Method for initiating polymerization of epoxy monomer by using graphene oxide as initiator

A technology of monomer polymerization and epoxy, which is applied in the field of graphene oxide modification, can solve problems such as poor interface compatibility and complex reaction process, and achieve the effects of improving dispersion, simplifying the preparation process, and improving interface interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of method using graphene oxide as initiator to initiate epoxy monomer polymerization, comprises the steps:

[0036] Step 1: Preparation of Graphene Oxide

[0037] Adopt Hummers method or improved Hummers method to prepare graphene oxide and grind into powder, concrete preparation is as follows:

[0038] (1) Get 10g potassium thiosulfate (K 2 S 2 o 8 ) and 10g phosphorus pentoxide (P 2 o 5 ) was successively added to 50ml of concentrated sulfuric acid (98%) in an oil bath at 80°C, with 0.8 to 1.2 parts of potassium thiosulfate per 1 part of graphite powder, and 0.8 to 1.2 parts of potassium thiosulfate per 1 part of graphite powder. Add graphite powder according to the proportion of phosphorus oxide, and stir magnetically at 80°C for 4.5 hours. After the reaction is completed, wait for the reaction solution to cool to room temperature, add it to 2L of deionized water for dilution, and vacuum filter the reaction solution after standing for more than 12 hours. ...

Embodiment 2

[0048] A kind of method using graphene oxide as initiator to initiate epoxy monomer polymerization, comprises the steps:

[0049] Step 1: Preparation of Graphene Oxide

[0050] Same as Step 1 in Example 1.

[0051] Step 2: Graphene oxide initiates the polymerization of epichlorohydrin

[0052] (1) Add 59mg of graphene oxide into the reaction flask, add 0.32ml of ethylene glycol with a syringe, fully mix with graphene oxide under the action of magnetic stirring, and add 10ml of epichlorohydrin monomer drop by drop Put it into the reaction bottle, after 1h dripping, the temperature is raised to 60°C for reaction, and the reaction time is 48h;

[0053] (2) After the reaction, take 400ml of ether as a precipitant, drop the reaction solution into the precipitant, let it stand for 24 hours, pour off the supernatant, separate the precipitated part and dry it in a vacuum oven to obtain the product.

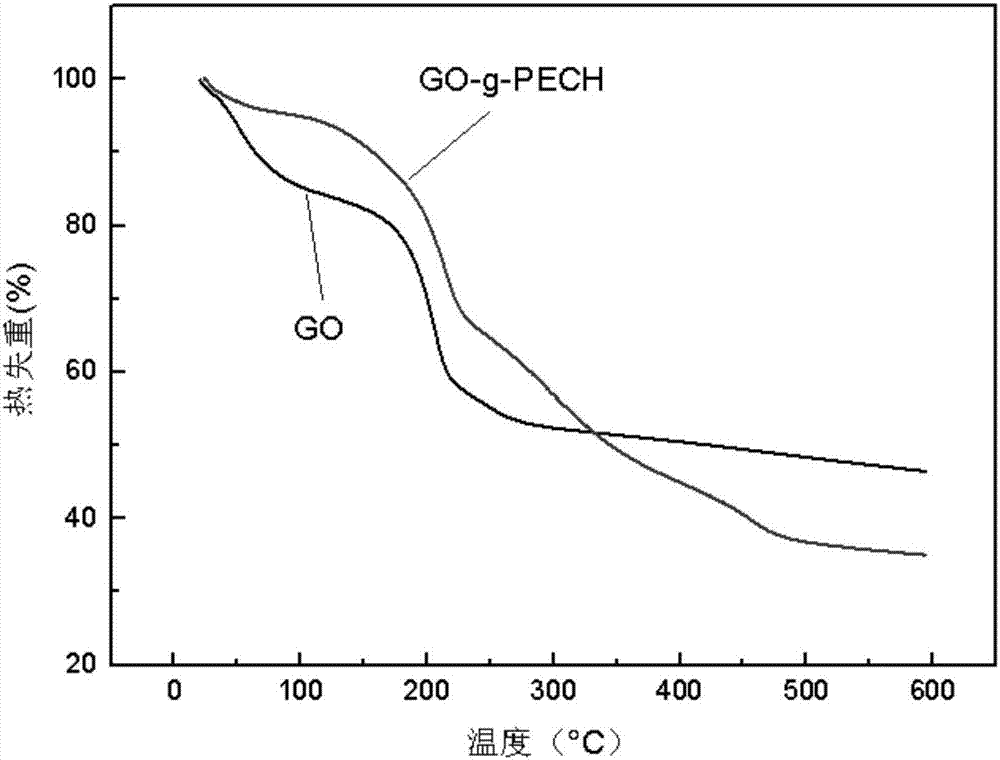

[0054] (3) Dispersing the obtained product in a tetrahydrofuran solution, centrifu...

Embodiment 3

[0058] A kind of method using graphene oxide as initiator to initiate epoxy monomer polymerization, comprises the steps:

[0059] Step 1: Preparation of Graphene Oxide

[0060] Same as Step 1 in Example 1.

[0061] Step 2: Graphene oxide initiates the polymerization of 3-hydroxypropylene oxide

[0062] (1) Add 55 mg of graphene oxide to the reaction flask, 10 ml of 3-hydroxypropylene oxide, and add it dropwise to the reaction flask. After 1 hour of dripping, the temperature is raised to 40 ° C for reaction. The monomer and graphene oxide are fully mixed, and the reaction time is 24h;

[0063] (2) After the reaction, take 400ml of ether as a precipitant, drop the reaction solution into the precipitant, let it stand for 24 hours, pour off the supernatant, separate the precipitated part and dry it in a vacuum oven to obtain the product.

[0064] (3) Dispersing the obtained product in a tetrahydrofuran solution, centrifuging and washing with tetrahydrofuran repeatedly for 5 tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grafting amount | aaaaa | aaaaa |

| grafting amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com