a punch punch

A punching and punching technology, applied in the field of punching parts, can solve the problems of poor wear resistance, strength and corrosion resistance, increase the labor intensity of operators, and keep the overall cost high, and achieve high hardness and high temperature resistance. The effect of improving layer strength and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

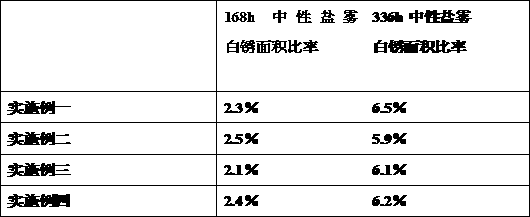

Examples

Embodiment 1

[0023] A punch rod for a punching machine and a manufacturing method thereof, comprising a punch rod body and a surfacing layer on the punching operation end face of the punch rod body, and a laser shock layer is provided on the punch rod body surface except for the punch rod body stamping operation end face,

[0024] The punch rod manufacturing method includes the following steps: adding copper alloy smelting raw materials into the melting furnace, controlling the furnace temperature at 1140°C, after the raw materials are completely melted, the temperature drops to 1040°C, adding a deoxidizer, and the deoxidizer is fully mixed with the melt After that, let it stand for 5-10 minutes, add covering agent, and let it stand for 10-15 minutes; remove the slag, lower the temperature to 1020-1030°C, stir and add refining agent, the amount of refining agent added is 8- 10kg, the refining agent includes the following components by weight: 54 parts of calcium fluoride, 12 parts of calciu...

Embodiment 2

[0028] A punch rod for a punching machine and a manufacturing method thereof, comprising a punch rod body and a surfacing layer on the punching operation end face of the punch rod body, and a laser shock layer is provided on the punch rod body surface except for the punch rod body stamping operation end face,

[0029]The punch rod manufacturing method includes the following steps: adding copper alloy smelting raw materials into the melting furnace, controlling the furnace temperature at 1135°C, after the raw materials are completely melted, the temperature drops to 1050°C, adding a deoxidizer, and the deoxidizer is fully mixed with the melt After that, let it stand for 5-10 minutes, add covering agent, and let it stand for 10-15 minutes; remove the slag, lower the temperature to 1020-1030°C, stir and add refining agent, the amount of refining agent added is 8- 10kg, the refining agent comprises the following components by weight: 60 parts of calcium fluoride, 15 parts of calciu...

Embodiment 3

[0033] A punch rod for a punching machine and a manufacturing method thereof, comprising a punch rod body and a surfacing layer on the punching operation end face of the punch rod body, and a laser shock layer is provided on the punch rod body surface except for the punch rod body stamping operation end face,

[0034] The punch rod manufacturing method includes the following steps: adding copper alloy smelting raw materials into the melting furnace, controlling the furnace temperature at 1130°C, after the raw materials are completely melted, the temperature drops to 1055°C, adding a deoxidizer, and the deoxidizer is fully mixed with the melt After that, let it stand for 5-10 minutes, add covering agent, and let it stand for 10-15 minutes; remove the slag, lower the temperature to 1020-1030°C, stir and add refining agent, the amount of refining agent added is 8- 10kg, the refining agent comprises the following components by weight: 70 parts of calcium fluoride, 15 parts of calci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com