High-temperature-resistant radiation protective paint for electronic products

A technology for anti-radiation coatings and electronic products. It is applied in the field of anti-radiation coatings. It can solve the problems of poor high-temperature resistance and adhesion of coatings, unsatisfactory coating film effects, and low aesthetics of coatings. Good wave-absorbing and radiation-proof performance, the effect of protecting the health of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

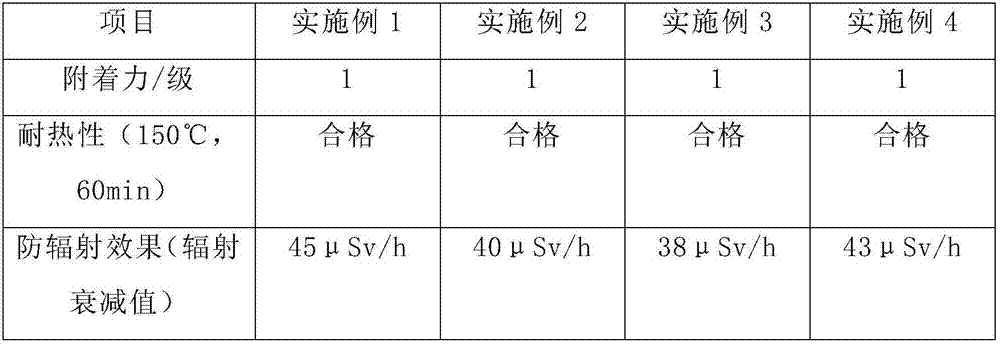

Examples

Embodiment 1

[0017] A high-temperature-resistant radiation-resistant coating for electronic products, which is composed of high-temperature-resistant slurry and wave-absorbing radiation-proof material. The components of the high-temperature-resistant slurry are: 70 parts by mass of ethanol, 10 parts of ether, 8 parts of iron powder, 10 parts of ferrosilicon powder, 8 parts of ferronickel powder, 4 parts of copper powder, 4 parts of nitrocellulose, 15 parts of potassium silicate, 10 parts of butyl acetate; the composition of the wave-absorbing and radiation-proof material is: disulfide 4 parts of molybdenum, 8 parts of graphene oxide, 11 parts of silicon carbide, 2 parts of nano-alumina, 4 parts of titanium dioxide, 10 parts of lithium silicate, 60 parts of deionized water.

[0018] Among them, the preparation method of the high-temperature-resistant slurry is: according to the mass parts, ethanol, ether and butyl acetate are mixed to obtain an organic solvent, and then iron powder, sendust ...

Embodiment 2

[0022] A high-temperature-resistant radiation-resistant coating for electronic products, which is composed of high-temperature-resistant slurry and wave-absorbing radiation-proof material. The components of the high-temperature-resistant slurry are: 80 parts by mass of ethanol, 15 parts of ether, 15 parts of 15 parts of ferrosilicon powder, 10 parts of ferronickel powder, 6 parts of copper powder, 8 parts of nitrocellulose, 20 parts of potassium silicate, 15 parts of butyl acetate; the composition of the wave-absorbing and radiation-proof material is: disulfide 5 parts of molybdenum, 12 parts of graphene oxide, 15 parts of silicon carbide, 10 parts of nano-alumina, 6 parts of titanium dioxide, 15 parts of lithium silicate, 70 parts of deionized water.

[0023] Among them, the preparation method of the high-temperature-resistant slurry is: according to the mass parts, ethanol, ether and butyl acetate are mixed to obtain an organic solvent, and then iron powder, sendust powder, n...

Embodiment 3

[0027] A high-temperature-resistant radiation-resistant coating for electronic products, which is composed of high-temperature-resistant slurry and wave-absorbing radiation-proof material. The components of the high-temperature-resistant slurry are: 75 parts by mass of ethanol, 13 parts of ether, 12 parts of 13 parts of ferrosilicon powder, 9 parts of ferronickel powder, 5 parts of copper powder, 6 parts of nitrocellulose, 18 parts of potassium silicate, 13 parts of butyl acetate; 4 parts of molybdenum, 10 parts of graphene oxide, 13 parts of silicon carbide, 6 parts of nano-alumina, 5 parts of titanium dioxide, 13 parts of lithium silicate, 65 parts of deionized water.

[0028] Among them, the preparation method of the high-temperature-resistant slurry is: according to the mass parts, ethanol, ether and butyl acetate are mixed to obtain an organic solvent, and then iron powder, sendust powder, nickel-iron powder and copper powder are mixed uniformly and added to the organic so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com