Halogen-free anti-flaming PC/ABS plastic alloy and preparation method thereof

A technology of ABS plastic and alloy, applied in the field of preparation of PC/ABS plastic alloy, can solve problems such as affecting the mechanical properties of PC/ABS plastic alloy, and achieve the effects of reducing the entry of external oxygen, promoting cross-linking, and preventing dripping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

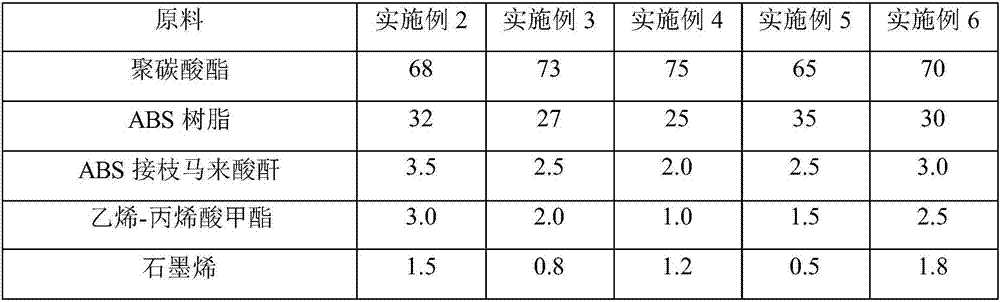

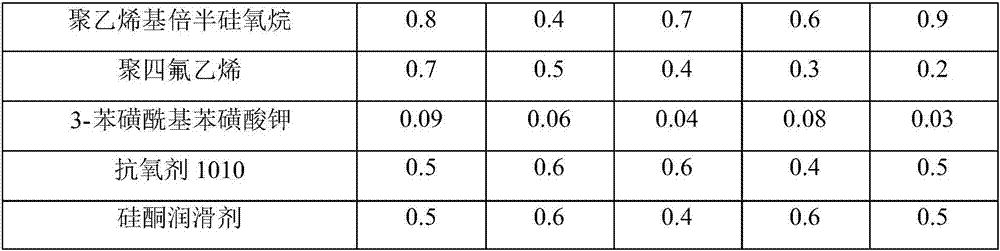

Examples

Embodiment 1

[0029] The halogen-free flame-retardant PC / ABS plastic alloy of this embodiment is mainly made of the following raw materials in parts by weight: 70 parts of polycarbonate, 30 parts of acrylonitrile-butadiene-styrene copolymer, ABS grafted horse 3.0 parts of anhydride copolymer compatibilizer, 2.0 parts of ethylene-methyl acrylate, 1.0 parts of graphene, 0.5 parts of polyvinylsilsesquioxane, 0.6 parts of polytetrafluoroethylene, potassium 3-benzenesulfonylbenzenesulfonate 0.05 parts, antioxidant 1010 0.5 parts, silicone lubricant 0.5 parts.

[0030] The preparation method of the halogen-free flame-retardant PC / ABS plastic alloy of the present embodiment comprises the following steps:

[0031] 1) get the graphene of 1.0 weight part, modify with silane coupling agent, obtain modified graphene;

[0032]2) get step 1) gained modified graphene, and 0.5 weight part of polyvinylsilsesquioxane, 0.6 weight part of polytetrafluoroethylene, 0.05 weight part of 3-benzenesulfonylbenzenesu...

experiment example 1

[0040] In this experimental example, the flame retardancy of the halogen-free flame-retardant PC / ABS plastic alloy products obtained in Examples 1-6 was tested, and the results are shown in Table 2.

[0041] Among them, the limiting oxygen index (LOI) is the lowest oxygen concentration that maintains the combustion of the sample in a specific experimental environment; it is tested by the method specified in the standard GB2406-93. Vertical burning test (UL 94) is tested according to the method specified in the standard GB / T2408-1996.

[0042] Table 2 embodiment 1-6 gained PC / ABS plastic alloy product flame retardant performance detection result

[0043] PC / ABS plastic alloy products

[0044] As can be seen from Table 2, the limited oxygen index of the PC / ABS plastic alloy products obtained in Examples 1-6 reaches more than 30vol%, and the vertical burning level reaches UL 94V-0, which shows that the PC / ABS plastic alloy of the present invention has significant resist...

experiment example 2

[0046] In this experimental example, the mechanical properties of the halogen-free flame-retardant PC / ABS plastic alloy products obtained in Examples 1-6 were tested, and the results are shown in Table 3.

[0047] Among them, impact strength and tensile strength are tested according to GB / T1043-93 and GB / T1040-92 standards respectively.

[0048] The mechanical performance detection result of the PC / ABS plastic alloy product of table 3 embodiment 1-6 gained

[0049] PC / ABS plastic alloy products

[0050] As can be seen from Table 3, the impact strength of the PC / ABS plastic alloy product obtained in Examples 1-6 is at 32kJ / m 2 Above, the tensile strength is above 51Mpa; combined with Table 2, it can be obtained that the PC / ABS plastic alloy of the present invention has both mechanical properties and flame-retardant properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| Combustion level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com