Cross-linked polyimide aerogel preparation method

A technology of polyimide and airgel, which is applied in the field of preparation of cross-linked polyimide airgel, can solve the problems of poor mechanical properties, obvious shrinkage, high industrial production cost, etc., and achieves low cost and efficient method Simple, low shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

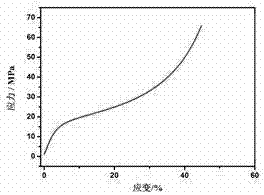

Embodiment 1

[0024] Dissolve biphenyltetracarboxylic dianhydride and 4,4'-diaminodiphenyl ether (dianhydride: diamine = 1mmol: 0.81mmol) in 12g of NMP and react at low temperature for 12 hours to prepare viscous polyamic acid ( PAA) solution, then add 0.12mmol of melamine crosslinking agent, continue to stir at low temperature for 12h, add 14.49g of dehydrating agent (pyridine: acetic anhydride = 6.33:8.16), stir rapidly and then gel at room temperature. After 24 hours, the mixed solution of NMP and acetone was used to replace the solution three times, each time for 8-24 hours. Then use pure acetone to replace the solvent for 3 times, each time for 8-24 hours, and finally perform supercritical drying to obtain a polyimide airgel membrane material or a monolithic material. The porosity of the obtained ordered polyimide airgel is 84%, and the BET specific surface area is 337m 2 / g, the density is 0.22g / cm 3 , the compressive strength (25%) is 32MPa, and the thermal decomposition temperatur...

Embodiment 2

[0026] Dissolve biphenyltetracarboxylic dianhydride and 4,4'-diaminodiphenyl ether (dianhydride: diamine = 1 mmol: 0.90 mmol) in 13.1 g of NMP and react at low temperature for 12 hours, then add 0.06 mmol of melamine The mixture was continuously stirred at low temperature for 12 h to obtain a viscous PAA solution, and 14.49 g of dehydrating agent (pyridine: acetic anhydride = 6.33 : 8.16) was added, and after rapid stirring, it was allowed to gel at room temperature. After 24 h, the solution was replaced three times with a mixed solution of NMP and acetone, each time for 8-24 h. The gel is then replaced with pure acetone for 3 times of solvent, each time for 8-24 hours, and finally supercritically dried to obtain a polyimide airgel membrane material or a monolithic material. The porosity of the obtained polyimide airgel is 76%, and the BET specific surface area is 281m 2 / g with a density of 0.27g / cm 3 , and the tensile strength is 11.8 MPa.

Embodiment 3

[0028] Dissolve biphenyltetracarboxylic dianhydride and 4,4'-diaminodiphenyl ether (dianhydride: diamine = 1 mmol: 0.93 mmol) in 13.4 g of NMP and react at low temperature for 12 hours to prepare a viscous PAA solution. Then add 0.04mmol of melamine cross-linking agent, continue to stir at low temperature for 12h, add 14.49g of dehydrating agent (pyridine: acetic anhydride = 6.33: 8.16), stir rapidly until it gels at room temperature. After 24 hours, the mixed solution of NMP and acetone was used to replace the solution three times, each time for 8-24 hours. The gel is then replaced with pure acetone for 3 times of solvent, each time for 8-24 hours, and finally supercritically dried to obtain the polyimide airgel monolithic material. Nitrogen adsorption and desorption test The porosity of polyimide airgel is 61%, and the BET specific surface area is 230m 2 / g, the density is 0.31g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com