A method for extracting and separating catalytic cracking oil slurry

A catalytic cracking oil slurry and extraction technology, which is applied in the petroleum industry, refining hydrocarbon oil, and only multi-stage series refining process treatment, etc., can solve problems such as insufficient separation, improve low utilization rate, avoid catalyst poisoning, alleviate The effect of wasting resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

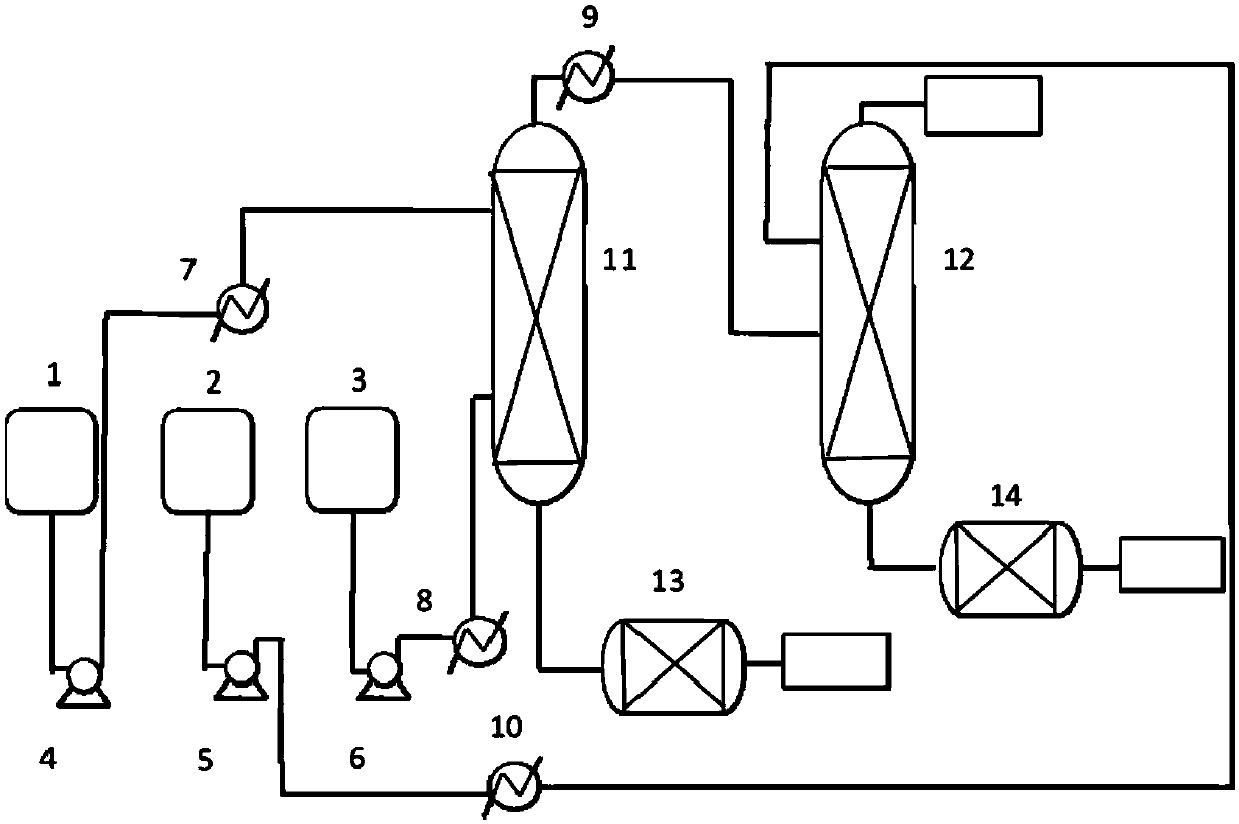

[0039] This embodiment provides a method for extracting and separating catalytic cracking oil slurry, which is carried out by using an extraction tower. The specific process is as follows figure 1 shown. The method includes the following steps:

[0040] Using dimethyl sulfoxide as the solvent 1, make it enter the upper part of the first-stage extraction tower 11, and the oil slurry 1 enters the lower part of the first-stage extraction tower 11, the solvent-oil mass ratio is 3:1, the temperature is 70°C, and the pressure It is 1MPa, and the two are countercurrently contacted in the tower, and the component discharged from the bottom of the first-stage extraction tower 11 is the colloidal component, and enters the solvent evaporator 13;

[0041] The extraction phase of the first-stage extraction tower 11 enters the bottom of the second-stage extraction tower 12 from the top of the tower, the solvent 2 is furfural, and enters the upper part of the second-stage extraction tower 1...

Embodiment 2

[0052] This embodiment provides a method for extracting and separating catalytic cracking oil slurry, which is carried out by using an extraction tower. The specific process is as follows figure 1 shown. The method includes the following steps:

[0053] Using dimethyl sulfoxide as the solvent 1, make it enter the upper part of the first-stage extraction tower 11, and the oil slurry 1 enters the lower part of the first-stage extraction tower 11, the solvent-oil mass ratio is 3:1, the temperature is 75°C, and the pressure It is 1.2MPa, and the two are countercurrently contacted in the tower, and the component discharged from the bottom of the first stage extraction tower 11 is the colloidal component, and enters the solvent evaporator 13;

[0054] The extraction phase of the first-stage extraction tower 11 enters the bottom of the second-stage extraction tower 12 from the top of the tower, the solvent 2 is furfural, and enters the upper part of the second-stage extraction tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com