Preparation method of collagen sponge with recombined fiber structure

A collagen sponge and fiber structure technology, applied in the directions of pharmaceutical formulation, application, medical science, etc., can solve the problems of poor blood effect on collagen sponge, time-consuming dialysis technology, poor hemostatic effect, etc., and achieve the speed of promoting blood coagulation. , Good appearance, the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

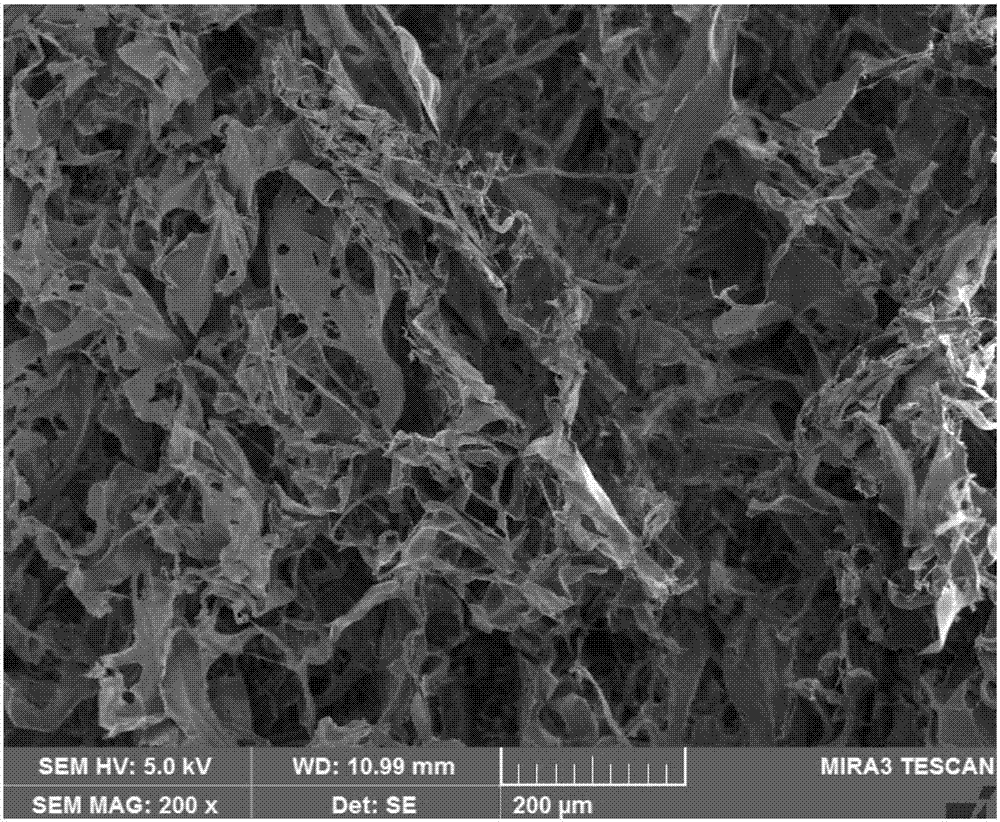

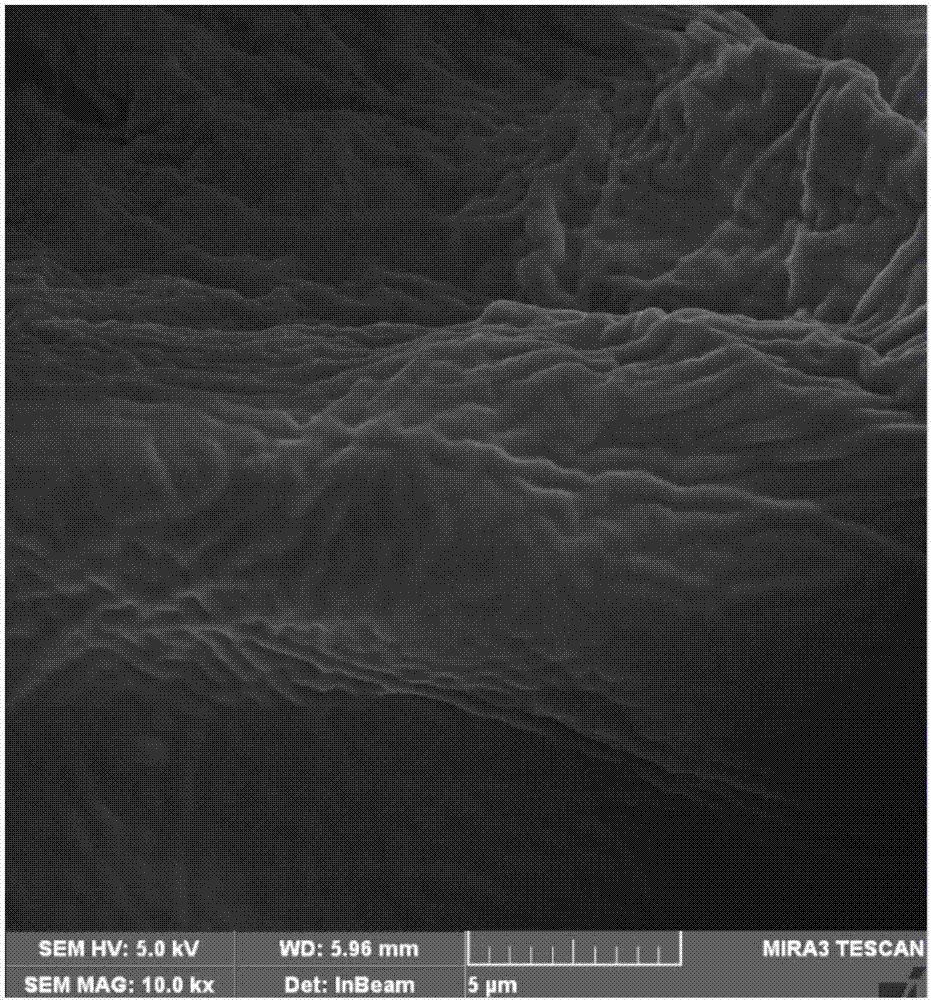

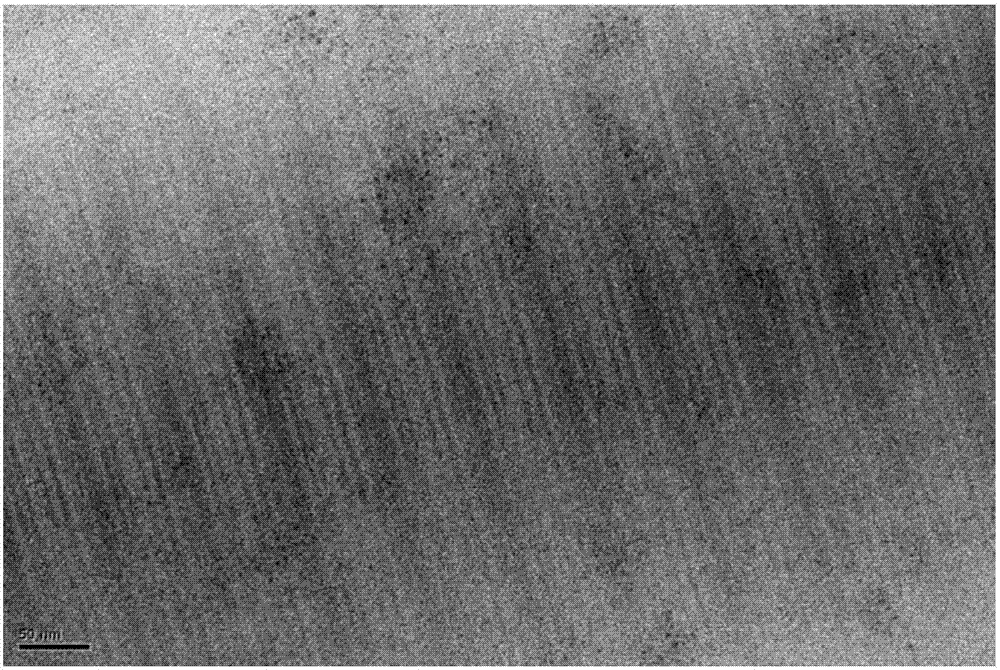

[0067] In this example, the recombined fibrous structure collagen sponge is obtained through the following steps 1-6:

[0068] step 1:

[0069] (1) Re-dissolve the salted-out collagen fibers with acetic acid, and the concentration after re-dissolution is 0.5 mg / mL;

[0070] (2) Using tangential flow filtration technology for collagen:

[0071] a) Purification, the purification solution is 0.01M acetic acid solution, and the molecular weight cut-off of the modified polyethersulfone hollow fiber filter tube is 50KD;

[0072] b) Concentration, this process is carried out at a temperature of 4-13°C, and a modified polyethersulfone hollow fiber filter tube with a pore size of 0.1µm is used for the final collagen concentration;

[0073] Step 2:

[0074] (1) Mix the purified and concentrated collagen solution with a certain volume of biological buffer:

[0075] The concentration of the collagen solution is 1mg / mL, the pH is 2.0; the buffer is 10×PBS, which contains 5ppm glutarald...

specific Embodiment 2

[0081] In this example, the recombined fibrous structure collagen sponge is obtained through the following steps 1-6:

[0082] step 1:

[0083] (1) Redissolve the salted-out collagen fibers with acetic acid, and the concentration after redissolution is 3.5mg / mL;

[0084] (2) Using tangential flow filtration technology for collagen:

[0085] a) Purification, the purification solution is 0.2M acetic acid solution, and the molecular weight cut-off of the modified polyethersulfone hollow fiber filter tube is 70KD;

[0086] b) Concentration, this process is carried out at a temperature of 4-13°C, and a modified polyethersulfone hollow fiber filter tube with a pore size of 0.65µm is used for final collagen concentration;

[0087] Step 2:

[0088] (1) Mix the purified and concentrated collagen solution with a certain volume of biological buffer:

[0089] The concentration of the collagen solution is 3mg / mL, the pH is 3.0; the buffer is 2×TES, which contains 10ppm carbodiimide cro...

specific Embodiment 3

[0095]In this example, the recombined fibrous structure collagen sponge is obtained through the following steps 1-6:

[0096] step 1:

[0097] (1) Re-dissolve the salted-out collagen fibers with acetic acid, and the concentration after re-dissolution is 8 mg / mL;

[0098] (2) Using tangential flow filtration technology for collagen:

[0099] a) Purification, the purification solution is 0.5M acetic acid solution, and the molecular weight cut-off of the modified polyethersulfone hollow fiber filter tube is 100KD;

[0100] b) Concentration, this process is carried out at a temperature of 4-13°C, and a modified polyethersulfone hollow fiber filter tube with a pore size of 1 µm is used for the final collagen concentration;

[0101] Step 2:

[0102] (1) Mix the purified and concentrated collagen solution with a certain volume of biological buffer:

[0103] The concentration of the collagen solution is 5mg / mL, the pH is 3.5; the buffer is 5×HEPES buffered saline solution, which c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com