Biomass charcoal

A technology of biochar and stipa, applied in the field of straw application, can solve the problems of straw pollution, waste of biomass resources, pollution of the environment, etc., and achieve the effect of improving the material structure, promoting nutrient transfer, and increasing the formation of micropores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

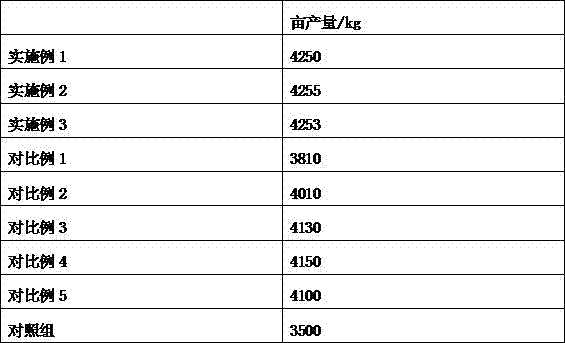

Examples

Embodiment 1

[0016] A kind of biochar, which is made by mixing corn stalks, wheat straw, cotton stalks and stipa; specifically: mixing corn stalks, wheat stalks, cotton stalks and stipa in a mass ratio of 8:6:5:1 Dry at 100°C, and then pulverize to obtain mixed powder. The mixed powder is treated with low-temperature plasma, and then added to the pyrolysis furnace, and argon gas is introduced to remove the oxygen in the pyrolysis furnace. The temperature is rapidly heated to 102°C, kept for 5 minutes, then raised to 360°C at a rate of 1°C / min, kept at a temperature of 20 minutes, then raised to 580-586°C at a rate of 2°C / min, carried out multi-stage heat preservation, and finally cooled naturally To room temperature, collect biochar, and that's it.

[0017] Said drying at 100°C, specifically until the total moisture content is lower than 1.5%, and the drying time is longer than 1 hour.

[0018] The crushing process is specifically crushed to a particle size of 20 mesh.

[0019] The low-t...

Embodiment 2

[0025] A kind of biochar, which is made by mixing corn stalks, wheat straws, cotton stalks and stipa; specifically: mixing corn stalks, wheat stalks, cotton stalks and stiga in a mass ratio of 10: 8: 8: 2 Dry at 102°C, and then pulverize to obtain mixed powder, which is treated with low-temperature plasma, then added to the pyrolysis furnace, and argon gas is introduced to remove the oxygen in the pyrolysis furnace. The temperature is rapidly heated to 105°C, kept for 5-8 minutes, then raised to 364°C at a rate of 1°C / min, kept at a temperature of 25 minutes, and then raised to 580-586°C at a rate of 2°C / min. Naturally cool to room temperature and collect biochar.

[0026] Said drying at 102°C, specifically until the total water content is lower than 1.5%, and the drying time is longer than 1 hour.

[0027] The crushing process is specifically crushed to a particle size of 30 mesh.

[0028] The low-temperature plasma treatment specifically includes: adding the mixed powder i...

Embodiment 3

[0034] A kind of biochar, which is made by mixing corn stalks, wheat straw, cotton stalks and stipa; specifically: mixing corn stalks, wheat stalks, cotton stalks and stipa in a mass ratio of 9:7:6:1.5 Dry at 101°C, and then pulverize to obtain mixed powder. Treat the mixed powder with low-temperature plasma, then add it to the pyrolysis furnace, pass in argon gas, and remove the oxygen in the pyrolysis furnace. The temperature is rapidly heated to 103°C, held for 6 minutes, then raised to 362°C at a rate of 1°C / min, held for 22 minutes, and then raised to 580-586°C at a rate of 2°C / min, carried out multi-stage heat preservation, and finally cooled naturally To room temperature, collect biochar, and that's it.

[0035] Said drying at 101°C, specifically until the total water content is lower than 1.5%, and the drying time is greater than 1 hour.

[0036] The crushing process is specifically crushed to a particle size of 25 mesh.

[0037] The low-temperature plasma treatment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com