A way to improve mn 4+ Method for Humidity Resistance of Doped Fluoride Red Phosphor Powder Material

A technology of red phosphor and fluoride, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of affecting the service life and instability of white LEDs, and achieve the effect of not easy to hydrolyze, improve moisture resistance, and simple and easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] (1)A 2 MnF 6 Preparation of fluoromanganate

[0044] press A 2 MnF 6 The stoichiometric ratio of fluoromanganate is to dissolve the fluoride of A or the hydrogen fluoride of A in a hydrofluoric acid solution with a mass concentration of 49%, and add KMnO 4 , after completely dissolving, cool to below 5°C, add hydrogen peroxide solution with a mass concentration of 30.00% drop by drop until the solution turns from purple to yellow, then stop immediately, let stand, precipitate, filter, and pass the obtained yellow precipitate through acetone Wash and dry at 80°C for 2h to obtain A 2 MnF 6 Fluoromanganate;

[0045] (2) Mn 4+ Preparation of Fluoride-doped Red Phosphor

[0046] According to the Mn 4+ For the stoichiometric ratio of doped fluoride red phosphor, take the compound containing M or T element (the oxide, acid or salt of M or T element) and dissolve it in a hydrofluoric acid solution with a mass concentration of 0-60%. rejoin A 2 MnF 6 Fluoromanganate,...

Embodiment 1

[0052] K 2 TiF 6 :Mn 4+ The preparation of fluoride red fluorescent powder specifically comprises the following steps:

[0053] press K 2 TiF 6 :Mn 4+ Stoichiometric ratio, weigh 0.490ml H 2 TiF 6 Dissolve in 5ml of distilled water, add 0.062g of potassium hexafluoromanganate and react for 10 minutes; then add 0.581g of potassium fluoride and continue to stir for 30 minutes; let stand, precipitate, filter to remove the supernatant, and wash the obtained precipitate with absolute ethanol 3 times , and finally dry it in a 70°C drying oven for 2 hours, and the obtained orange-yellow powder is the final product K 2 TiF 6 :Mn 4+ Fluoride red phosphor.

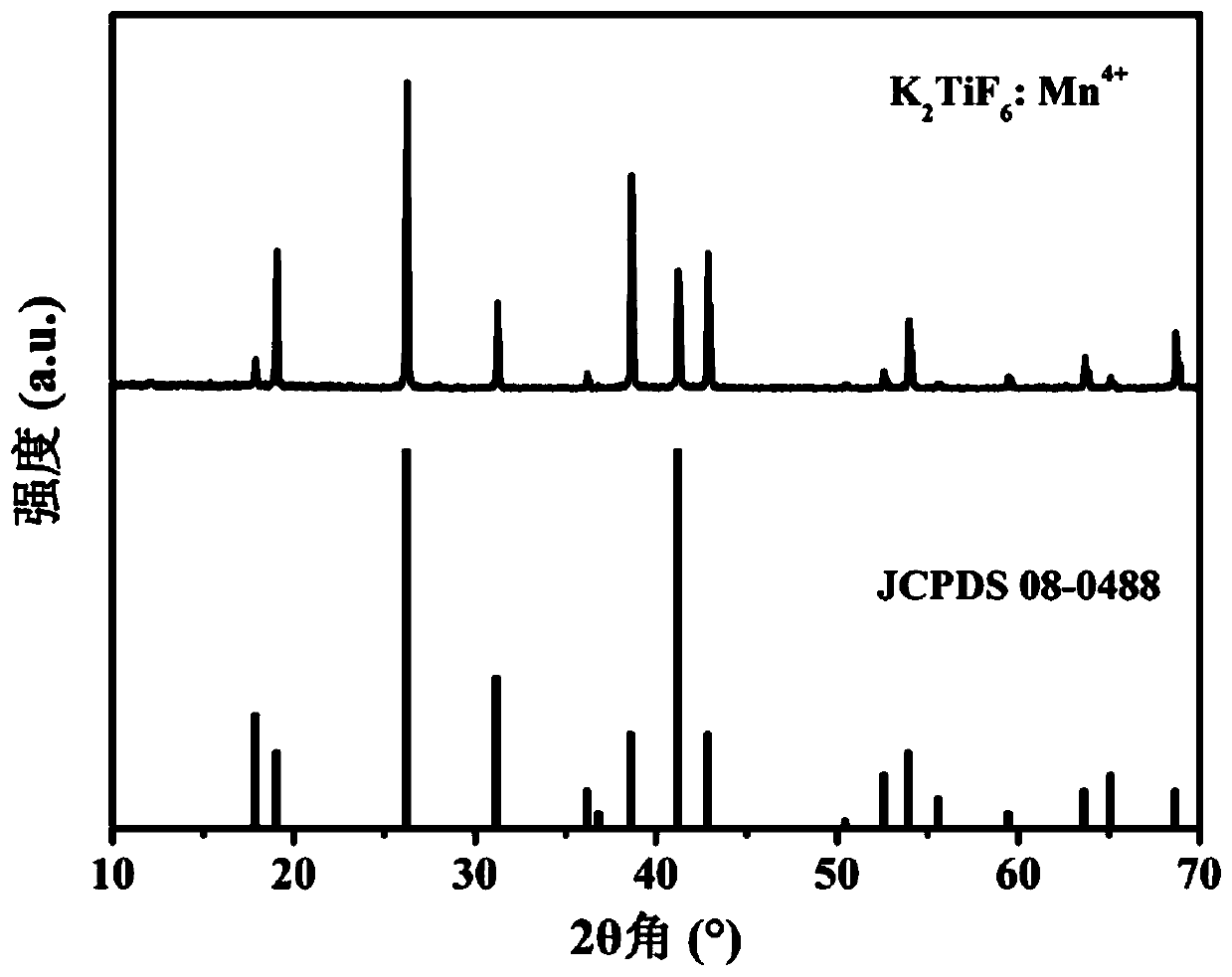

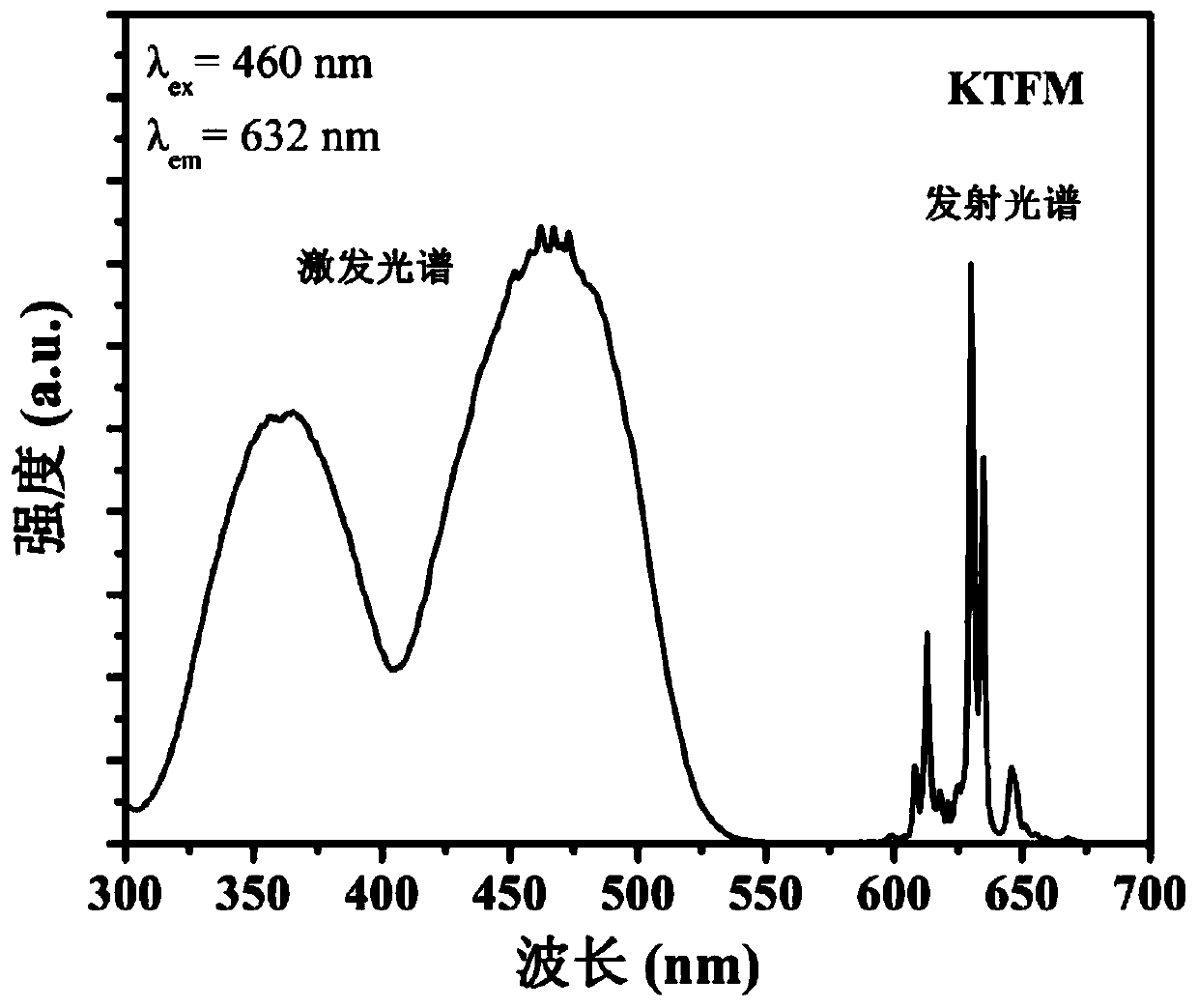

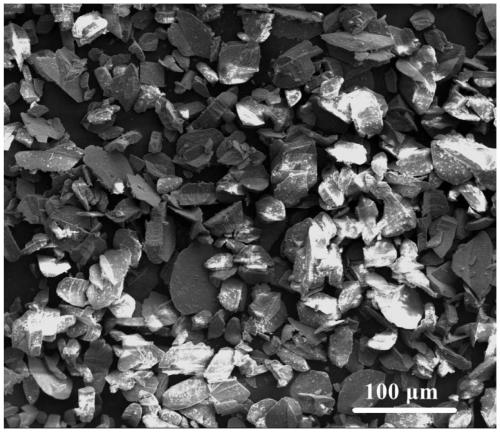

[0054] Prepared sample K 2 TiF 6 :Mn 4+ The XRD diffraction pattern of the red phosphor is as follows figure 1 shown by figure 1 It can be seen that the diffraction peak of the sample is consistent with the standard card JCPDS 08-0488 (K 2 TiF 6 ) are completely consistent, and no diffraction peaks of any heterogene...

Embodiment 2

[0058] K 2 TiF 6 :Mn 4+ The preparation of fluoride red fluorescent powder and the improvement of moisture resistance performance specifically include the following steps:

[0059] press K 2 TiF 6 :Mn 4+ Stoichiometric ratio, weigh 0.40g TiO 2 Dissolve in 5ml hydrofluoric acid solution (49 wt%), stir at room temperature for 60min until completely dissolved, add 0.124g potassium hexafluoromanganate, react for 10 minutes; then add 1.16g potassium fluoride and continue stirring for 30min; stand still, precipitate , filtered to remove the supernatant, the resulting precipitate was washed 3 times with absolute ethanol, and finally dried in an oven at 80°C for 4 hours, and the obtained orange-yellow powder was the final product K 2 TiF 6 :Mn 4+ Fluoride red phosphor.

[0060] K 2 TiF 6 :Mn 4+ Fluoride red fluorescent powder is placed in ethanol solution containing 20wt% hydrogen peroxide and stirred for 1h, and the K with improved moisture resistance is obtained through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com