Wear-resistant zirconium-aluminum composite ball and preparation method thereof

A technology of wear-resistant zirconium aluminum and composite balls, which is applied in the field of grinding media, can solve the problems of high cost, high firing temperature, and low cost, and achieve the effects of increasing toughness and strength, stable chemical properties, and reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Grinding: 3000kg of aluminum hydroxide balls, 2700kg of alumina powder, 300kg of zirconia, 7350kg of waste ceramic rollers, 750kg of kaolin, 450kg of dolomite, 300kg of calcined talc, 225kg of barium carbonate, 7500kg of water, and 25kg of citric acid. 1. Put water into the ball mill and grind for 25 hours until the particle size is D90<10μm. Put the mud into the primary mud pool. After the primary mud is fully stirred, put it into the secondary mill and grind until D90<5.5μm, PVA30kg, water 300kg The proportion of boiling without suspended solids, adding ball mill grinding for 1.5 hours, adding dispersant 40kg, continue grinding for 15 minutes and put it into the secondary mud pool;

[0039] (2) Milling: beat the secondary mud into the servo tank, stir and mix the mud, use the plunger pump to pump the mud into the spray tower for granulation, control the water content to less than 1%, and make granulated powder with a particle size of 0.1-0.5 ;

[0040] (3) Compre...

Embodiment 2

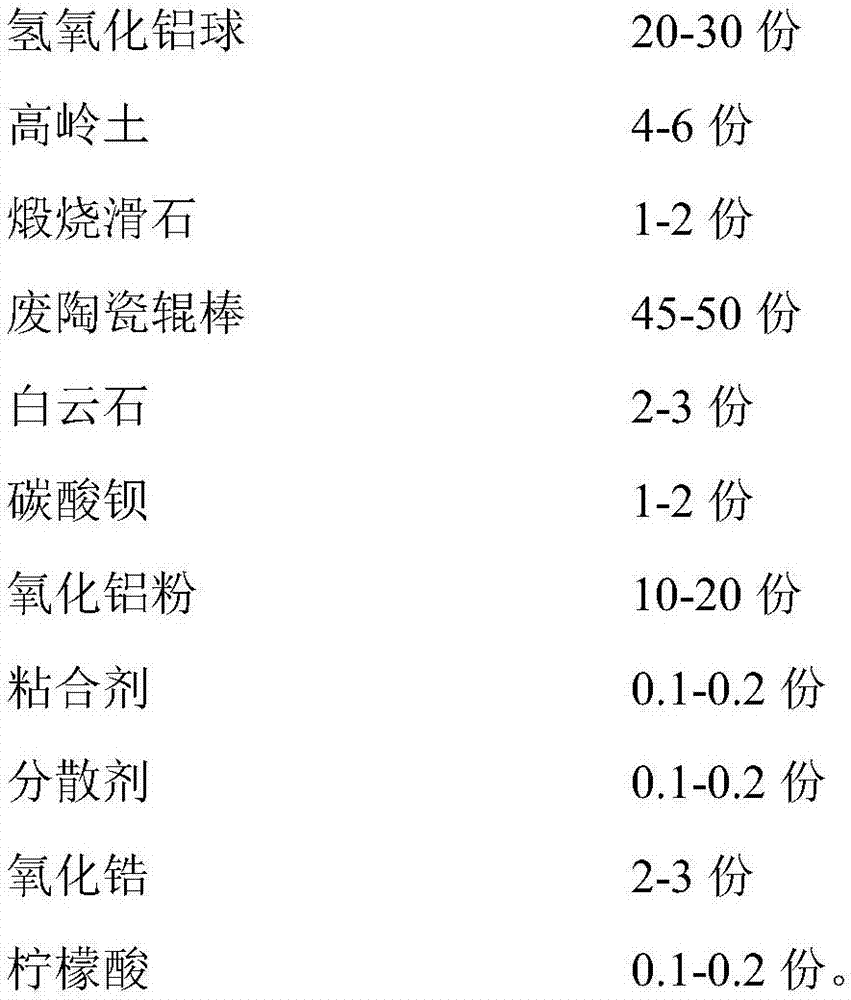

[0046] (1) Grinding: 20kg of aluminum hydroxide balls, 20kg of alumina powder, 2kg of zirconia, 45kg of waste ceramic rollers, 6kg of kaolin, 3kg of dolomite, 2kg of calcined talc, 2kg of barium carbonate, 0.16kg of citric acid, and 50kg of water. Put the raw materials and water into the ball mill and grind for 25 hours until the particle size is D90<10μm. Put the mud into the primary mud pool. After the primary mud is fully stirred, put it into the secondary mill and grind until D90<5.5μm, PVA0.2kg , the proportion of water 2kg boiled without suspended solids, added ball mill to grind for 1.5 hours, added dispersant 0.2kg, continued to grind for 15 minutes and then put it into the secondary mud pool;

[0047] (2) Milling: beat the secondary mud into the servo tank, stir and mix the mud, use the plunger pump to pump the mud into the spray tower for granulation, control the water content to less than 1%, and make granulated powder with a particle size of 0.1-0.5 ;

[0048] (3)...

Embodiment 3

[0053] (1) Grinding: 30kg of aluminum hydroxide balls, 10kg of alumina powder, 2kg of zirconia, 49kg of waste ceramic rollers, 4kg of kaolin, 2kg of dolomite, 1kg of calcined talc, 1kg of barium carbonate, 0.1kg of citric acid, 1.2kg of water, Put the raw materials and water into the ball mill and grind for 25 hours until the particle size is D90<10μm. Put the mud into the primary mud pool. After the primary mud is fully stirred, put it into the secondary mill and grind until D90<5.5μm, PVA0. 2kg, 2kg of water to cook without suspended solids, add ball mill to grind for 1.5 hours, add 0.1kg of dispersant, continue grinding for 15 minutes, and then put it into the secondary mud pool;

[0054] (2) Milling: beat the secondary mud into the servo tank, stir and mix the mud, use the plunger pump to pump the mud into the spray tower for granulation, control the water content to less than 1%, and make granulated powder with a particle size of 0.1-0.5 ;

[0055] (3) Compression moldin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com