Surface modification method for spherical superfine aluminum powder and modification equipment for surface modification method

A surface modification, aluminum powder technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of uneven packaging of organic films, large demand for organic reagents, harsh reaction conditions, etc., to achieve simple structure, low cost, Effects with low environmental requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

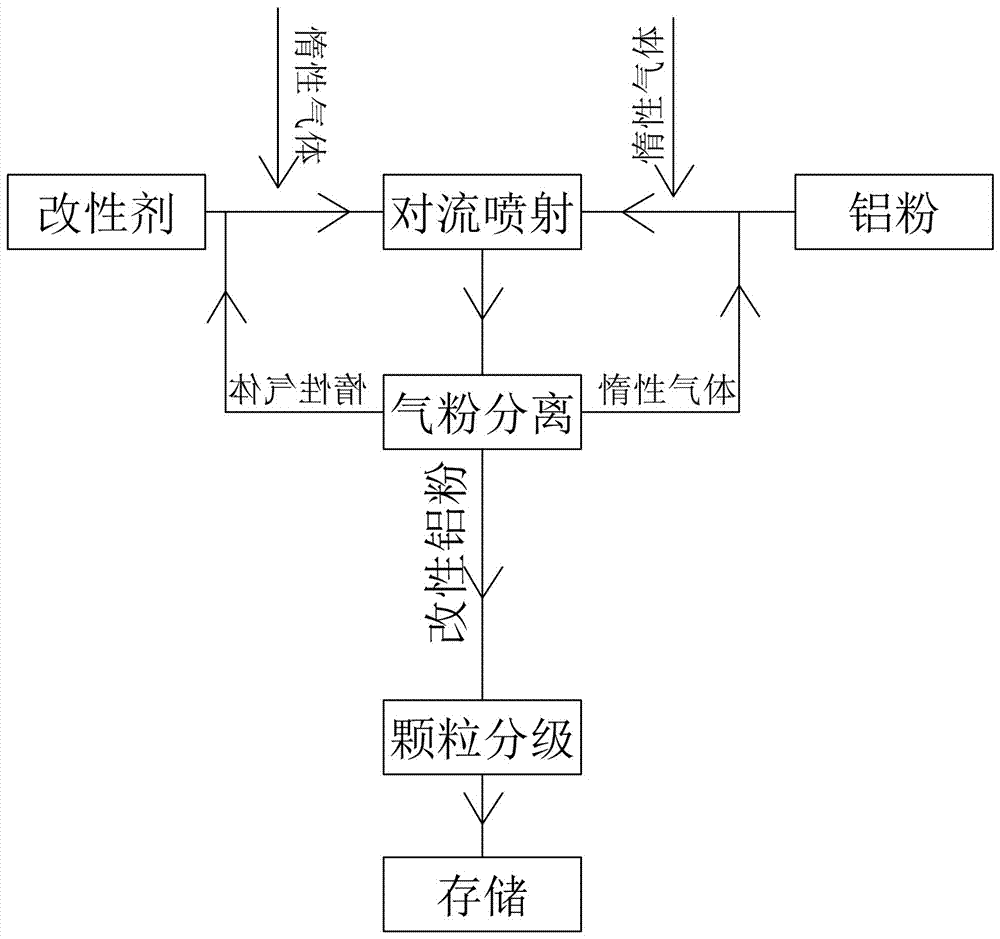

[0025] Such as figure 1 , figure 2 Shown, a kind of surface modification method of spherical ultrafine aluminum powder, weighing aluminum powder and modifier by mass ratio, described modifier is liquid modifier, and the mass ratio of modifier and aluminum powder is 0.5 : 100, the weighed aluminum powder and liquid modifier are sprayed under the protection of inert gas respectively. During the convective spraying process, the atomized liquid modifier is wrapped on the surface of the atomized aluminum powder particles to form a core / shell structure The composite particle structure realizes the surface modification of aluminum powder, and then, the inert gas dedusts and recycles, and the modified aluminum powder settles and is classified before storage. Described modifying agent is liquid modifying agent and is stearic acid.

[0026] A spherical ultrafine aluminum powder surface modification equipment, comprising a mixing tower 1, an aluminum powder tank 2, a modifier storage ...

Embodiment 2

[0029] Repeat Example 1 with the following differences. In this example, the mass ratio of the liquid modifier to the aluminum powder is 0.1:100, and the liquid modifier used is sodium oleate.

Embodiment 3

[0031] Repeat Example 1 with the following differences. In this example, the mass ratio of the liquid modifier to the aluminum powder is 10:100, and the liquid modifier used is polyvinyl alcohol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com