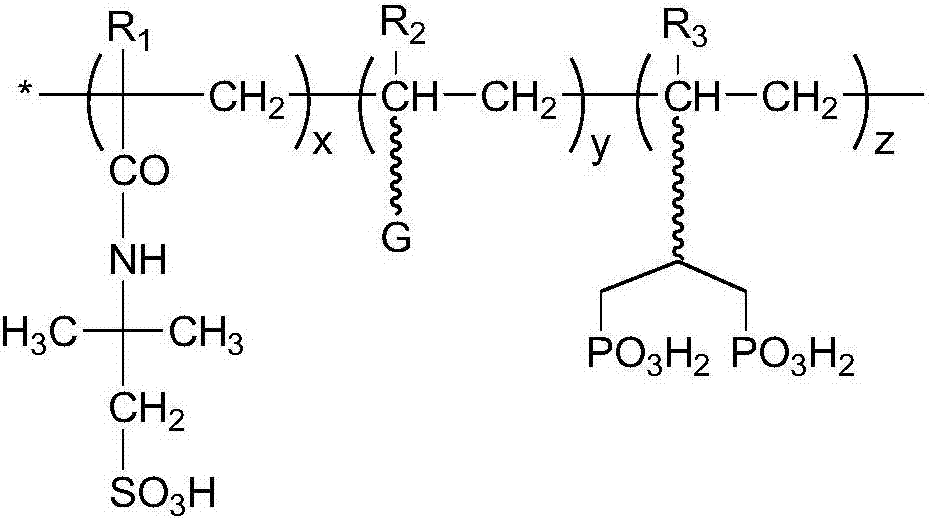

High-temperature-resistant phosphono-containing concrete retarder and preparation method thereof

A retarder and high-temperature-resistant technology, which is applied in the field of high-temperature-resistant phosphonic acid-based concrete retarder and its preparation, can solve complex components of cementitious materials, increased aggregate mud content and water absorption, and lack of stone resources. and other problems, to achieve the effect of improving workability and slump retention ability, improving retarding performance, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

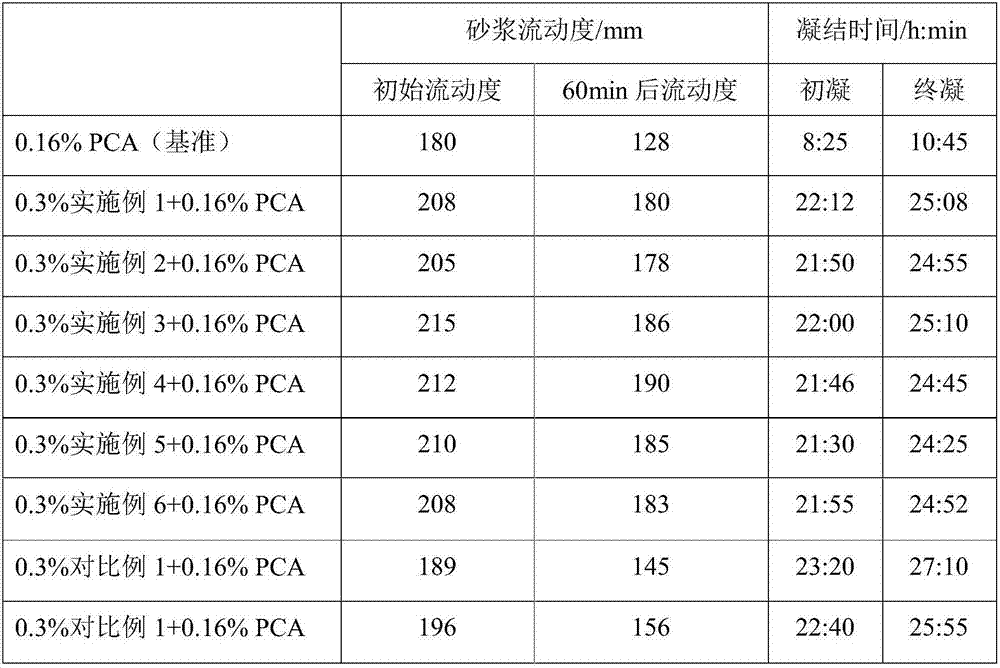

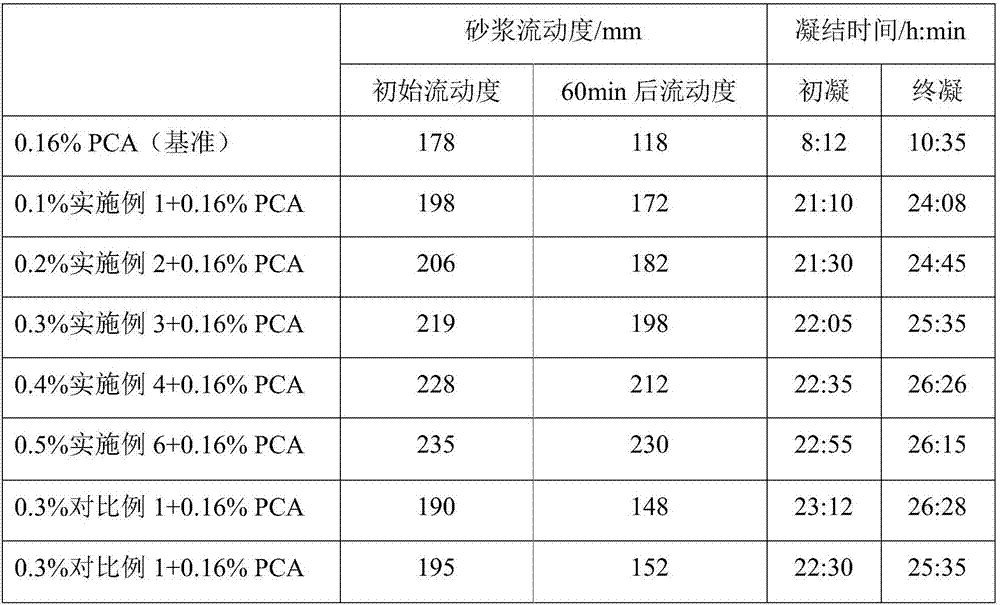

Examples

preparation example Construction

[0058] (1) Preparation of prepolymer

[0059] In a reactor equipped with a thermometer, a stirrer and a dropping device, add 0.1mol methallyl chloride and 5g water, slowly add 0.2mol AMPS and 0.3mol acrylic acid, 0.006g AIBN, 0.006mol mercaptoethanol dropwise Mix solution with 15g of water, under stirring state, heat up to 40°C, add dropwise in 40 minutes, raise the temperature to 50°C, react for 3h, and the corresponding prepolymer can be prepared. Tested by GPC, the molecular weight is 10000, and the molecular weight distribution is 1.35.

[0060] (2) Amination

[0061] Add 0.11 mol of ethylenediamine to the above system, raise the temperature to 90° C., and react for 2 hours to prepare the corresponding aminated product with an organic amine conversion rate of 94%.

[0062] (3) Introduction of phosphate group

[0063] To the above system, add 0.33mol of phosphorous acid, 0.33mol of formaldehyde, a certain amount of sulfuric acid and water, slowly raise the temperature to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com