A kind of environment-friendly superfine grinding oil and preparation method thereof

An ultra-fine grinding and environmentally friendly technology, applied in the field of grinding oil, which can solve the problems of substandard surface roughness, reduced workpiece machining accuracy, and greater harm to operators and the environment, so as to ensure that the environment and operators are harmless and guaranteed. Machining accuracy and hardness, and the effect of reducing residue on the surface of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A preparation method of environment-friendly superfine grinding oil, comprising the steps of:

[0040] 1) Each component is measured separately according to the proportioning ratio for use;

[0041] 2) Put the mineral base oil into the blending kettle, stir and heat up to 70-80°C;

[0042] 3) Add antioxidant and stir for 20-30 minutes;

[0043] 4) After cooling down to 50-60°C, add ester base oil, extreme pressure anti-wear agent, metal deactivator, oil mist inhibitor and anti-foaming agent in sequence, and stir each of the above components for 20 ~30min until completely dissolved, then add the next component;

[0044] 5) After all the components are put in, keep the temperature at 50-60°C and stir for more than 1 hour;

[0045] 6) Filter with a bag filter with a precision of 3 μm, pack and store.

[0046] The specific technical index of environment-friendly type ultrafine grinding oil of the present invention is shown in Table 1:

[0047] Table 1 Technical indicat...

Embodiment 1

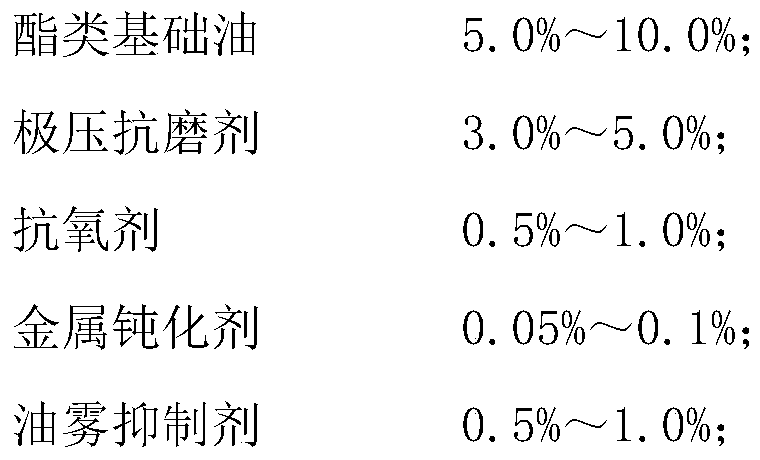

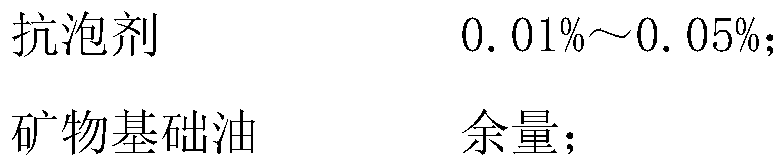

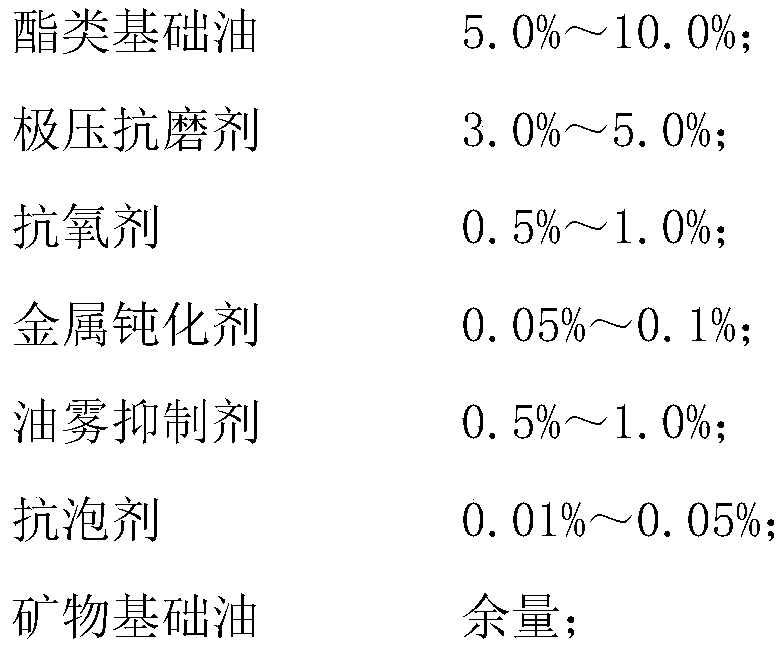

[0051] A kind of environment-friendly type ultra-finishing grinding oil, is made up of following components by weight percentage:

[0052] Refined naphthenic base oil (mineral base oil): 91.43%;

[0053] Isooctyl oleate (ester base oil): 5.0%;

[0054] High base value calcium sulfonate (extreme pressure antiwear agent): 3.0%;

[0055] Di-tert-dodecyl trisulfide (extreme pressure antiwear agent): 0.5%;

[0056] Thioether-based high molecular weight phenol (antioxidant): 0.5%;

[0057] Tolyltriazole derivatives (metal deactivators): 0.05%;

[0058] Polyisobutylene (oil mist inhibitor): 0.5%;

[0059] Silicone ether compound antifoaming agent (antifoaming agent): 0.02%.

[0060] The preparation method of the environment-friendly ultra-fine grinding oil described in this example includes the following steps: put the refined naphthenic base oil into the blending kettle after metering, stir and raise the temperature to 70°C, put in the sulfide-based high molecular weight phenol...

Embodiment 2

[0062] A kind of environment-friendly type ultra-finishing grinding oil, is made up of following components by weight percentage:

[0063] Refined naphthenic base oil (mineral base oil): 82.9%;

[0064] Isooctyl oleate (ester base oil): 10.0%;

[0065] High base value calcium sulfonate (extreme pressure antiwear agent): 4.5%;

[0066] Di-tert-dodecyl trisulfide (extreme pressure antiwear agent): 0.5%;

[0067] Thioether-based high molecular weight phenol (antioxidant): 1.0%;

[0068] Tolyltriazole derivatives (metal deactivators): 0.05%;

[0069] Polyisobutylene (oil mist inhibitor): 1.0%;

[0070] Silicon ether type composite antifoaming agent (antifoaming agent): 0.05%.

[0071] The preparation method of the environment-friendly ultra-fine grinding oil described in this example includes the following steps: put the refined naphthenic base oil into the blending kettle after metering, stir and heat up to 80°C, put in the sulfide-based high molecular weight phenol and stir f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com