A kind of anti-ultraviolet softening agent for textiles, preparation method and application thereof

A softening finishing agent, anti-ultraviolet technology, used in textiles and papermaking, fiber processing, improved hand-feeling fibers, etc., can solve the problems of increasing the reflection and scattering effect on the surface of the fabric, the textile feels hard, and the air permeability is poor. The effect of UV performance, fewer process steps, and lower cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

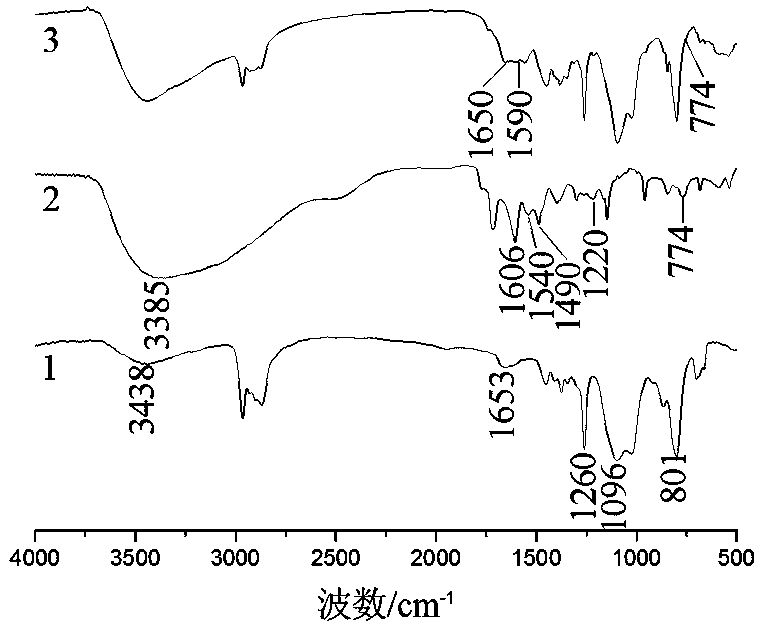

Image

Examples

Embodiment 1

[0028] 1. Add 11.78g of methyl hydrogen-containing silicone oil, 0.78g of acrylamide and 12.00g of allyl polyoxyethylene polyoxypropylene ether into a reaction vessel equipped with a stirrer, a thermometer and a condensing reflux tube, and stir. After heating until the solid is completely dissolved, add 0.60 g of chloroplatinic acid solution, and raise the temperature to 90°C under the protection of nitrogen. After reacting for 4 hours, remove low boilers under reduced pressure, cool the product to room temperature, and use 29.50 g of methanol-acetone The mixed solvent (the volume ratio of methanol to acetone is 5:1) is fully washed, the mixed solvent is removed under reduced pressure, and the obtained product is vacuum-dried at 78-82°C to obtain intermediate I.

[0029] 2. Add 3.00g of cyanuric chloride to a reaction vessel equipped with a stirrer, a thermometer and a condensation reflux device, weigh 8.00g of chlorobenzene as a solvent, stir until the solid is completely diss...

Embodiment 2

[0036] 1. Add 11.78g of methyl hydrogen-containing silicone oil, 0.85g of acrylamide and 13.50g of allyl polyoxyethylene polyoxypropylene ether into a reaction vessel equipped with a stirrer, a thermometer and a condensing reflux tube, and stir. After heating until the solid is completely dissolved, add 0.70g of chloroplatinic acid solution, under the protection of nitrogen, raise the temperature to 95°C, react for 4.5h, remove low boilers under reduced pressure, cool the product to room temperature, and use 34.00g of methanol- Acetone mixed solvent (the volume ratio of methanol to acetone is 5:1) is fully washed, the mixed solvent is removed under reduced pressure, and the obtained product is vacuum-dried at 78-82°C to obtain intermediate I.

[0037] 2. Add 3.00g of cyanuric chloride to a reaction vessel equipped with a stirrer, a thermometer and a condensation reflux device, weigh 9.70g of chlorobenzene as a solvent, stir until the solid is completely dissolved, and add 2.40g...

Embodiment 3

[0044] 1. Add 11.78g of methyl hydrogen-containing silicone oil, 0.92g of acrylamide and 15.00g of allyl polyoxyethylene polyoxypropylene ether into a reaction vessel equipped with a stirrer, a thermometer and a condensing reflux tube, and stir. After heating until the solid is completely dissolved, add 0.79g of chloroplatinic acid solution, under the protection of nitrogen, raise the temperature to 100°C, after reacting for 5h, remove low boilers under reduced pressure, cool the product to room temperature, and use 38.00g of methanol-acetone The mixed solvent (the volume ratio of methanol to acetone is 5:1) is fully washed, the mixed solvent is removed under reduced pressure, and the obtained product is vacuum-dried at 78-82°C to obtain intermediate I.

[0045] 2. Add 3.00g of cyanuric chloride to a reaction vessel equipped with a stirrer, a thermometer and a condensation reflux device, weigh 11.70g of chlorobenzene as a solvent, stir until the solid is completely dissolved, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com