Method for preparing pyrolytic boron nitride material

A boron nitride and pyrolysis technology is applied in the field of preparation of pyrolysis boron nitride materials, which can solve the problems of difficult process control, high requirements on production equipment, personnel, environmental hazards and process stability, and achieves the improvement of ceramic output. efficiency and production efficiency, improving process controllability and stability, simplifying process parameters and the effect of experimental equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

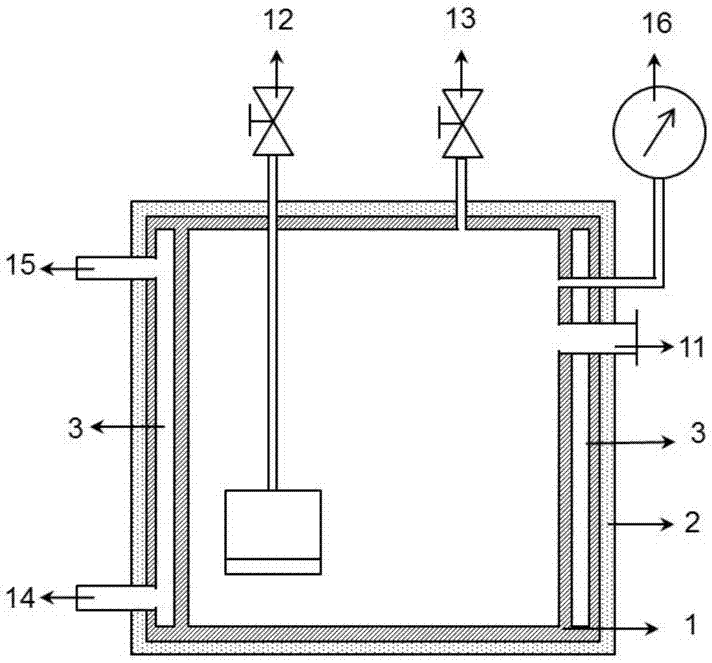

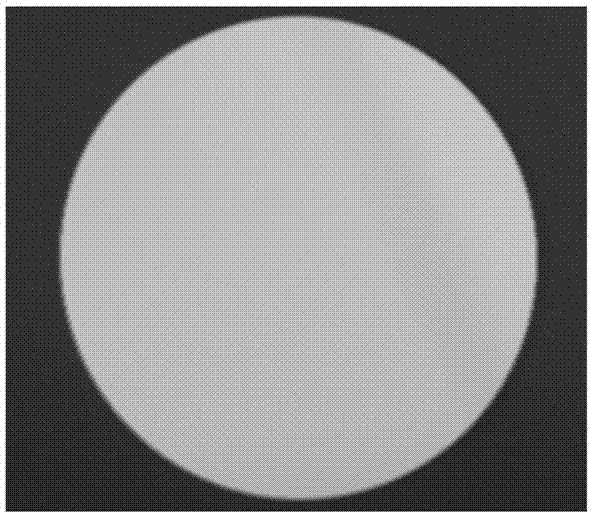

[0032] A preparation method of pyrolytic boron nitride material of the present invention, comprising the following steps:

[0033] (1) Preparation of the deposition base mold: Use a high-purity graphite disc with a diameter of 100 mm and a thickness of 5 mm as the base mold material. After the deposition surface is polished, it is cleaned ultrasonically in absolute ethanol to remove graphite dust and impurities on the deposition surface. After drying, it is installed and fixed on the rotary stage in the chemical vapor deposition furnace, so that the surface to be deposited faces the direction of the source of the deposition gas; wherein, the material of the high-purity graphite disc is hot isostatic graphite with a density of 1.83g / cm 3 , porosity 10%, thermal expansion coefficient 4.2×10 -6 K -1 .

[0034] (2) Vacuumize to 1 Pa in the chemical vapor deposition furnace, raise the temperature to 1150°C at a rate of 15°C / min, keep it for 60 minutes, and then continue to hea...

Embodiment 2

[0042] A preparation method of pyrolytic boron nitride material of the present invention, comprising the following steps:

[0043] (1) Preparation of the deposition base mold: Use a high-purity graphite disc with a diameter of 100 mm and a thickness of 5 mm as the base mold material. After the deposition surface is polished, it is cleaned ultrasonically in absolute ethanol to remove graphite dust and impurities on the deposition surface. After drying, it is installed and fixed on the rotary stage in the chemical vapor deposition furnace, so that the surface to be deposited faces the direction of the source of the deposition gas; wherein, the material of the high-purity graphite disc is hot isostatic graphite with a density of 1.83g / cm 3 , porosity 10%, thermal expansion coefficient 4.2×10 -6 K -1 .

[0044] (2) Vacuumize to 1 Pa in the chemical vapor deposition furnace, raise the temperature to 1150°C at a rate of 10°C / min, keep it for 30 minutes, and then continue to hea...

Embodiment 3

[0049] A preparation method of pyrolytic boron nitride material of the present invention, comprising the following steps:

[0050] (1) Preparation of the deposition base mold: Use a high-purity graphite square sheet with a length × width of 150 × 50 mm and a thickness of 5 mm as the base mold material. After the deposition surface is polished and polished, it is ultrasonically cleaned in absolute ethanol to remove the deposition surface. Graphite dust and impurities, after drying, are installed and fixed on the rotary stage in the chemical vapor deposition furnace, so that the surface to be deposited faces the direction of the source of the deposition gas; the material of the high-purity graphite disc is hot isostatic pressing Graphite, density 1.83g / cm 3 , porosity 10%, thermal expansion coefficient 4.2×10 -6 K -1 .

[0051] (2) Vacuumize to 1 Pa in the chemical vapor deposition furnace, raise the temperature to 1150°C at a rate of 12°C / min, keep it for 60 minutes, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com