Copolymerized nylon powder material for selective laser sintering and preparation method thereof

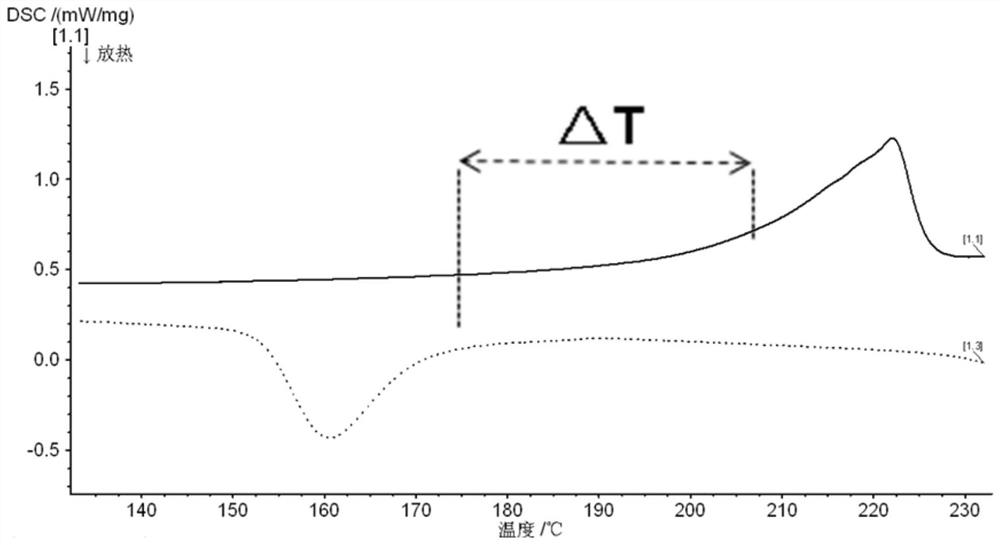

A technology of copolymerized nylon and powder materials, which is applied in the field of additive manufacturing, can solve the problems of limitation and high melting point, and achieve the effects of reduced production cost, good toughness and wide sintering window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

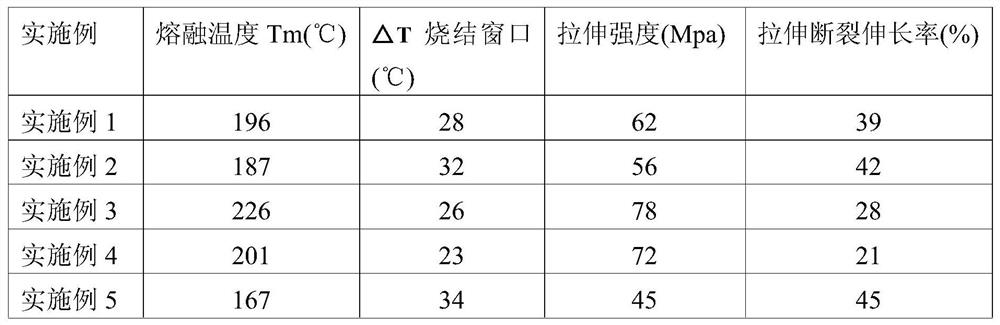

Examples

Embodiment 1

[0027] Step 1: Add PA1010 salt, caprolactam, molecular weight modifier, deionized water, and antioxidant into the polymerization kettle. Wherein the mass ratio of PA1010 salt and caprolactam is 3:7 (calculated by 10 parts), and the ratio of the sum of the mass of PA1010 salt and caprolactam to the molecular weight modifier, deionized water, and antioxidant quality is 88.4%: 0.8%: 10 %: 0.8%; airtight, vacuumize, and then pass in carbon dioxide gas to protect 0.18MPa, raise the temperature to 210°C, the pressure reaches 1.5MPa, keep the pressure for 0.5h, then slowly release the gas to normal pressure, raise the temperature to 250°C and keep the reaction for 2.5h , stop heating, water-cool the strands to discharge, pelletize, and obtain copolymerized nylon pellets.

[0028] Step 2: Prepare nylon copolymer powder by cryogenic crushing. In the crushing process, the crushing temperature in the crushing chamber is controlled at -125±5°C, the rotor clearance is adjusted to 0.5mm, th...

Embodiment 2

[0032] Step 1: Add PA1010 salt, caprolactam, molecular weight modifier, deionized water, and antioxidant into the polymerization kettle. Wherein the mass ratio of PA1010 salt and caprolactam is 7:3 (according to 10 parts), and the ratio of PA1010 salt, the mass ratio of caprolactam and molecular weight modifier, deionized water, antioxidant quality is 79.2%: 0.4%: 20 %: 0.4%; airtight, vacuumize, and then pass into carbon dioxide gas protection 0.18MPa. Raise the temperature to 220°C, the pressure reaches 1.6MPa, keep the pressure for 1h, then slowly release the air to normal pressure, raise the temperature to 260°C and keep the reaction for 1h, stop heating, water-cool the strands to discharge, pelletize, and obtain copolymerized nylon pellets.

[0033] Step 2: Prepare nylon copolymer powder by cryogenic crushing. In the crushing process, the crushing temperature in the crushing chamber is controlled at -130±5°C, the rotor clearance is adjusted to 2.0mm, the main engine speed...

Embodiment 3

[0037] Step 1: Add PA1010 salt, PA66 salt, molecular weight regulator, deionized water, and antioxidant into the polymerization kettle. Wherein the mass ratio of PA1010 salt and PA66 salt is 3:7 (according to 10 parts), and the ratio of the mass sum of PA1010 salt and PA66 salt to molecular weight regulator, deionized water and antioxidant mass is 68.8%: 0.6% : 30%: 0.6%; airtight, vacuumize, and then pass through carbon dioxide gas protection 0.18MPa. Raise the temperature to 230°C, the pressure reaches 1.7MPa, keep the pressure for 1.5h, then slowly release the air to normal pressure, raise the temperature to 270°C and keep the reaction for 1.5h, stop heating, water-cool the strips, discharge, pelletize, and obtain copolymerized nylon pellets .

[0038] Step 2: Prepare nylon copolymer powder by cryogenic crushing. In the crushing process, the crushing temperature in the crushing chamber is controlled at -140±5°C, the rotor gap is adjusted to 1.5mm, the main engine speed is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com