Preparation method of self-cooled and hole-closing-resistant lithium ion battery diaphragm

A lithium-ion battery, self-cooling technology, applied in the field of lithium-ion battery diaphragm preparation, can solve the problems of lithium battery scrapping, economic loss, permanent closed cells, etc., to achieve the effect of improving anti-corrosion performance, improving tissue performance, and delaying closed cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

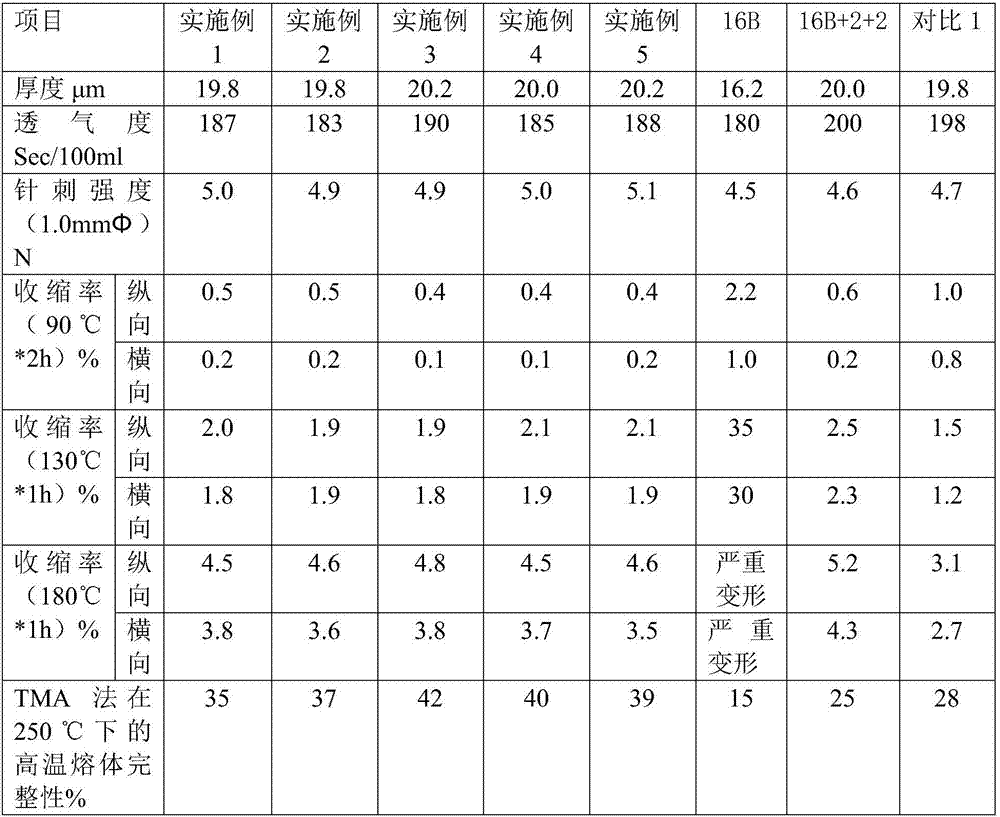

Examples

Embodiment 1

[0029] (1), preparation of erythritol modified ceramic slurry

[0030] Add deionized water and sodium polyacrylate to the planetary mixer, then add ammonia water to adjust the pH value, and adjust the pH value to between 7.5-8.5, preferably 8. The amount of dispersant added is 1% of the weight of the primary mixed slurry 3%, followed by stirring and ultrasonic vibration at the same time, the stirring speed is 1200r / min, and it lasts for 1h. The tank of the planetary mixer is a multi-blade stirring paddle, which also rotates while revolving, so that the material flows up and down and around. Therefore, the mixing effect can be achieved in a short time. The inner wall of the tank is finished by a large vertical lathe, and then automatically polished by a large polishing machine to ensure that the movable scraper on the planetary carrier completely scrapes off the material on the inner wall of the tank when rotating. The planetary mixer is equipped with an input-type ultrasonic v...

Embodiment 2

[0043] (1), preparation of erythritol modified ceramic slurry

[0044] Add deionized water, sodium polymetaphosphate, and sodium silicate to a planetary mixer equipped with a drop-in ultrasonic vibration plate, and the dispersant accounts for 1% of the total weight of the first-stage mixed slurry, followed by stirring and ultrasonic vibration at the same time, Form a primary mixed slurry;

[0045] Add ceramic powder with a median particle size of 0.5-0.7 μm to the primary mixing slurry, and the proportion of ceramic powder is 10% of the total weight of the secondary mixing slurry, followed by stirring and ultrasonic vibration at the same time to form a secondary mixing slurry;

[0046] Add erythritol to the secondary mixed slurry, the addition amount is 10% of the weight of the secondary mixed slurry (the total amount should not be too low, otherwise it will affect the heat absorption during phase transition), and then stir and ultrasonic Vibrate to form a three-stage mixed ...

Embodiment 3

[0052] (1), preparation of erythritol modified ceramic slurry

[0053] Add deionized water and sodium lauryl sulfate to a planetary mixer equipped with a drop-in ultrasonic vibrating plate, and the dispersant accounts for 2% of the total weight of the primary mixed slurry, followed by simultaneous stirring and ultrasonic vibration to form a Grade mixed slurry;

[0054] Add ceramic powder with a median particle size of 0.7-0.9 μm to the primary mixing slurry, and the proportion of ceramic powder is 20% of the total weight of the secondary mixing slurry, followed by stirring and ultrasonic vibration at the same time to form a secondary mixing slurry;

[0055] Adding erythritol to the secondary mixed slurry in an amount of 15% of the weight of the secondary mixed slurry, followed by simultaneous stirring and ultrasonic vibration to form a tertiary mixed slurry;

[0056] D, add aqueous acrylic latex and sodium carboxymethyl cellulose solution in the three-stage mixed slurry, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com