Epoxy cured polyester resin used for powdery paint having high surface decorative performance and high water resistance and preparation method thereof

A powder coating and polyester resin technology, applied in the field of polyester resin, can solve the problems of reducing the chemical storage stability of powder coatings, reducing the surface decoration performance of powder coatings, poor water resistance of powder coatings, etc., achieving excellent dynamic mechanical properties, Excellent color and high water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

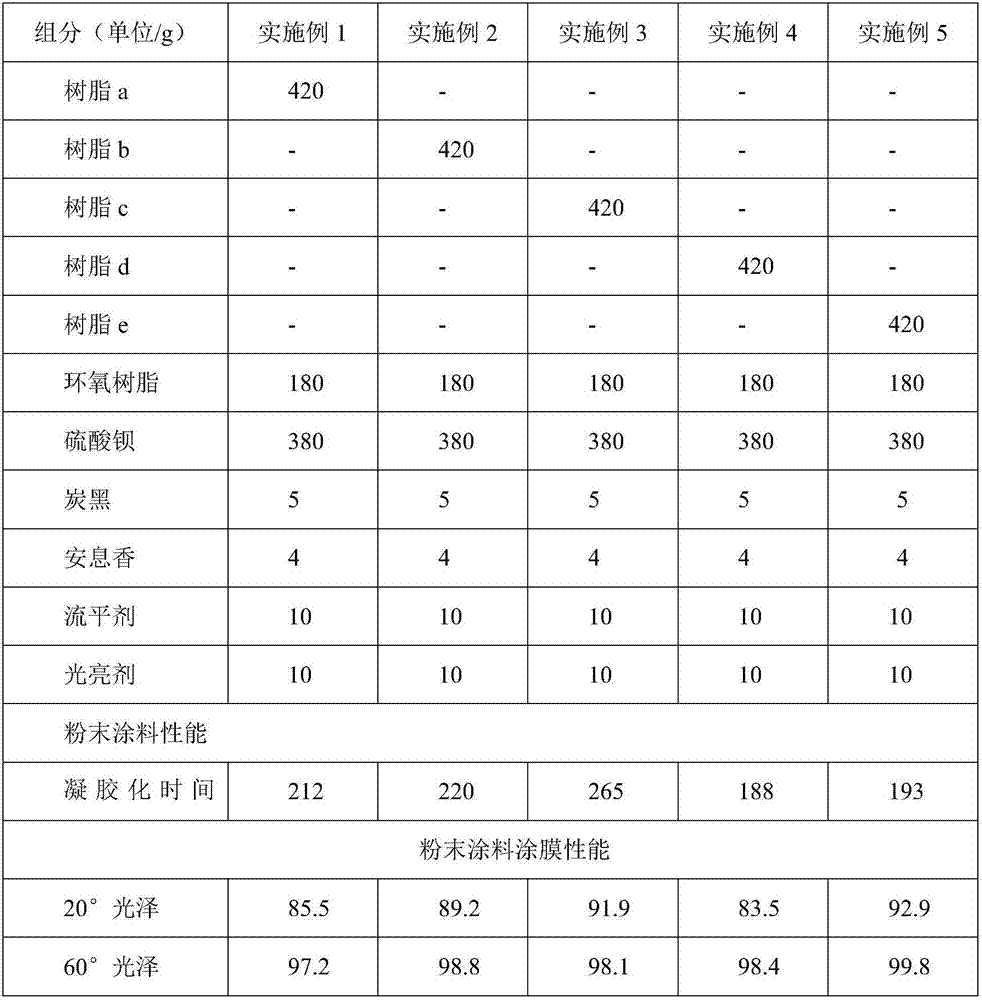

Examples

Embodiment a

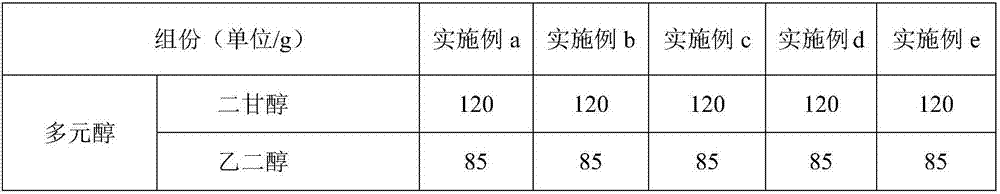

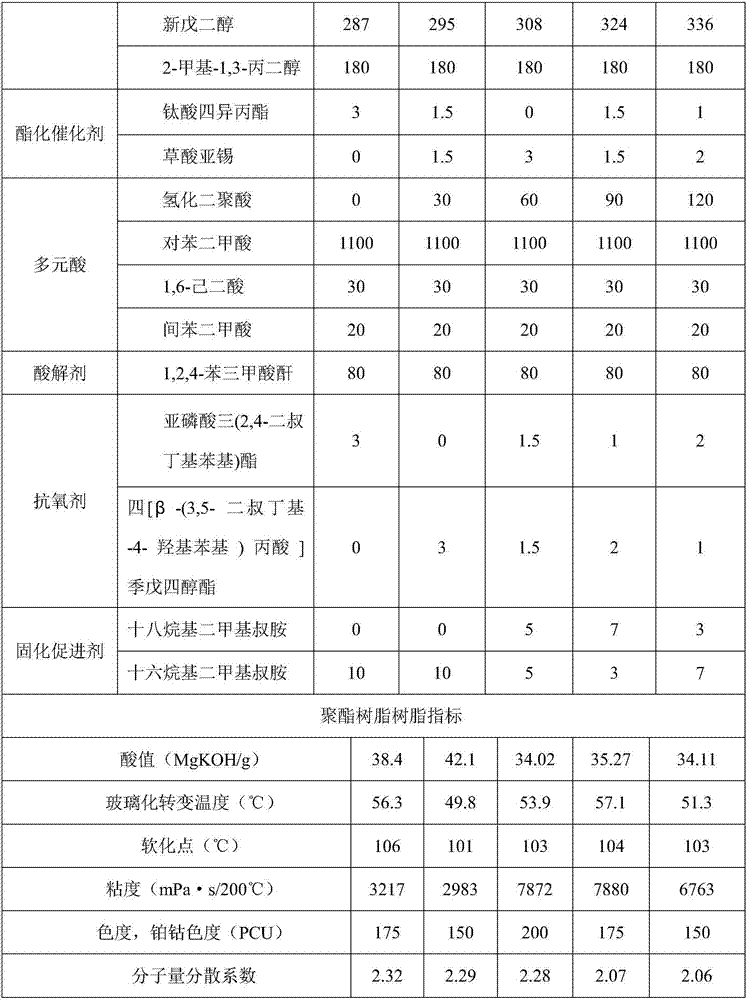

[0041] In a 3000ml four-neck flask equipped with a stirrer, condenser, thermometer and nitrogen protection, add 120 parts of diethylene glycol, 85 parts of ethylene glycol, 287 parts of neopentyl glycol, 180 parts of 2-methyl Base 1,3-propanediol, 3 parts of tetraisopropyl titanate, 1100 parts of terephthalic acid, 30 parts of 1,6-adipic acid, 20 parts of isophthalic acid, nitrogen protection; when the temperature rises At 160°C, esterification water begins to flow out; continue to heat up to 250°C, and when the amount of esterification water reaches 95% of the theoretical value, take a sample and test, and the acid value reaches 18.0-24.0mgKOH / g; add polyacid end-capping agent 1 , 80 parts of 2,4-benzenetricarboxylic anhydride, heat preservation and reaction at 240°C-250°C for 40-50 minutes; after the reaction was completed, the acid value reached 46.0-52.0mgKOH / g, at -0.113~-0.095MPa Negative compression polymerization for 1 hour, negative compression polymerization at -0.09...

Embodiment b

[0043] In a 3000ml four-neck flask equipped with a stirrer, condenser, thermometer and nitrogen protection, add 120 parts of diethylene glycol, 85 parts of ethylene glycol, 295 parts of neopentyl glycol, 180 parts of 2-methyl 1,3-propanediol, 1.5 parts of tetraisopropyl titanate, 1.5 parts of stannous oxalate, 30 parts of hydrogenated dimer acid, 1100 parts of terephthalic acid, 30 parts of 1,6-adipic acid , 20 parts of isophthalic acid, filled with nitrogen for protection; when the temperature rises to 160°C, esterification water begins to flow out; when the temperature continues to rise to 250°C, when the amount of esterification water effluent reaches 95% of the theoretical value, sampling and testing, the acid value Reach 18.0-24.0mgKOH / g; add 80 parts of polybasic acid end-capping agent 1,2,4-benzenetricarboxylic anhydride, keep warm and react for 40-50 minutes at 240℃~250℃; Reach 46.0~52.0mgKOH / g, polymerize under negative compression at -0.113~-0.095MPa for 1 hour, and ...

Embodiment c

[0045] In a 3000ml four-neck flask equipped with a stirrer, condenser, thermometer and nitrogen protection, add 120 parts of diethylene glycol, 85 parts of ethylene glycol, 308 parts of neopentyl glycol, 180 parts of 2-methyl 1,3-propanediol, 3 parts of stannous oxalate, 60 parts of hydrogenated dimer acid, 1100 parts of terephthalic acid, 30 parts of 1,6-adipic acid, 20 parts of isophthalic acid, full Nitrogen protection; when the temperature rises to 160°C, esterification water begins to flow; when the temperature continues to rise to 250°C, when the amount of esterification water reaches 95% of the theoretical value, sampling and testing shows that the acid value reaches 18.0-24.0mgKOH / g; add multi-component 80 parts of acid-blocking agent 1,2,4-benzenetricarboxylic anhydride, heat preservation reaction at 240°C-250°C for 40-50 minutes; Negative compression polymerization at 0.113~-0.095MPa for 1 hour, negative compression polymerization at -0.095~-0.099MPa for 1 hour; cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com