A kind of water-based inorganic zinc-rich primer and preparation method thereof

An inorganic zinc-rich and primer technology, applied in coatings, anti-corrosion coatings, alkali metal silicate coatings, etc., can solve the problems of reduced structural strength, high construction costs, and long-term maintenance inconvenience, and achieve reduced construction costs and weather resistance Good performance and easy long-term maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

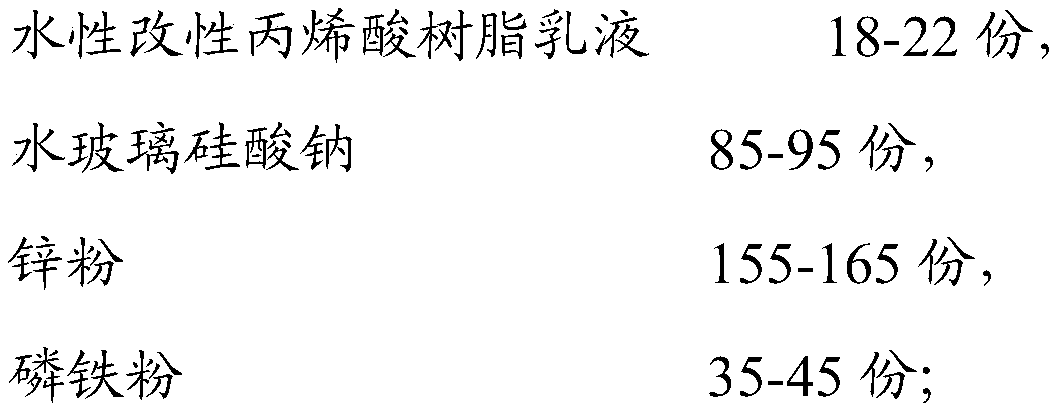

[0034] Preparation of waterborne inorganic zinc-rich primer S-01

[0035] S101. Preparation of functional monomers: react 3 mol of polyether PPG800 with 2 mol of diphenylmethane diisocyanate to prepare an elastomer with a degree of polymerization of terminal hydroxyl groups of 3. The reaction equation is:

[0036] , the prepared elastomer is abbreviated as OH-P-OH; react 2mol elastomer with 1mol maleic anhydride to obtain functional monomer, and the reaction equation is:

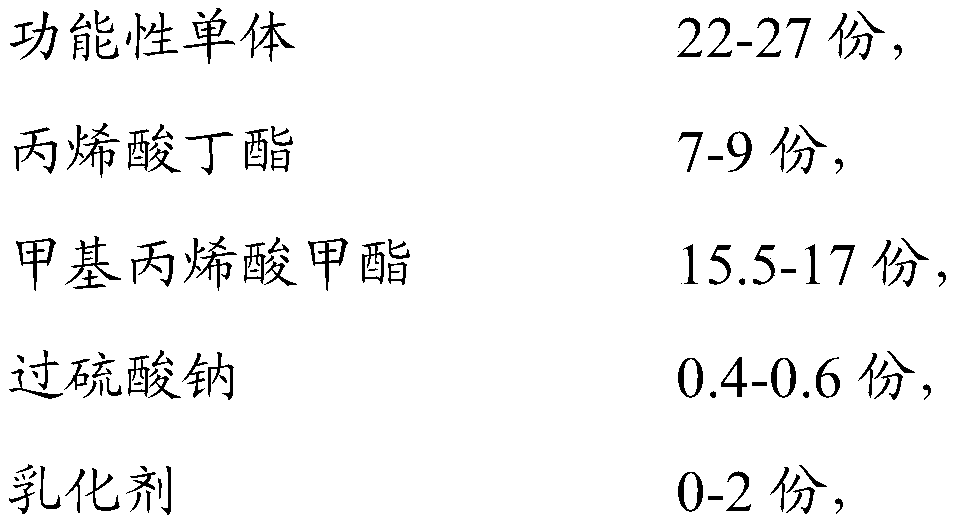

[0037] S102. the preparation of water-based modified acrylic resin emulsion, comprising:

[0038] a) Add 0.2g of alkylphenol polyoxyethylene ether and 30g of water into the reactor and stir evenly, raise the temperature to 78°C, and keep it warm;

[0039] b) dissolving 0.4g of sodium persulfate in 15g of water to obtain an aqueous solution of sodium persulfate, and dividing the aqueous solution of sodium persulfate into 4 parts, and adding 1 part thereof to the reaction kettle;

[0040] c) Mix 22g of f...

Embodiment 2

[0044] Preparation of waterborne inorganic zinc-rich primer S-02

[0045] S101. Preparation of functional monomers: react 3 mol of polyether PPG800 with 2 mol of diphenylmethane diisocyanate to prepare an elastomer with a terminal hydroxyl polymerization degree of 3, and the reaction equation is: , the prepared elastomer is abbreviated as OH-P-OH; react 2mol elastomer with 1mol maleic anhydride to obtain functional monomer, and the reaction equation is:

[0046] S102. the preparation of water-based modified acrylic resin emulsion, comprising:

[0047] a) Add 45g of water into the reactor, raise the temperature to 80°C, and keep it warm;

[0048] b) dissolving 0.4g of sodium persulfate in 5g of water to obtain an aqueous solution of sodium persulfate, and dividing the aqueous solution of sodium persulfate into 4 parts, and adding 1 part thereof to the reaction kettle;

[0049] c) Mix 23g of functional monomer, 8g of butyl acrylate, and 15.5g of methyl methacrylate evenly f...

Embodiment 3

[0053] Preparation of waterborne inorganic zinc-rich primer S-03

[0054]S101. Preparation of functional monomers: react 3 mol of polyether PPG800 with 2 mol of diphenylmethane diisocyanate to prepare an elastomer with a degree of polymerization of terminal hydroxyl groups of 3. The reaction equation is: , the prepared elastomer is abbreviated as OH-P-OH; react 2mol elastomer with 1mol maleic anhydride to obtain functional monomer, and the reaction equation is:

[0055] S102. the preparation of water-based modified acrylic resin emulsion, comprising:

[0056] a) Add 1g of alkylphenol polyoxyethylene ether and 40g of water into the reactor and stir evenly, raise the temperature to 80°C, and keep it warm;

[0057] b) dissolving 0.5 g of sodium persulfate in 10 g of water to obtain an aqueous solution of sodium persulfate, and dividing the aqueous solution of sodium persulfate into 5 parts, and adding 1 part thereof to the reaction kettle;

[0058] c) Mix 25g of functional m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com