Preparation method of graphene material resistance type gas sensing array and application method thereof

A technology of gas sensing and graphene, which is applied in the direction of analyzing materials, material resistance, chemical instruments and methods, etc., to achieve the effects of excellent gas sensing performance, favorable adsorption and diffusion, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

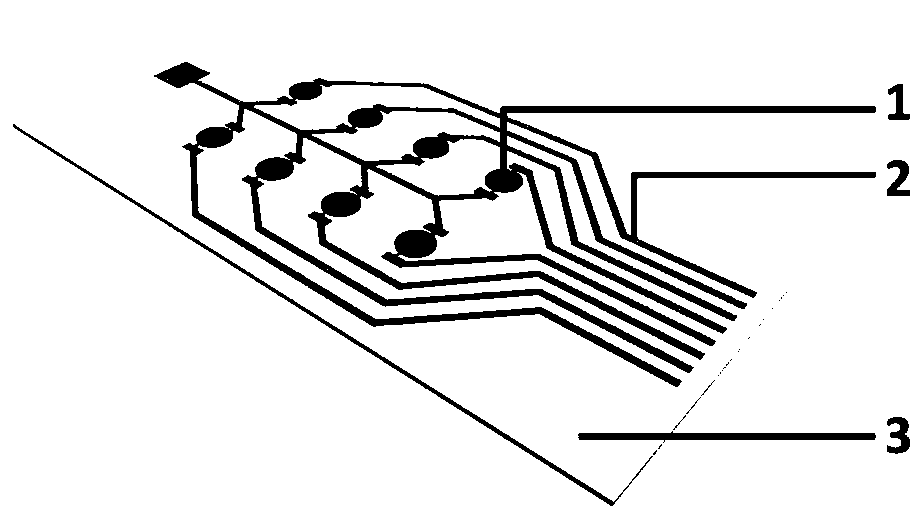

[0039] The invention discloses a method for preparing a graphene material resistive gas sensing array, which specifically includes the following steps:

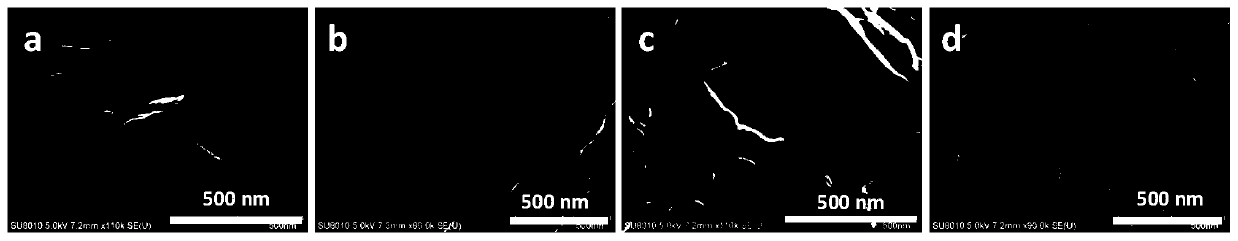

[0040] Step 1: Add the metal salt solution to the graphene oxide solution, adjust the pH value of the mixed solution and perform ultrasonic dispersion, incubate the mixed solution on a shaker for 4-12 hours, wash it with deionized water until neutral, and then wash it with deionized water Disperse to obtain graphene oxide self-assembly suspension, change the ratio of metal salt solution and graphene oxide solution or change the type of metal salt solution and repeat the above process to configure multiple graphene oxide self-assembly suspensions, graphene oxide self-assembly The number of parts of the suspension is the same as the number of sites of the multi-site forked electrode array. Multiple parts of graphene oxide self-assembly suspensions are obtained by adding different metal salt solutions or changing the ratio of me...

Embodiment 1

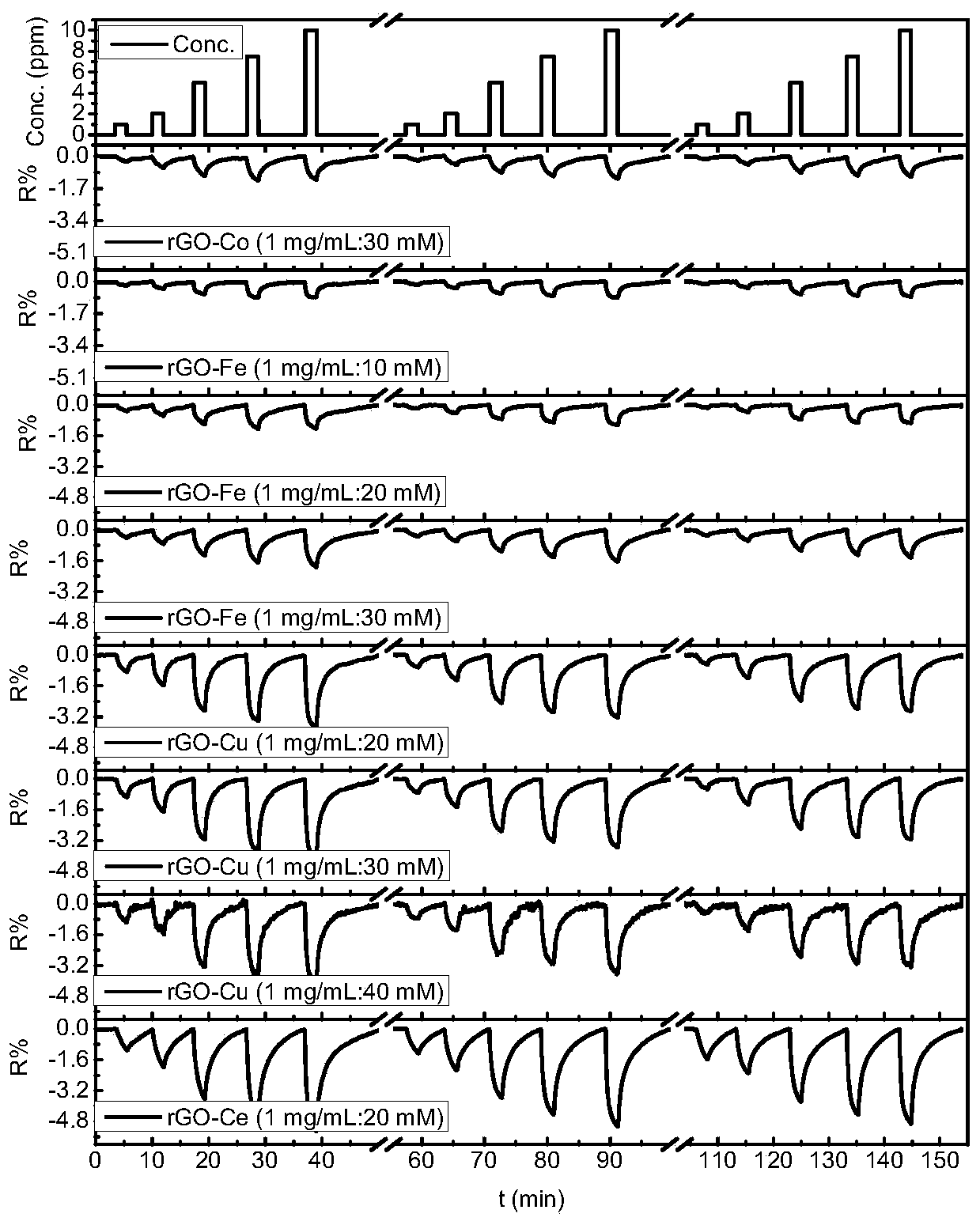

[0050] This embodiment provides a method for preparing a three-site graphene material resistive gas sensing array using a cobalt chloride solution, and the specific steps are as follows:

[0051] Step 1, adding the cobalt chloride solution to the graphene oxide solution, the ratios of graphene oxide and cobalt chloride in the mixed solution are 1mg / mL: 15mM, 1mg / mL: 30mM, 1mg / mL: 45mM, adjust three The pH value of the mixed solution was 7.0 for ultrasonic dispersion. The three mixed solutions were incubated on a shaker for 8 hours, washed with deionized water to neutrality, and then dispersed with deionized water to obtain three kinds of cobalt ion-induced graphene oxide self-assembly Suspension.

[0052] Step 2: Add 5 μL of the three graphene oxide self-assembled suspensions prepared in Step 1 to the fingers of the three-point forked electrode array and dry naturally. The distance between the fingers is 100 μm. The array was placed in hydrazine hydrate vapor and reduced at 8...

Embodiment 2

[0054] This embodiment provides a method for preparing a five-site graphene material resistive gas sensing array using ferric chloride solution, and the specific steps are as follows:

[0055] Step 1, adding the ferric chloride solution to the graphene oxide solution, the ratios of graphene oxide and ferric chloride in the mixed solution are 1mg / mL: 5mM, 1mg / mL: 10mM, 1mg / mL: 20mM, 1mg / mL : 30mM, 1mg / mL: 40mM, adjust the pH value of the five mixed solutions to 3.0 and carry out ultrasonic dispersion, incubate the five mixed solutions on a shaker for 6 hours, wash with deionized water until neutral, and then wash with deionized water Disperse to obtain five iron ion-induced graphene oxide self-assembly suspensions.

[0056] Step 2: Add 2.5 μL of the five graphene oxide self-assembled suspensions prepared in step 1 to the fingers of the five-point fork-shaped electrode array and dry naturally. The distance between the fingers is 100 μm. The electrode array was placed in hydrazi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com