Microspherical silica/alumina-based noble metal catalyst and preparation method thereof

A noble metal catalyst and noble metal technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem of weak silicon-aluminum bonding, lower specific surface area, and lower catalytic activity and other problems, to achieve the effect of high wear resistance, small wear index and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A. Dissolve 10.00 g of aluminum powder with an average particle size of 50 μm in 100.00 g of hydrochloric acid solution with a mass concentration of 10% to prepare an aluminum sol.

[0032] B. Add 4.47g Na 2 SiO 3 9H 2 O was dissolved in 5.00 g of deionized water and passed through 001×7 (732) type strongly acidic polystyrene cation exchange resin to obtain silica sol.

[0033] C. Fully mix the above two solutions, then add 32.18g of hexamethylenetetramine solution (40wt%), and stir evenly. It is delivered to the dispersing nozzle by a peristaltic pump at a flow rate of 20mL / min, and then injected into No. 25 transformer oil at a temperature of 80°C at a pressure of 0.15MPa for molding. The shaped microspheres were separated from the oil and aged in an oven at 130°C for 5h.

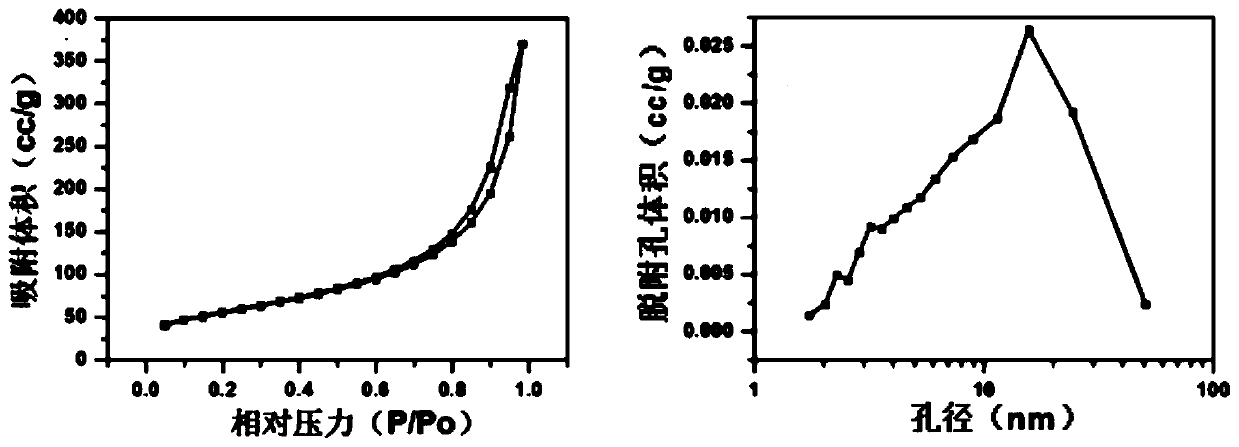

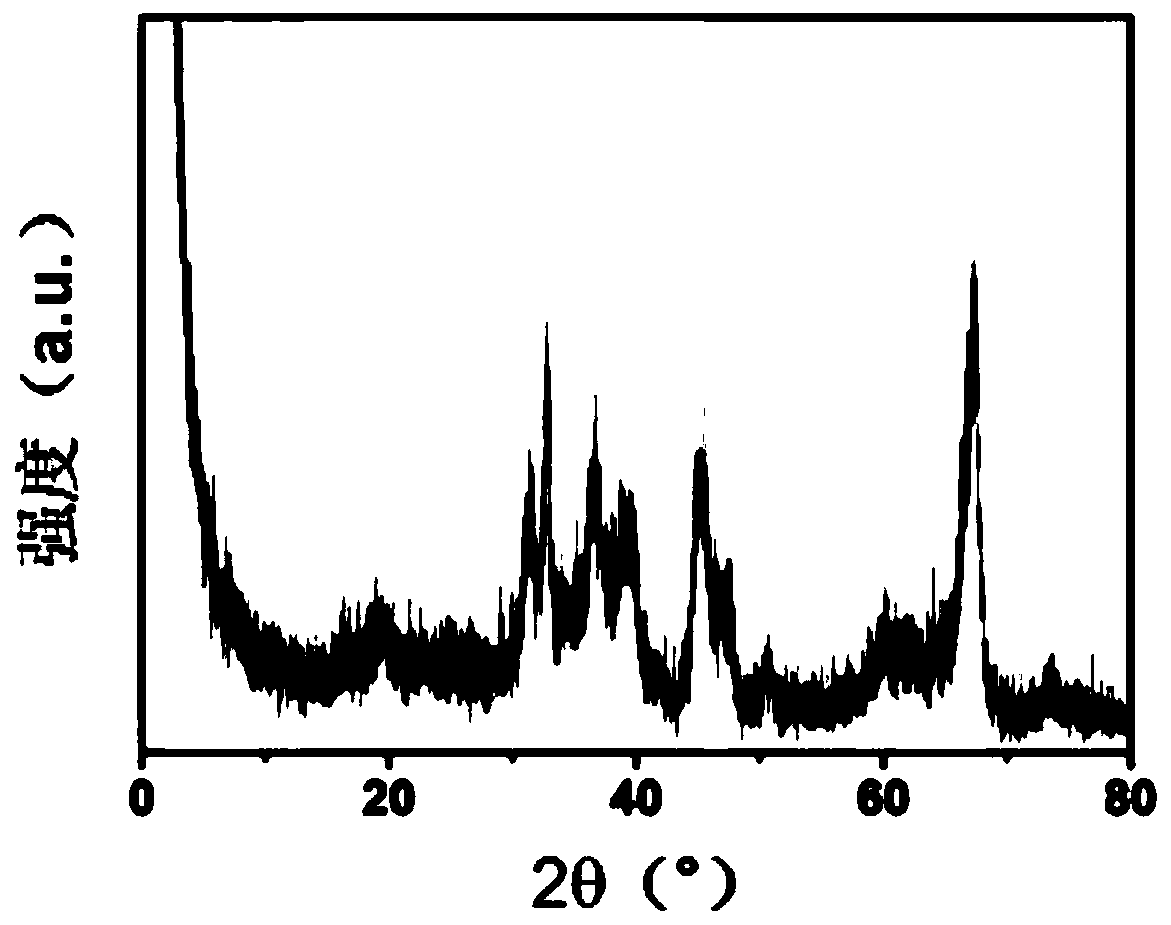

[0034] D. The above product is filtered and washed, dried at 90°C for 12h, and then roasted in a muffle furnace at 960°C for 4h to obtain SiO 2 4% Microspherical SiO 2 -Al 2 o 3 carrier.

...

Embodiment 2

[0041] A. Dissolving 12.00 g of aluminum powder with an average particle size of 50 μm in 100.00 g of hydrochloric acid solution with a mass concentration of 10% to prepare aluminum sol.

[0042] B. Add 6.86g Na 2 SiO 3 9H 2 O was dissolved in 7.00 g of deionized water and passed through 001×12 type strongly acidic polystyrene cation exchange resin to obtain silica sol.

[0043] C. Mix the above two solutions thoroughly, then add 34.32g of hexamethylenetetramine solution (40wt%), and stir evenly. It is delivered to the dispersing nozzle by a peristaltic pump at a flow rate of 20mL / min, and then injected into No. 25 transformer oil at a temperature of 80°C at a pressure of 0.15MPa for molding. The shaped microspheres were separated from the oil and aged in an oven at 130°C for 5h.

[0044] D. The above product is filtered and washed, dried at 90°C for 12h, and then roasted in a muffle furnace at 1000°C for 4h to obtain SiO 2 6% Microspherical SiO 2 -Al 2 o 3 carrier.

...

Embodiment 3

[0047] A. Dissolving 14.00 g of aluminum powder with an average particle size of 50 μm in 100.00 g of hydrochloric acid solution with a mass concentration of 10% to prepare aluminum sol.

[0048] B. Add 8.22g Na 2 SiO 3 9H 2 O was dissolved in 7.00 g of deionized water and passed through 7320 type strongly acidic polystyrene cation exchange resin to obtain silica sol.

[0049] C. Fully mix the above two solutions, then add 35.24g of hexamethylenetetramine solution (40wt%), and stir evenly. It is delivered to the dispersing nozzle by a peristaltic pump at a flow rate of 20mL / min, and then injected into No. 25 transformer oil at a temperature of 80°C at a pressure of 0.15MPa for molding. The shaped microspheres were separated from the oil and aged in an oven at 130°C for 5h.

[0050] D. The above product was filtered and washed, dried at 90°C for 12h, and then calcined in a muffle furnace at 1050°C for 4h to obtain SiO 2 8% Microspherical SiO 2 -Al 2 o 3 carrier.

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com