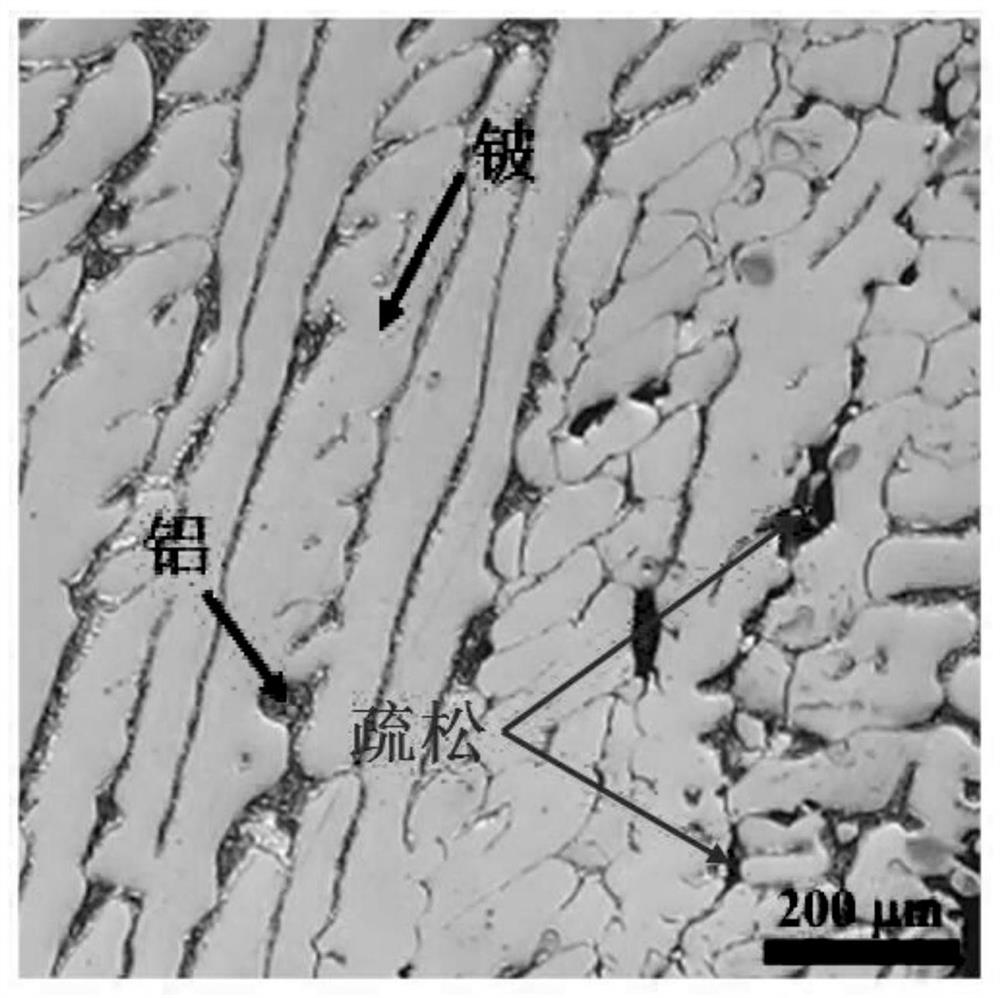

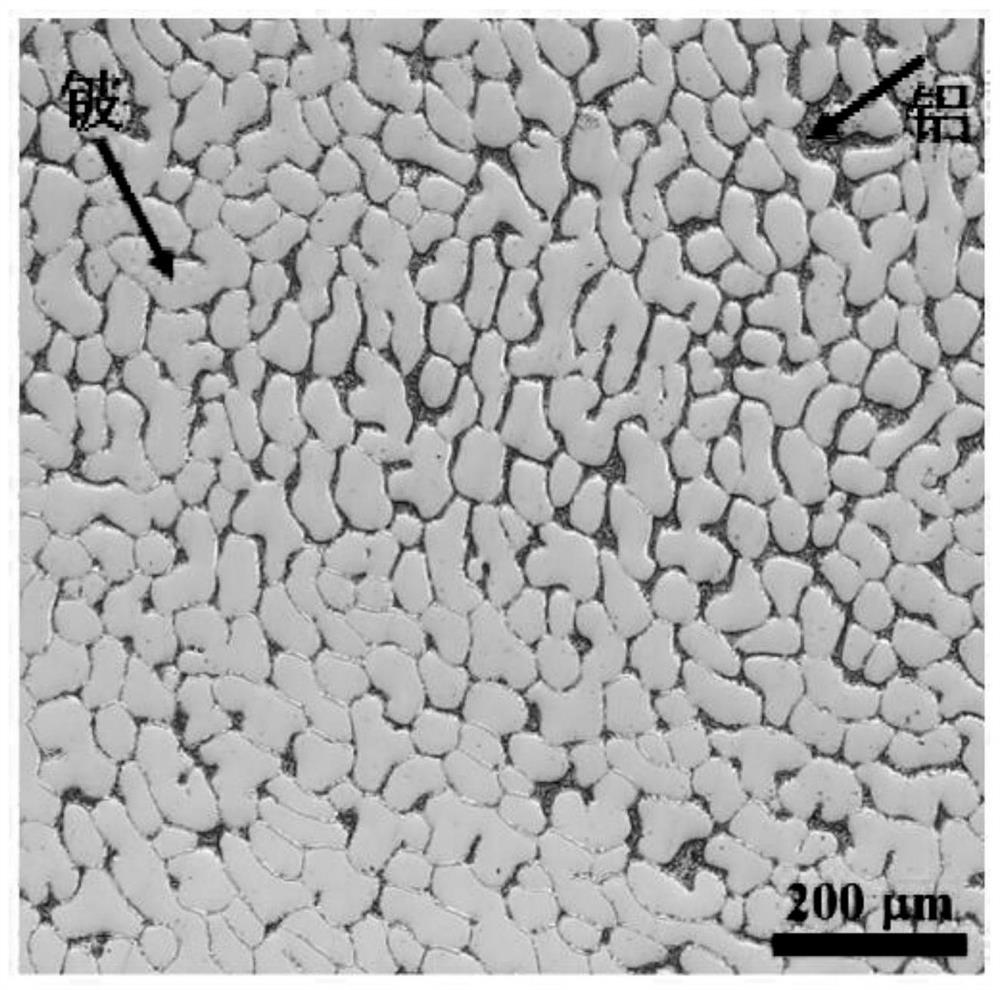

[0034] A method for preparing the above-mentioned beryllium aluminum alloy, comprising the following steps: vacuuming the cavity of the vacuum induction melting furnace to 2.0×10 -2 After the Pa is filled with high-purity argon gas of 0.1 standard atmospheric pressure, the prepared alloy raw materials are placed in a graphite crucible and preheated at 200°C for 10 minutes. Turn on the power to raise the temperature of the raw material to 1430°C and keep it warm for 15 minutes, then cool it down to 1380°C and keep it warm for 4 minutes, and then pour it into an ingot at 1360°C. After coming out of the furnace, the alloy ingot was homogenized and heat-treated in argon at 560°C for 24 hours, and then water-quenched at room temper...

Embodiment 2

[0040] A high-plasticity, high-strength cast beryllium aluminum alloy, comprising: beryllium (Be) 65%, aluminum (Al) 33%, nickel (Ni) 0.7%, lithium (Li) 0.3%, germanium (Ge) 1.0% by mass percentage %, and the rest are unavoidable impurities.

[0041] A method for preparing the above-mentioned beryllium-aluminum alloy, comprising the steps of: evacuating the cavity of a vacuum induction melting furnace to 1.5×10- 2After the Pa is filled with high-purity argon gas of 0.2 standard atmospheric pressure, the prepared alloy raw materials are placed in a graphite crucible and preheated at 150°C for 30 minutes. Turn on the power to raise the temperature of the raw material to 1450°C and keep it warm for 12 minutes, then cool it down to 1360°C and keep it warm for 6 minutes, and then pour it into an ingot at 1350°C. After being released from the furnace, the alloy ingot was homogenized and heat-treated in argon at 540°C for 36 hours, and then water-quenched at room temperature. Carry...

Embodiment 3

[0046] A high-plasticity, high-strength cast beryllium-aluminum alloy, composed according to mass percentage: beryllium (Be) 56%, aluminum (Al) 42%, nickel (Ni) 0.8%, lithium (Li) 0.6%, germanium (Ge) 0.6% %, and the rest are unavoidable impurities.

[0047] A method for preparing the above-mentioned beryllium-aluminum alloy, comprising the following steps: the method for preparing the above-mentioned high-strength, high-plasticity cast beryllium-aluminum alloy is as follows: evacuate the cavity of the vacuum induction melting furnace to 2.0×10- 2 After Pa, it is filled with high-purity argon gas of 0.4 standard atmospheric pressure, and the prepared alloy raw materials are placed in a graphite crucible and preheated at 180°C for 20 minutes. Turn on the power to raise the temperature of the raw material to 1400°C and keep it warm for 20 minutes, then cool it down to 1350°C and keep it warm for 8 minutes, and then pour it into an ingot at 1340°C. After coming out of the furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com