Heat management system and method of power battery pack

A technology of battery management system and thermal management system, applied in secondary batteries, secondary battery repair/maintenance, battery/fuel cell control devices, etc., can solve problems such as low efficiency, uneven temperature distribution, thermal runaway, etc., to achieve Unified thermal management of heating and cooling, convenient switching of current direction, fast cooling and heating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

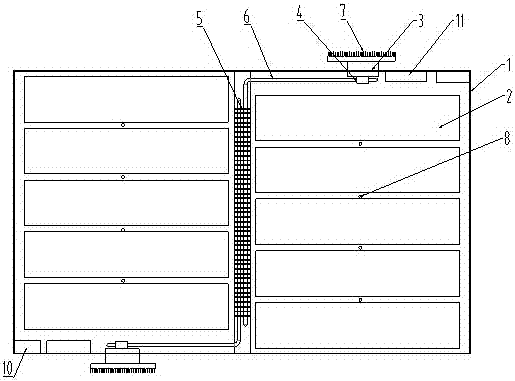

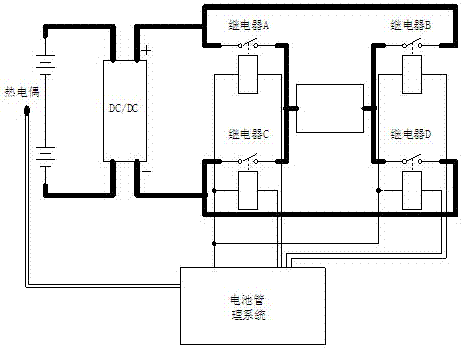

[0025] Such as figure 1 and figure 2 As shown, a thermal management system of a power battery pack includes a thermistor 8 , a semiconductor refrigeration device 3 , a heat pipe 6 , a circuit control device and a battery management system 11 .

[0026] Both the thermistor 8 and the heat pipe 6 are installed in the battery case 1, and are located between the battery modules 2, the thermistor 8 is not less than two, and the adjacent battery modules 2 are installed With thermistor 8;

[0027] The heat pipe 6 is an L-shaped heat pipe, one end of the heat pipe 6 is connected to the heat absorbing sheet 5 located in the center of the battery case 1, and the other end is connected to the semiconductor refrigeration device 3 installed on the outside of the battery case 1 through the aluminum plate 4. The device 3 is connected to the power converter 10 through a circuit control device; the heat pipe 6 and the semiconductor refrigeration device 3 are provided with two groups, and the...

Embodiment 2

[0031] A management method for a thermal management system of a power battery pack, comprising the following steps:

[0032] S1, the thermistor 8 detects the temperature inside the battery box 1;

[0033] S2. When the temperature detected by the thermistor 8 exceeds the preset value of the battery management system 11, the battery management system 11 outputs a positive DC voltage by closing relay A and relay D, and starts the semiconductor cooling mode, that is, the air in the battery box and the The heat-absorbing sheet 5 and the heat pipe 6 exchange heat, transfer the heat to the aluminum plate 4, and exchange heat again through the cold end of the semiconductor refrigeration device 3, and the heat moves to the hot end through the thermoelectric cooling effect, and the hot end of the semiconductor refrigeration device 3 and the The heat sink 7 is connected, and the heat sink 7 dissipates heat to the environment through convection heat exchange with the natural wind when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com