Paper chip for quick flow guidance and substance transportation, manufacturing method and application thereof

A microfluidic chip, physical method technology, applied in chemical instruments and methods, laboratory containers, material analysis by observing the effect on chemical indicators, etc., can solve the problem that wax-based chips cannot be bent and cannot be prepared. The problems of structure and lamination are not firm, so as to increase the effective transmission distance, reduce the adsorption loss, and speed up the transmission speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Manufacture of paper base-clear plastic tape composite microfluidic chip

[0035] Step 1. Use laser engraved filter paper to make paper chips (Whatman medium-speed quantitative filter paper) as the paper base, such as figure 1 shown;

[0036] Step 2. Use a laser engraving machine to engrave a polyethylene terephthalate (PET) plate mold with a width of 0.5mm and a depth of 0.5mm;

[0037] Step 3. Place the main micro-channel area in the middle of the paper chip obtained in step 1 on the groove of the mold, emboss the groove and seal the entire groove with plastic tape;

[0038] Step 4. Use scissors to cut off the excess part of the tape to obtain a paper-based-clear plastic tape composite microfluidic chip.

Embodiment 2

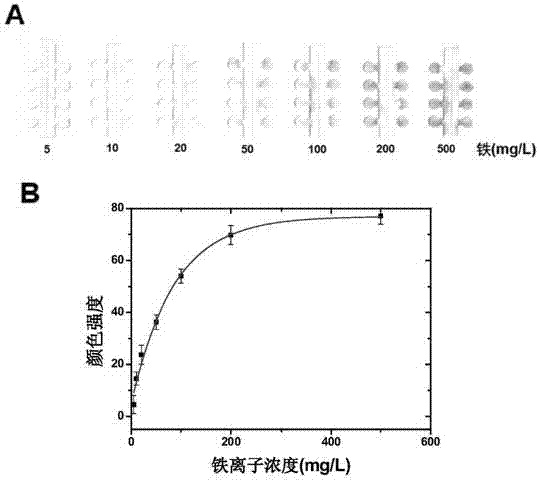

[0039] Example 2: Paper base-clear plastic tape composite microfluidic chip for simultaneous analysis of multiple ions

[0040] Step 1. making the paper chip with the four-order detection area in Example 1;

[0041] Step 2. preparation each concentration is respectively ferric chloride, nickel nitrate, ammonium dichromate, copper sulfate mixed standard solution of 0.1g / L;

[0042] Step 3. prepare the buffer solution of the 3M ammonium acetate of pH 4.5;

[0043] Step 4. prepare the hydroxylamine solution of 0.1g / ml and the 1,10-phenanthroline solution of 8mg / ml with the solution in step 3;

[0044] Step 5. prepare the polyacrylic acid solution of 0.7mg / ml;

[0045] Step 6. Prepare 0.5M NaF solution;

[0046] Step 7. prepare the buffer solution of the 3M sodium acetate of pH 4.5;

[0047] Step 8. preparation mass fraction is the dimethylglyoxime methanol solution of 1%;

[0048] Step 9. Prepare 0.03M ammonia solution;

Embodiment 3

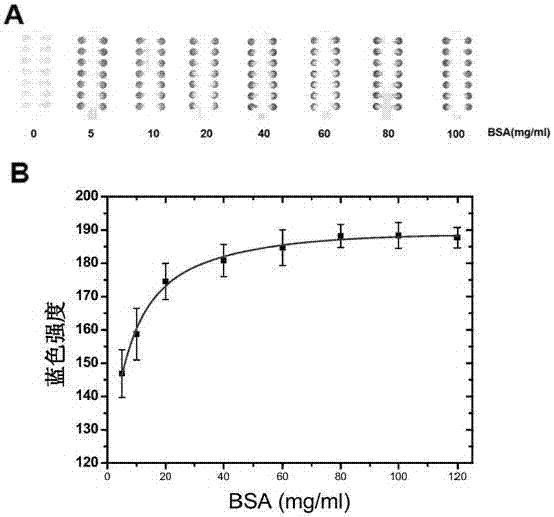

[0059] Example 3: Paper-base-clear plastic tape composite microfluidic chip for simultaneous analysis of multiple biomacromolecular proteins

[0060] Step 1. make the chip with seven-order detection area in embodiment 1;

[0061] Step 2. prepare bovine serum albumin (BSA) phosphate buffer (PBS) solution of 10mg / mL, 20mg / mL, 40mg / mL, 60mg / mL, 80mg / mL, 100mg / mL, 120mg / mL;

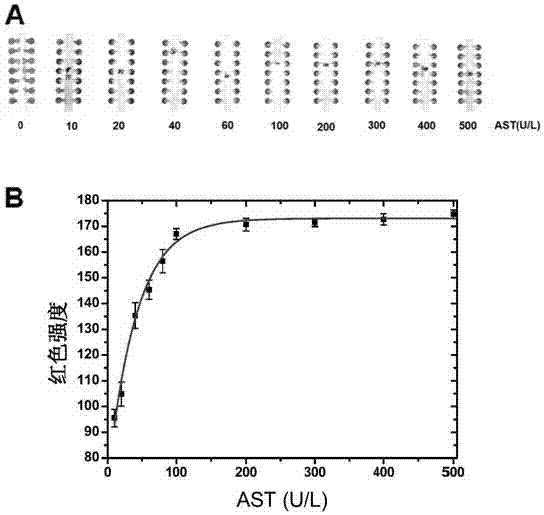

[0062] Step 3. Prepare aspartate aminotransferase (AST) phosphate buffer (PBS) of 10U / L, 20U / L, 40U / L, 60U / L, 80U / L, 100U / L, 200U / L, 300U / L, 500U / L solution;

[0063] Step 4. Prepare 50ml of 250mM citric acid buffer solution with pH 1.8 (containing a drop of polyethylene glycol octylphenyl ether (Triton X-100));

[0064] Step 5. Prepare 95% ethanol solution of 6mM tetrabromophenol blue;

[0065] Step 6. Prepare 10% trehalose aqueous solution;

[0066] Step 7. Dissolve 306mg of cysteine sulfinic acid, 34mg of α-ketoglutaric acid, and 1.6mg of ethylenediaminetetraacetic acid (EDTA) in 1ml of 400mM Tris so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com