Method for purification of potassium nitrate in toughened glass waste liquid

A technology of tempered glass and potassium nitrate, applied in the direction of alkali metal nitrate purification, etc., can solve problems such as uneconomical, unenvironmental protection, unfavorable exchange process, etc., and achieve the effect of reducing purification cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Cool the tempered glass waste liquid containing potassium nitrate (concentration is 60% by weight) to room temperature, weigh 90g, add 600ml deionized water, stir at room temperature for 6h to fully dissolve, and filter to obtain solid impurity removed solution.

[0054] (2) Add 10 g of potassium carbonate and 10 g of potassium sulfate to 80 g of the solution, stir at 60° C. for 6 h to fully dissolve, and then perform solid-liquid separation.

[0055] The total content of calcium, magnesium, barium and strontium elements in the solution measured by an ICP spectrometer was 0.13% by weight.

[0056] Repeat the operation, add potassium carbonate, potassium sulfate and carry out solid-liquid separation, and measure the total content of calcium, magnesium, barium and strontium elements in the solution according to the aforementioned method to be 0.09% by weight.

[0057] Repeat the operation again, add potassium carbonate, potassium sulfate and carry out solid-liquid se...

Embodiment 2

[0072] (1) Cool the tempered glass waste liquid containing potassium nitrate (concentration is 95% by weight) to room temperature, weigh 80g, add 500ml deionized water, stir at room temperature for 5h to fully dissolve, and filter to obtain solid impurity removed solution.

[0073] (2) Add 8 g of potassium carbonate and 8 g of potassium sulfate to 70 g of the solution, stir at 50° C. for 5 h to fully dissolve, and then perform solid-liquid separation.

[0074] Repeat operation, add potassium carbonate, potassium sulfate and carry out solid-liquid separation altogether 5 times, record the total content of calcium, magnesium, barium and strontium element in the described solution according to the method of embodiment 1 and be 0.009% by weight, obtain clear solution .

[0075] (3) The clarified solution is fully contacted with the zeolite molecular sieve at a temperature of 60° C., and then impurities are removed.

[0076] The operation was repeated, and ion exchange and filtra...

Embodiment 3

[0082] (1) Cool the tempered glass waste liquid containing potassium nitrate (concentration is 75% by weight) to room temperature, weigh 70g, add 100ml deionized water, stir at room temperature for 5h to fully dissolve, and filter to obtain solid impurity removed solution.

[0083] (2) 60 g of the solution was added with 6 g of potassium carbonate and 6 g of potassium sulfate, stirred at 70° C. for 5 h to fully dissolve, and then separated into solid and liquid.

[0084] Repeat operation, add potassium carbonate, potassium sulfate and carry out solid-liquid separation altogether 4 times, record the total content of calcium, magnesium, barium and strontium element in the described solution according to the method of embodiment 1 and be 0.013% by weight, obtain clear solution .

[0085] (3) The clarified solution is fully contacted with the zeolite molecular sieve at a temperature of 50° C., and then impurities are removed.

[0086] The operation was repeated, and ion exchange...

PUM

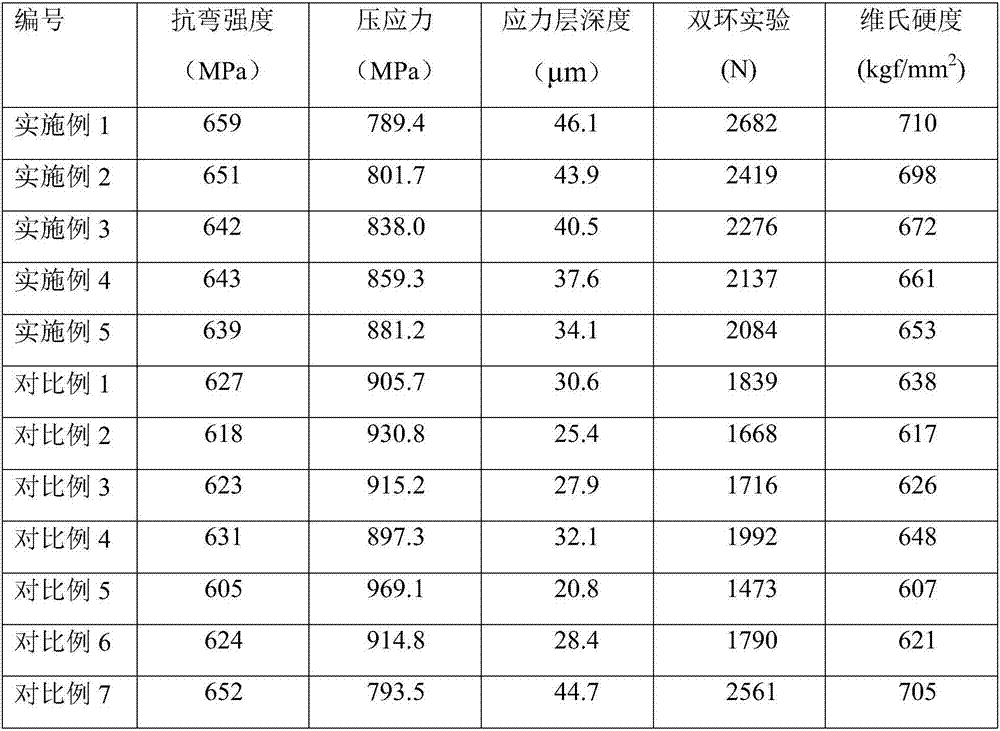

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Compressive stress | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com